Positive electrode material with low internal resistance for solid state lithium battery and preparation method of positive electrode material

A technology of cathode materials and cathode active materials, applied in the field of lithium-ion battery preparation, can solve problems such as difficulty in achieving uniform coating of lithium conductive oxides and carbon materials, destruction of lithium ion and electron transport channels, lack of flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

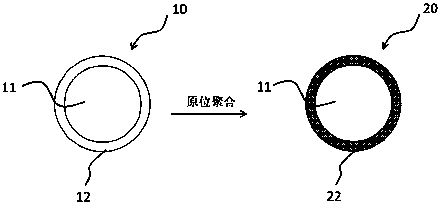

Method used

Image

Examples

Embodiment 1

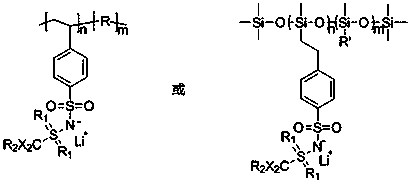

[0040] First, add 1.0 g of carbon nanotubes and 80.0 g of lithium cobaltate powder into 20 ml of N,N-dimethylformamide and stir evenly, then add 5.0 g of (p-vinylbenzenesulfonyl) trifluoromethanesulfonimide Stir lithium and 5.5 g maleic anhydride evenly, then add 0.02 g azobisisobutyronitrile, in situ polymerization at 70 °C for 20 h, and wash with tetrahydrofuran to obtain carbon nanotubes and poly((paraethylene phenylsulfonyl) trifluoromethanesulfonimide lithium-maleic anhydride) composite material coated lithium cobalt oxide cathode material, wherein the thickness of the surface composite material layer is about 10 nm.

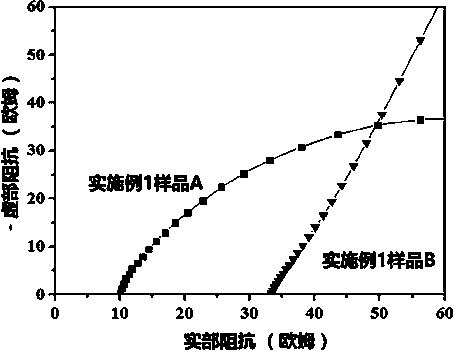

[0041] Using the lithium cobaltate positive electrode material coated with carbon nanotubes and poly((p-vinylbenzenesulfonyl)trifluoromethanesulfonimide lithium-maleic anhydride) composite material prepared in this example, according to the positive electrode material: poly The mass ratio of vinylidene fluoride = 90:10 is used to prepare the positive electr...

Embodiment 2

[0043] First, add 0.5 g of carbon nanofibers and 50.0 g of lithium iron borate powder into 20 ml of N,N-dimethylformamide and stir well, then add 2.0 g of (p-vinylbenzenesulfonyl) trifluoromethanesulfonimide Stir lithium and 2.1 g methyl acrylate evenly, then add 0.02 g azobisisobutyronitrile, complete polymerization at 60 °C, and wash with tetrahydrofuran to obtain carbon nanofibers and poly((p-vinylbenzenesulfonyl) Lithium iron borate cathode material covered by in-situ polymerization of trifluoromethanesulfonyl imide-methyl acrylate) composite material, in which the thickness of the surface composite material layer is about 25 nm.

Embodiment 3

[0045] First, add 0.5 g of graphite, 20.0 g of lithium cobaltate, and 30.0 g of nickel-cobalt-lithium manganese oxide powder into 50 ml of acetonitrile and stir evenly, then add 1.0 g of polymethylhydrogensiloxane, 2.0 g of (2-methoxyethoxy Base) ethylene and 1.5 g (p-vinylbenzenesulfonyl) lithium trifluoromethanesulfonimide were stirred evenly, then 0.05 g benzoyl peroxide was added, and the polymerization reaction was completed at 80 °C, washed with n-hexane, and then Lithium cobalt oxide and lithium nickel cobalt lithium manganese oxide cathode materials coated with graphite and functionalized poly(methylsiloxane) composite materials in situ were obtained, wherein the thickness of the surface composite material layer was about 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com