Non-alkali glass composition of high specific modulus value and its use

A glass composition and glass technology, applied in the field of alkali-free glass composition, can solve the problems of high glass density, unfavorable glass Young's modulus, and unfavorable light weight of flat-panel display panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-33

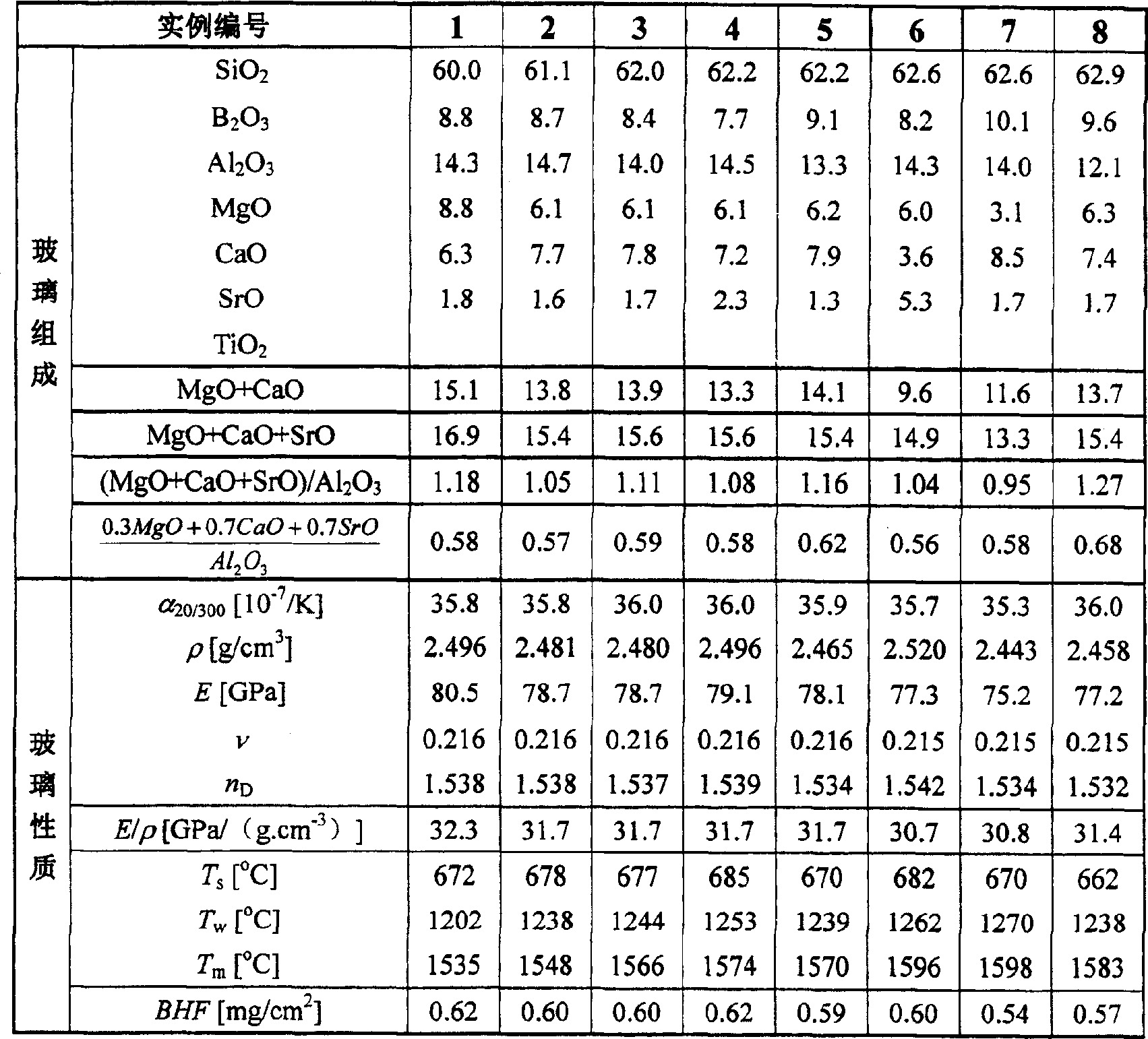

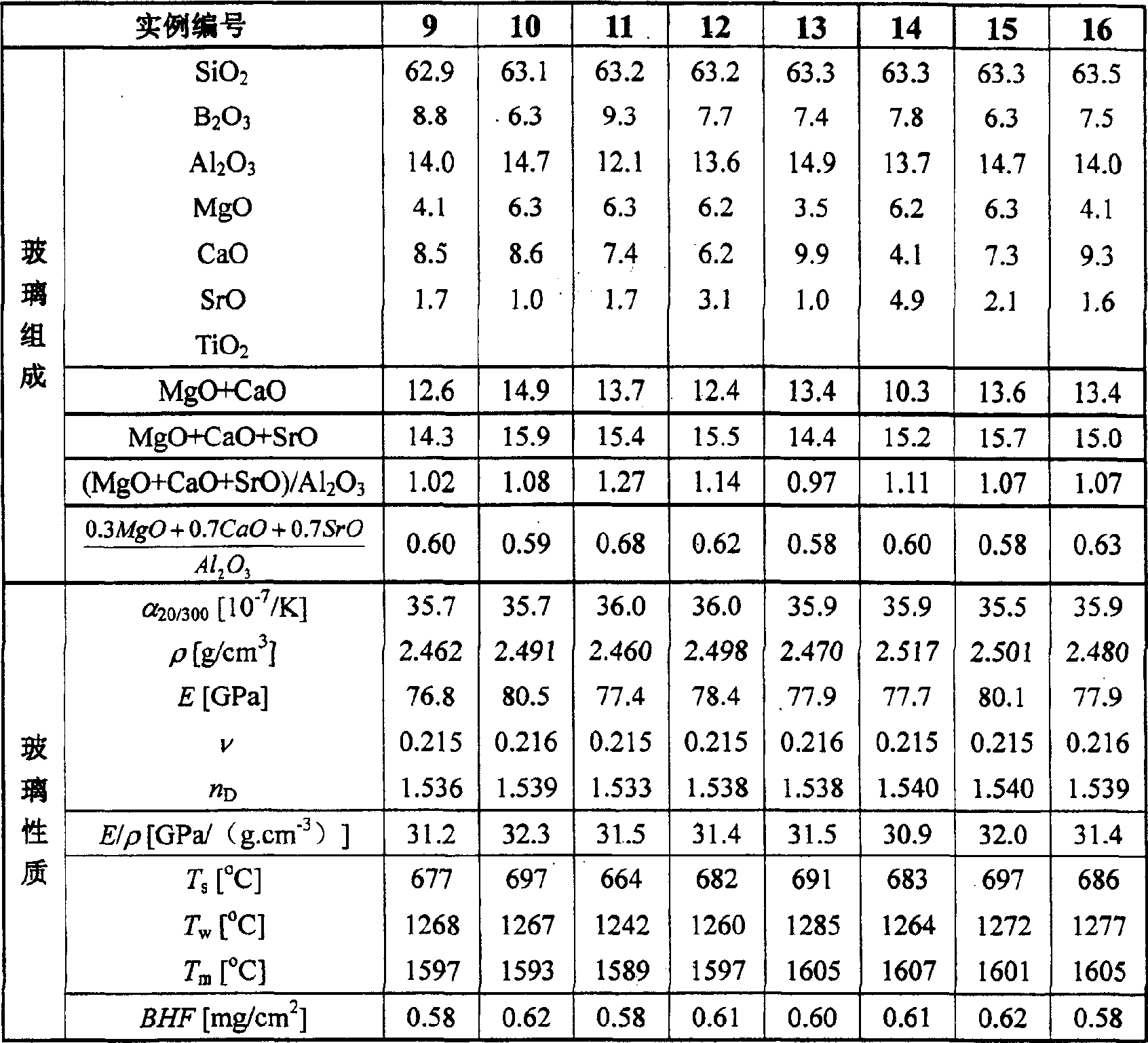

[0040] In Examples 1-33, glass compositions were prepared according to the composition shown in Table 1-4, and their properties were tested. Tables 1 to 4 summarize the composition of the glass of the present invention, and some fining agents in the melting process are not listed in the table.

[0041] The glass of Example 1-33 is composed of ingredients as shown in Table 1-4. Each pair weighs 400g. The glass ingredients are placed in a platinum rhodium crucible and melted in a high-temperature silicon-molybdenum rod electric furnace for 1.5 hours. The melting temperature 1520-1600°C. Table 1 to Table 4 also lists the glass properties. Glass properties include:

[0042] (1) 20-300℃ average thermal expansion coefficient α 20 / 300 [10 -7 / K];

[0043] (2) Density ρ[g / cm 3 ];

[0044] (3) Young's modulus E[GPa];

[0045] (4) Poisson's ratio v,

[0046] (5) Refractive index n D ;

[0047] (6) The calculated specific modulus value E / ρ[GPa / (g.cm -3 )];

[0048] (7) Strain point T s [℃], ...

Embodiment 34-66

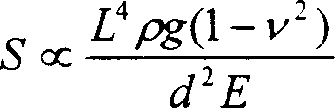

[0068] Using the glass composition of Example 1-33, at 1520 to 1650°C (the melting temperature of each glass is based on the T of Example 1-33 m The temperature is determined) melting limit for 2 hours, molding at 1200-1300 ℃ (each glass molding temperature according to the T of Example 1-33 wThe temperature is determined), and the glass plate is made according to the ordinary float process. The size of the glass plate is 680×880mm, and the thickness is 0.7mm and 1.1mm respectively. Two long sides and one short side of each glass plate were supported. At room temperature and normal conditions, after 0.5 hours, the maximum sag of the unsupported short sides are shown in Table 5. It can be seen from the table that the amount of glass sag is inversely proportional to the specific modulus of the glass.

[0069] Example number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain point | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com