Method for manufacturing carbon fiber arm support for concrete pump truck

A concrete pump truck, carbon fiber technology, applied in the field of composite materials, can solve the problems of heavy weight, poor mobility, corrosion, etc., and achieve the effects of high specific strength, superior performance, and large specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

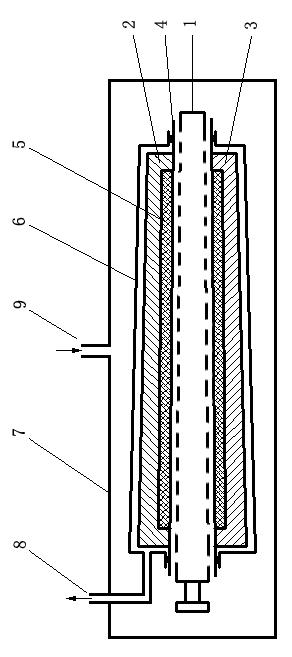

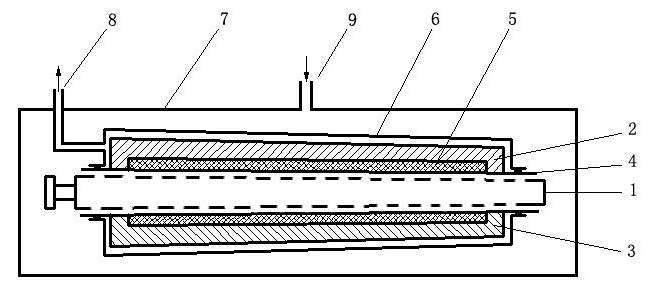

[0011] Such as figure 1 As shown, the present embodiment is provided with a mandrel 1, the vacuum film 4 is wrapped on the mandrel 1, the upper die 2 and the lower die 3 are combined on the mandrel 1, and the carbon fiber preformed The impregnating material 5 is spread between the vacuum film 4 and the upper mold 2 and the lower mold 3, the clamping positions of the upper mold 2 and the lower mold 3 are fastened with bolts or clamps, and the upper mold 2 and the lower mold 3 are covered by the vacuum film 6 The two ends of the vacuum membrane 4 and the vacuum membrane 6 are respectively sealed together, the vacuum membrane 6 is provided with an air extraction hole 8, and the whole mold is put into the autoclave 7, and the autoclave 7 is provided with an air inlet 9. All the air inside the mold is exhausted through the exhaust hole 8 to form a vacuum. After passing the decompression test, the compressed air is input through the air inlet hole 9 to pressurize, and the electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com