Basalt fiber and carbon fiber hybrid composite compressed natural gas cylinder and preparation method thereof

A technology of basalt fiber and compressed natural gas, which is applied in the direction of mechanical equipment, pressure vessels, fixed-capacity gas storage tanks, etc., can solve the problems affecting the usability of carbon fiber-wound aluminum alloy gas cylinders, the decrease in strength of composite materials, and poor interlayer shear performance, etc. Problems, to achieve good resistance to heat and humidity, low production costs, to ensure the effect of pressure-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

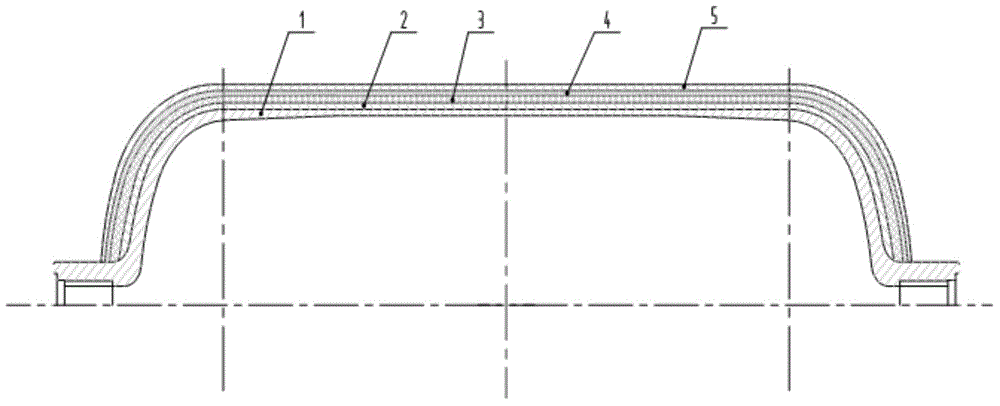

Image

Examples

Embodiment 1

[0027] Wet winding process is used to prepare 100L basalt fiber and carbon fiber hybrid composite compressed natural gas cylinder with a working pressure of 35MPa. The winding tension of basalt fiber is 20-16N, the tension of carbon fiber is 30-23N, and the tension of glass fiber is 18-15N. .

[0028] Main raw materials: EPIKOTE 828 epoxy resin, basalt fiber treated with KH-550 silane coupling agent with a linear density of 1200tex and a tensile strength of 3800MPa, SYT49-12K carbon fiber with a tensile strength of 5012MPa and 2800MPa tensile strength ERC-550 glass fiber treated with UP-570 coupling agent;

[0029] The epoxy resin matrix, basalt fiber, carbon fiber and glass fiber are combined into a pressure vessel product through process equipment, process technology and structural design, including coating of interlayer bonding coordination layer, winding of basalt fiber composite layer, winding of carbon fiber composite layer The glass fiber composite layer is wound and t...

Embodiment 2

[0043] Adopt the raw material identical with embodiment 1 to prepare:

[0044] Step 1. Interlayer bonding coordination layer coating

[0045] Install the aluminum alloy lining on the fixed bracket that rotates 360° every 15 seconds, and use a brush to dip in the white high-solid acrylic polyurethane water-based paint to coat to ensure that the outer surface of the aluminum liner is completely coated and evenly coated. The layer thickness is 0.2mm;

[0046] Step 2. Basalt fiber composite layer winding

[0047] Prepare epoxy resin matrix glue, the specific mass ratio of each component is: EPIKOTE 828 epoxy resin: C352350 multi-walled carbon nanotubes: methyl tetrahydrophthalic anhydride curing agent: methyl hexahydrophthalic anhydride accelerator: AFE-1520 silicone Ketone defoamer=100:9:80:3:2, stir evenly to ensure uniform mixing of all components.

[0048] The basalt fiber composite layer is wound by wet winding process, according to 89 2 / 45 2 / 89 2 The winding sequence...

Embodiment 3

[0057] The difference from Example 1 is that the proportion of the epoxy resin matrix glue solution prepared in step 2 is different:

[0058] The mass ratio of each component is, EPIKOTE 828 epoxy resin: C352350 multi-walled carbon nanotubes: methyl tetrahydrophthalic anhydride curing agent: methyl hexahydrophthalic anhydride accelerator: AFE-1520 organic silicone defoamer = 100:10: 80:1:1.

[0059] The water pressure blasting test and the drop test were carried out to verify this embodiment, and the experimental results show that the hybrid compressed natural gas cylinder prepared by this method has good pressure bearing effect and impact resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com