Halogen-free flame retardant epoxy resin system, prepreg and preparing methods thereof

An epoxy resin system and epoxy resin technology, applied in the field of composite materials, can solve the problems of poor mechanical properties of composite materials, affect the compactness of composite materials, and cannot be used as load-bearing structures, and achieve improved strength and modulus, good toughness, The effect of improving interlaminar shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides a preparation method of a halogen-free flame-retardant epoxy resin system, including:

[0042] (1) Weigh the following components in mass percentage:

[0043] 30-70% of liquid epoxy resin, 5-30% of solid resin, 12-32% of solid halogen-free flame retardant, and 2-8% of epoxy curing agent; the raw materials used in this example are all provided by the above resin system examples, For specific descriptions and effects, refer to the foregoing embodiments, and details are not repeated here.

[0044] (2) mixing the liquid epoxy resin and solid resin to obtain a liquid resin mixture;

[0045] (3) adding the weighed solid halogen-free flame retardant into the liquid resin mixture for reaction, and obtaining a liquid mixed system after the reaction;

[0046] (4) Add the weighed epoxy curing agent into the cooled liquid mixing system and mix to obtain a halogen-free flame-retardant epoxy resin system.

[0047]In an optional...

Embodiment 1

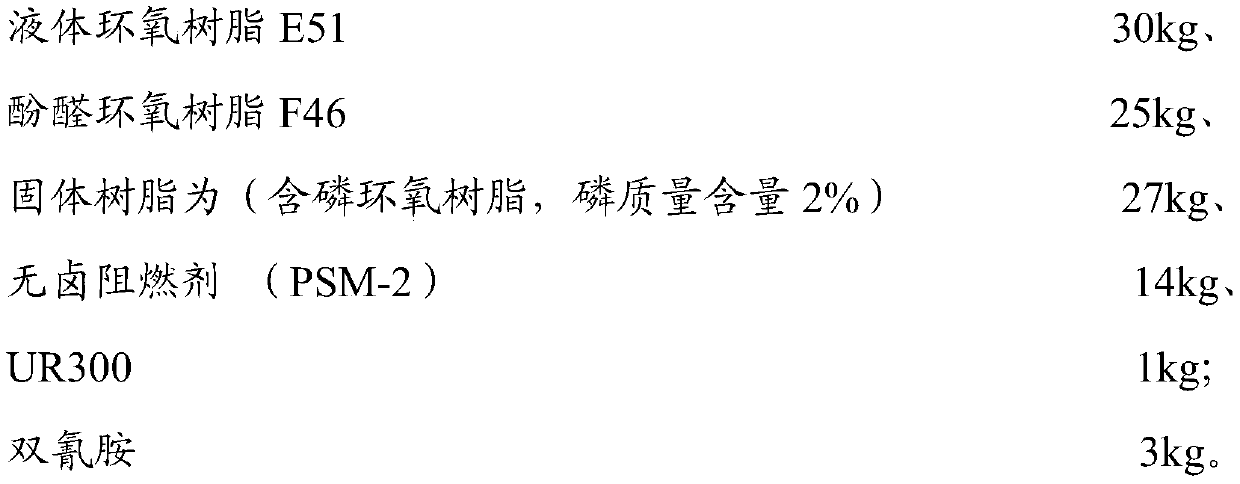

[0069] Weigh raw materials:

[0070]

[0071] Step (1) Raw material pretreatment: baking novolac epoxy resin at 90° C., pulverizing the solid resin to obtain solid resin particles with an equivalent particle diameter of 5 mm or less.

[0072] Step (2) Put the liquid epoxy resin E51 and the baked novolac epoxy resin F46 into a reaction kettle with a temperature control device, add solid resin particles, and stir for 20 minutes at 75°C to obtain a liquid resin mixture .

[0073] Step (3) Add the powdered halogen-free flame retardant to the liquid resin mixture obtained in step (2), heat to a temperature of 80°C, stir and mix, stir for 60 minutes, heat up to 130°C, continue stirring for 120 minutes to obtain a liquid mixture system.

[0074] Step (4) Cool the liquid mixed system obtained in step (3) to 70°C under stirring, add a latent epoxy curing agent, and stir at 70°C for 20 minutes at high speed to obtain a halogen-free flame-retardant epoxy resin system.

[0075] Step...

Embodiment 2

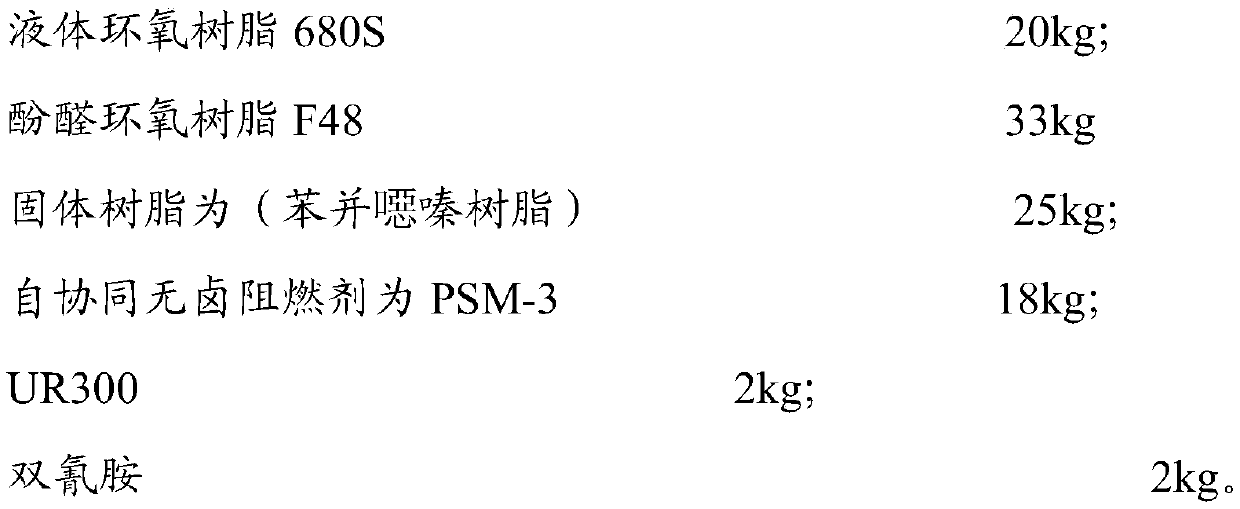

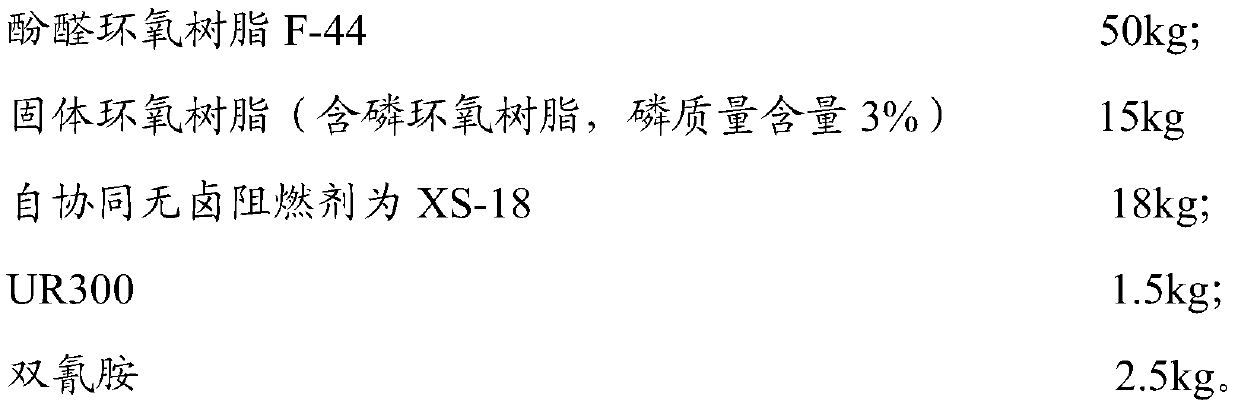

[0081] In the halogen-free flame retardant epoxy resin system: the matrix component containing the following mass percentage content

[0082]

[0083] Step (1) Raw material pretreatment: Baking and melting the novolac epoxy resin F48 at 80° C., crushing the massive solid resin to obtain solid resin particles with an equivalent particle diameter of 3 mm or less.

[0084] Step (2) Put the liquid epoxy resin 680S and the baked novolac epoxy resin F48 into a reaction kettle with a temperature control device, add the solid epoxy resin, and stir for 20 minutes at 80°C to obtain a liquid resin mixture.

[0085] Step (3) Add the powdered halogen-free flame retardant to the liquid resin mixture obtained in step (2), stir and mix, heat up to 70°C, stir for 60 minutes, raise the temperature to 130°C, continue stirring and mixing for 120 minutes, and obtain a liquid mixed system.

[0086] Step (4) Cool the liquid mixed system obtained in step (3) to 60° C. under stirring, add a curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com