Janus particle/epoxy resin composite material

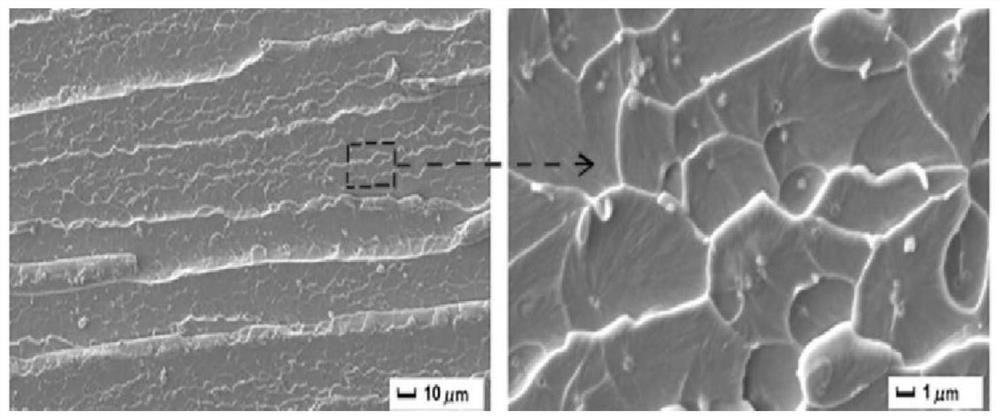

A technology of epoxy resin and composite materials, which is applied in the field of Janus materials, can solve the problems affecting the performance of the matrix, achieve the effects of improving the toughness of the matrix, preventing the development of cracks, and improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

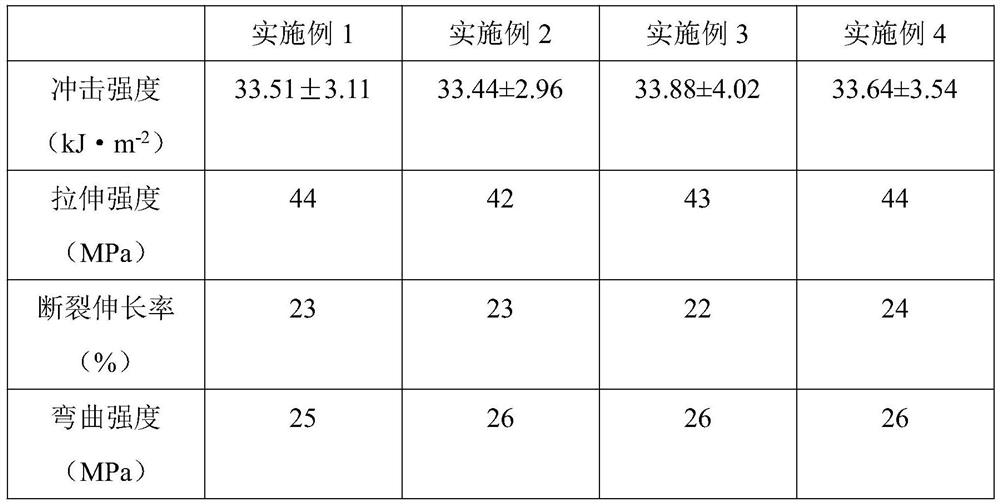

Embodiment 1

[0025] A kind of Janus particle / epoxy resin composite material, specifically comprises the steps:

[0026] S1: Add polystyrene and polydivinylbenzene mixed powder with a mass ratio of 0.36:0.64 into deionized water, wherein the mass volume ratio of the mixed powder to deionized water is 1g:15mL, and then add aluminum oxide, Wherein the mass ratio of polydivinylbenzene and aluminum oxide is 1:0.24, ultrasonic dispersion, then add azobisisobutyronitrile, wherein the mass ratio of azobisisobutyronitrile and polydivinylbenzene is 1: 100, after ultrasonic stirring for 3 hours, prepare for the next step.

[0027] S2: adding the mixture in step S1 to a 5% sodium dodecylbenzenesulfonate aqueous solution, wherein the volume ratio of the mixture to the sodium dodecylbenzenesulfonate aqueous solution is 1g:4mL, ultrasonically dispersed, Then add γ-methacryloxypropyl trimethoxysilane, wherein the mass ratio of the mixture and γ-methacryloxypropyltrimethoxysilane is 1:0.3, and then dropwi...

Embodiment 2

[0030] A kind of Janus particle / epoxy resin composite material, specifically comprises the steps:

[0031] S1: Add the mixed powder of polystyrene and polydivinylbenzene with a mass ratio of 0.44:0.72 to deionized water, wherein the mass volume ratio of the mixed powder to deionized water is 1g:20mL, and then add aluminum oxide, wherein The mass ratio of polydivinylbenzene and aluminum oxide is 1:0.32, ultrasonic dispersion, and then add azobisisobutyronitrile, wherein the mass ratio of azobisisobutyronitrile and polydivinylbenzene is 1:120 , after ultrasonic stirring for 3 h, it was prepared for use in the next step.

[0032] S2: adding the mixture in step S1 to an aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 8%, wherein the volume ratio of the mixture to the aqueous solution of sodium dodecylbenzenesulfonate is 1g:7mL, ultrasonically dispersed, Then add γ-methacryloxypropyl trimethoxysilane, wherein the mass ratio of the mixture to γ-methacrylo...

Embodiment 3

[0035] A kind of Janus particle / epoxy resin composite material, specifically comprises the steps:

[0036] S1: Add the mixed powder of polystyrene and polydivinylbenzene with a mass ratio of 0.4:0.68 to deionized water, wherein the mass volume ratio of the mixed powder to deionized water is 1g:16mL, and then add aluminum oxide, wherein The mass ratio of polydivinylbenzene and aluminum oxide is 1:0.28, ultrasonic dispersion, and then add azobisisobutyronitrile, wherein the mass ratio of azobisisobutyronitrile and polydivinylbenzene is 1:110 , after ultrasonic stirring for 3 h, it was prepared for use in the next step.

[0037] S2: Add the mixture in step S1 to a 6% sodium dodecylbenzenesulfonate aqueous solution, wherein the volume ratio of the mixture to the sodium dodecylbenzenesulfonate aqueous solution is 1g:5mL, ultrasonically disperse, Then add γ-methacryloxypropyl trimethoxysilane, wherein the mass ratio of the mixture to γ-methacryloxypropyltrimethoxysilane is 1:0.33, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com