Manufacturing method for three-dimensional textile having orthogonal structure and plain weave structure

A three-dimensional machine and fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of insufficient structural tightness, unsatisfactory, easy displacement, etc., achieve compact structure, improve structural tightness, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

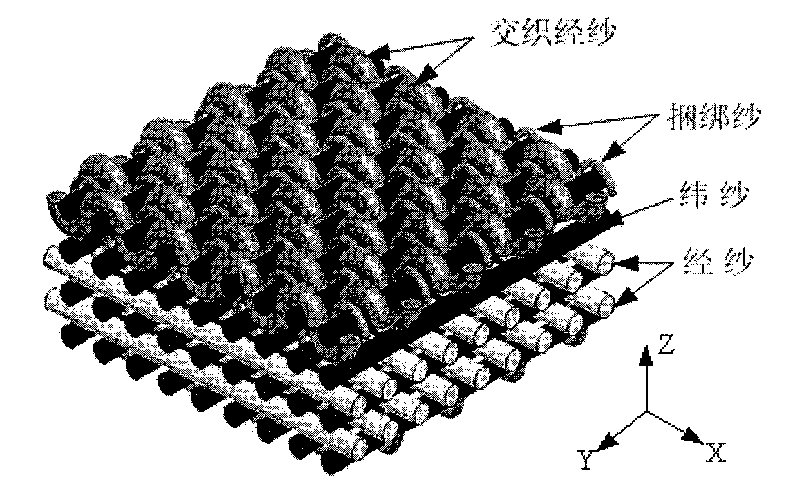

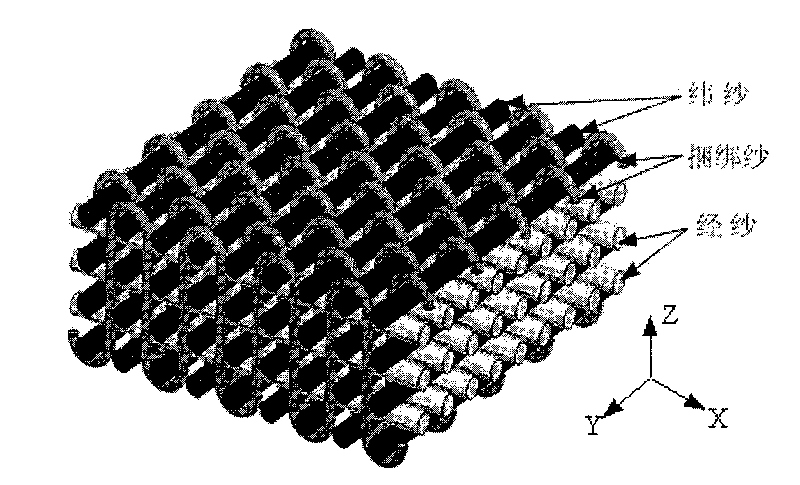

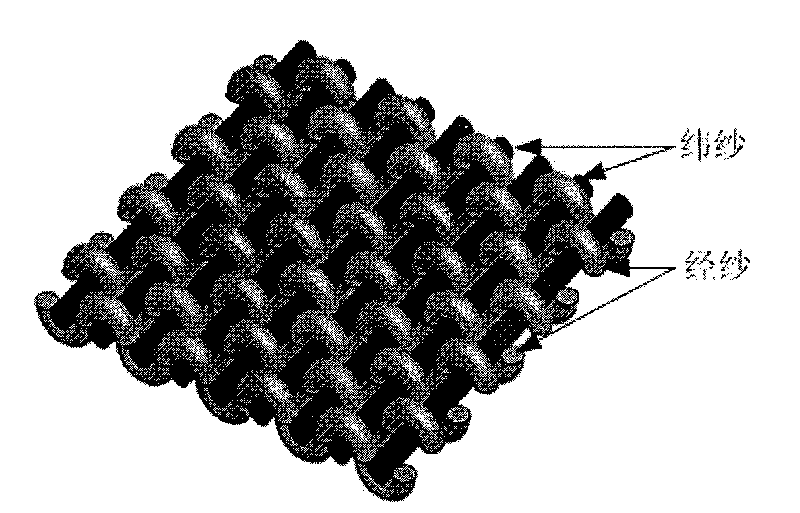

[0031] Design and manufacture a three-dimensional woven composite material with a plain weave structure on the surface and an orthogonal structure on the inner and bottom layers

[0032] 1. There are seven layers of warp and weft yarns in the three-dimensional woven fabric. The warp yarns on the top layer are copper stranded wires, and the warp and weft yarns and binding yarns of the remaining layers are all glass fibers.

[0033] 2. Select the warp and weft yarns of the surface layer of the three-dimensional woven fabric as the plain structure layer, and the other layers as the orthogonal structure layer.

[0034] 3. Weaving three-dimensional woven composite material preforms.

[0035] First, pass the odd-numbered yarns and even-numbered yarns of the first layer of warp yarns (ie copper strands) through the heald holes of the two heald frames respectively. The warp threads of the remaining layers directly pass through the heald frame according to certain rules, without passi...

Embodiment 2

[0040] Embedding structural health detection devices into 3D woven composites

[0041] According to the design requirements, the optical fiber is embedded in the surface layer of the 20cm-long three-dimensional woven composite material with the corresponding curvature

[0042] 1. Design the three-dimensional fabric with seven layers of warp yarns, select glass fiber as the warp and weft yarns and binding yarns of each layer, and select the thickness of the weft yarns according to the curvature requirements of the optical fiber. In this example, the warp and weft yarn density is 2400tex, and the binding yarn is 400tex;

[0043] 2. Weaving 3D woven composite material preforms

[0044] At first, select five layers of warp yarns, 200 in each layer, change the 100th warp yarn in the first layer of warp yarns into optical fibers and pass through the heald holes. The warp threads of the remaining layers directly pass through the heald frame according to certain rules, without passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com