Method for optimizing interface of basalt reinforced resin-based composite material

A technology for reinforcing resin-based and composite materials, applied in the field of basalt fiber composite materials, can solve problems such as poor interface compatibility and unsatisfactory bonding effect, achieve low thermal conductivity, enhance mechanical meshing and chemical bonding, and improve roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

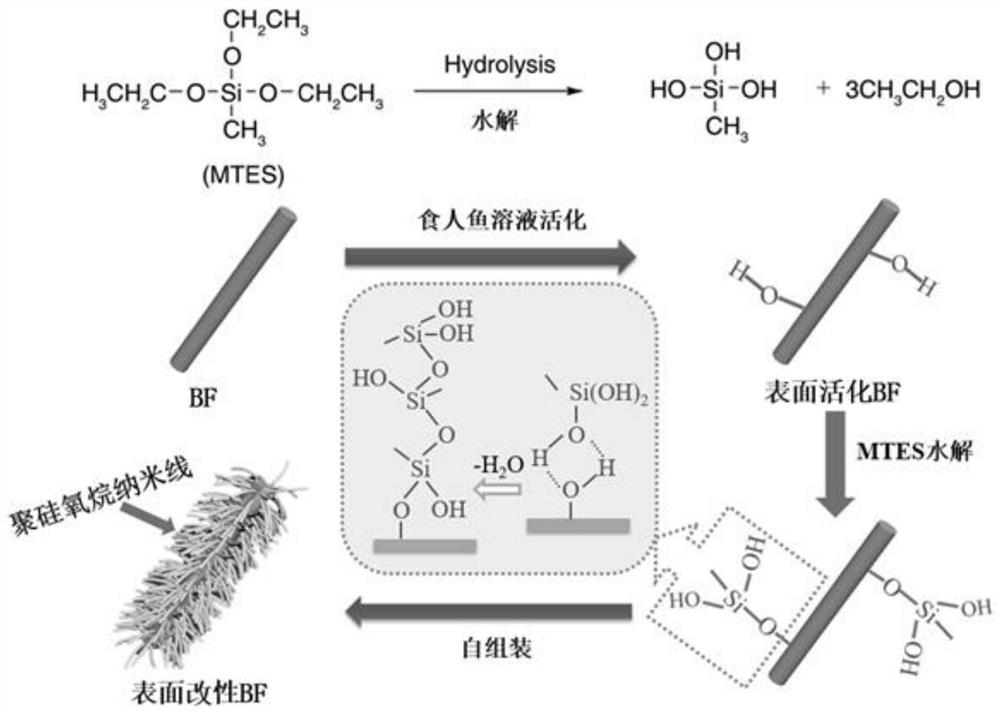

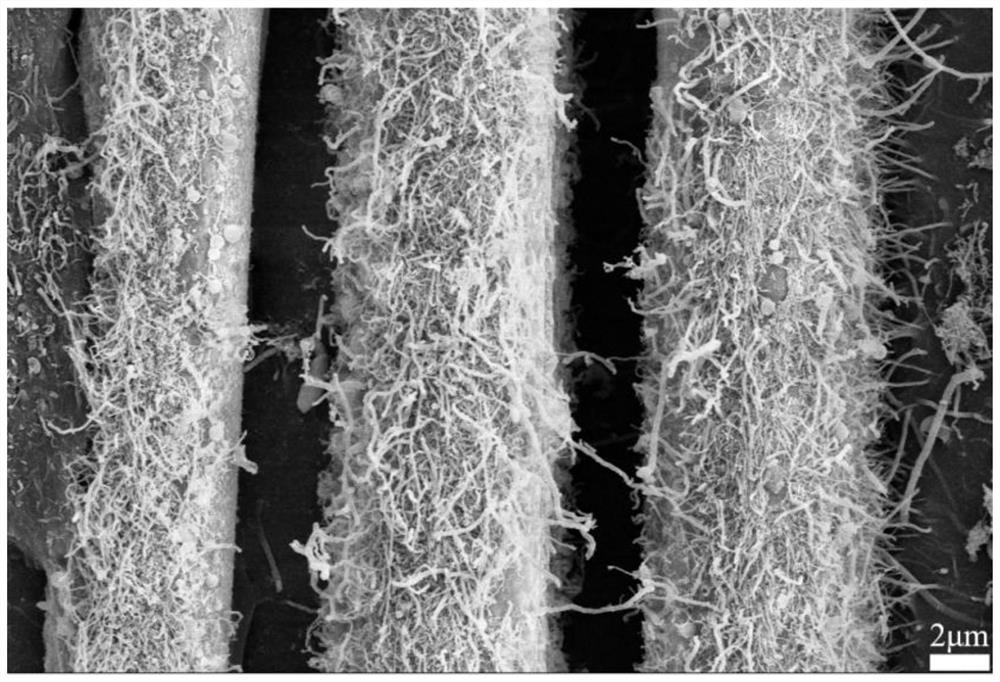

[0024] The method for interface optimization of basalt-reinforced resin-based composite material provided by the present invention, the steps are as follows:

[0025] (1) Heat the basalt fiber in a mixed solution of acetone and petroleum ether at a volume ratio of 2:1 to reflux at 60°C for 6 hours, wash it with plasma water for 3 to 4 times, and then put the basalt fiber into a vacuum oven to dry at 80°C After 12 hours, the basalt fiber after surface desizing was obtained. (2) Hydrogen peroxide (mass percentage concentration 30%, AR) and concentrated sulfuric acid are formulated into a piranha solution (piranha solution) according to a volume ratio of 7:3 as an activation solution, and hydrogen peroxide should be added to concentrated sulfuric acid during preparation . Immerse the basalt fiber after surface cleaning and desizing into the prepared activation solution, raise the temperature to 90°C and soak for 30 minutes, then wash it with a large amount of plasma water for 2-...

Embodiment 2

[0029] On the basis of embodiment 1, in the change step (3), the reaction time is 4h, and other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com