Carbon fiber cloth-titanium alloy composite material and preparation method thereof

A technology of carbon fiber cloth and composite materials, which is applied in the field of metallurgy, can solve the problems of poor bonding, poor wettability of carbon fiber and titanium alloy, etc., and achieve the effects of high density, good interface bonding, and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

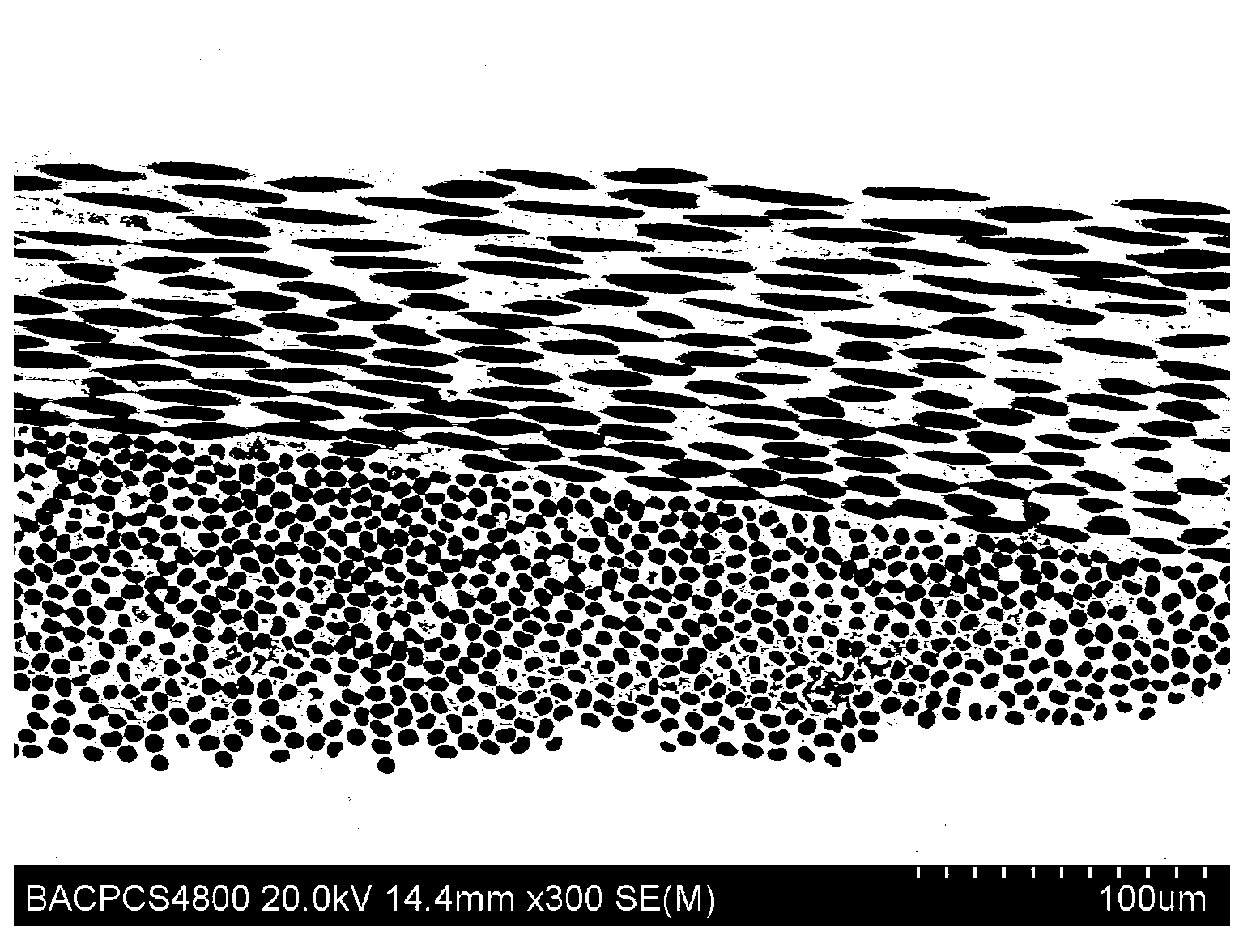

Image

Examples

Embodiment 1

[0024] 1. Cut the carbon fiber cloth into a square piece with a length of 10cm×10cm, and use the air burning method to remove the glue, and then use a 50% nitric acid aqueous solution to roughen it for 10 hours, take it out and wash it with deionized water 3 times;

[0025] 2. The surface of carbon fiber is copper-plated by electroplating, and the composition of the plating solution is CuSO 4 (150g / L), H 2 SO 4 (50g / L), distilled water; current density is 3A / dm 2 , the frequency is 1000 Hz, the duty cycle is 80%, the rotation speed is 60 rpm, the plating temperature is 20°C, and the plating time is 2h; after taking it out, wash it with deionized water for 3 times, and then dry it in hot air at 80°C;

[0026] 3. Cut TC4 titanium alloy (aluminum: 6%, vanadium: 4%, titanium remaining) and copper-plated carbon fiber cloth into the required shape, size and quantity, and distribute them in the SPS mold according to the requirements of the finished product;

[0027] 4. Place the i...

Embodiment 2

[0029] 1. Cut the carbon fiber cloth into a square piece with a length of 10cm×10cm, and use the air burning method to remove the glue, and then use a 50% nitric acid aqueous solution to roughen it for 10 hours, take it out and wash it with deionized water 3 times;

[0030] 2. The surface of carbon fiber is copper-plated by electroplating, and the composition of the plating solution is CuSO 4 (150g / L), H 2 SO 4 (50g / L), distilled water; current density is 1A / dm 2 , the frequency is 1000 Hz, the duty cycle is 80%, the rotation speed is 60 rpm, the plating temperature is 20°C, and the plating time is 2h; after taking it out, wash it with deionized water for 3 times, and then dry it in hot air at 80°C;

[0031] 3. Cut TC4 titanium alloy (aluminum: 6%, vanadium: 4%, titanium remaining) and copper-plated carbon fiber cloth into the required shape, size and quantity, and distribute them in the SPS mold according to the requirements of the finished product;

[0032] 4. Place the i...

Embodiment 3

[0034] 1. Cut the carbon fiber cloth into a square piece with a length of 10cm×10cm, and use the air burning method to remove the glue, and then use a 50% nitric acid aqueous solution to roughen it for 10 hours, take it out and wash it with deionized water 3 times;

[0035] 2. The surface of carbon fiber is copper-plated by electroplating, and the composition of the plating solution is CuSO 4 (150g / L), H 2 SO 4 (50g / L), distilled water; current density is 3A / dm 2 , the frequency is 1000 Hz, the duty cycle is 80%, the rotation speed is 60 rpm, the plating temperature is 30°C, and the plating time is 2h; after taking it out, wash it with deionized water for 3 times, and then dry it in hot air at 80°C;

[0036] 3. Cut TC4 titanium alloy (aluminum: 6%, vanadium: 4%, titanium remaining) and copper-plated carbon fiber cloth into the required shape, size and quantity, and distribute them in the SPS mold according to the requirements of the finished product;

[0037] 4. Place the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com