Grid stacking structure capable of optimizing performances of composite material laminated plate and production method

A composite material layer and layup technology, applied in the field of composite materials, can solve the problems of weak overall performance of composite material laminates, and achieve the effects of improving interlaminar shear performance, increasing tensile strength, and promoting development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

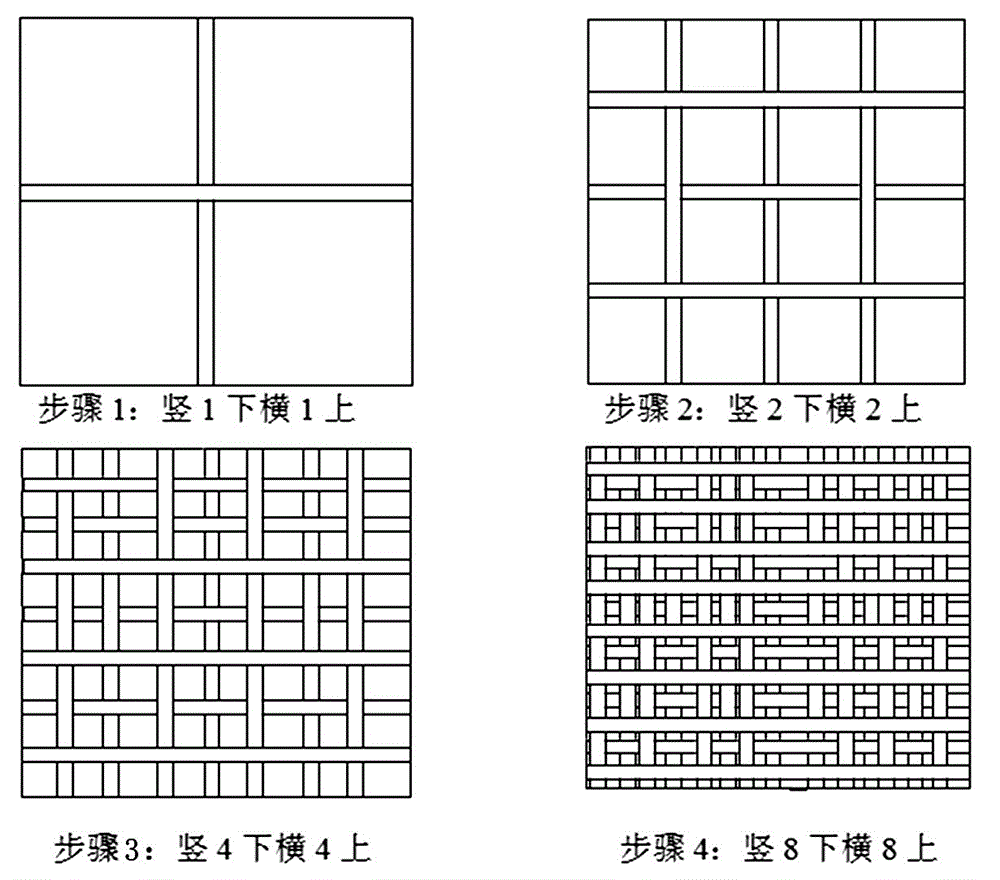

[0024] Such as figure 1 As shown, a method for making a grid lay-up structure for optimizing the performance of composite material laminates is characterized in that it comprises the following steps:

[0025] 1) Set the target lay-up structure size, use a slitting machine to cut the large carbon fiber reinforced resin-based prepreg raw material into rectangular strips of a certain width and roll them up according to the target lay-up structure size. The length is 2 of the width of the rectangular strip m -1 times, the width of the target laminate is 2 times the width of the rectangular strip n -1 times, m, n are non-zero natural numbers, m, n can be equal or unequal, that is, the length and width of the target layer structure can be unequal;

[0026] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com