Method for brazed joint of metal workpieces

A technology for metal workpieces and workpieces, applied in the field of brazing metal workpieces, can solve the problems of increasing the manufacturing steps of heat exchangers, increasing the steps of cleaning workpieces, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

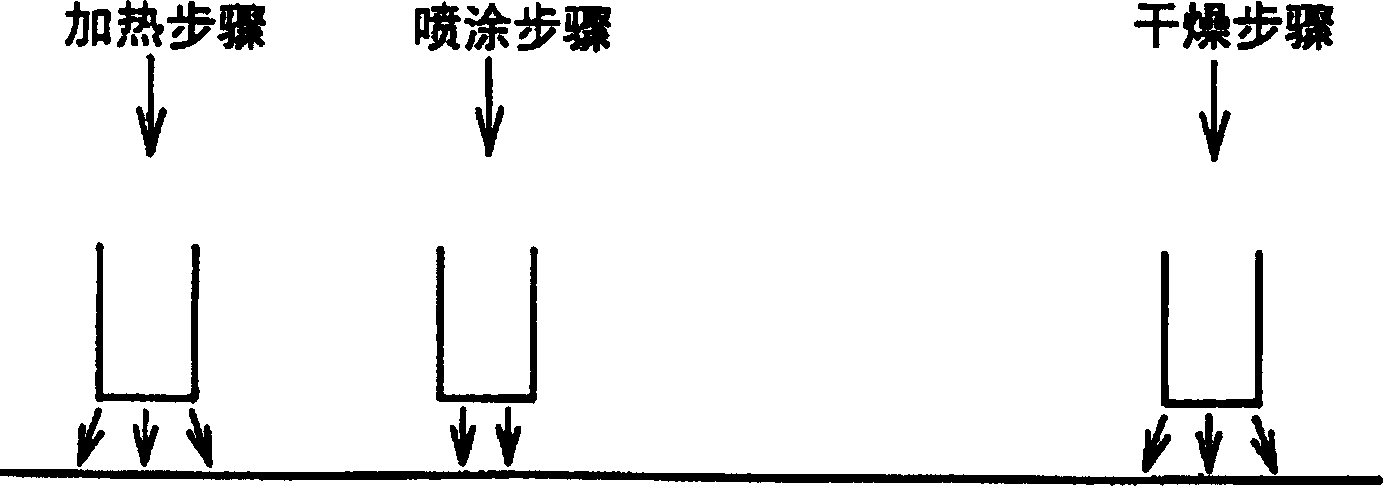

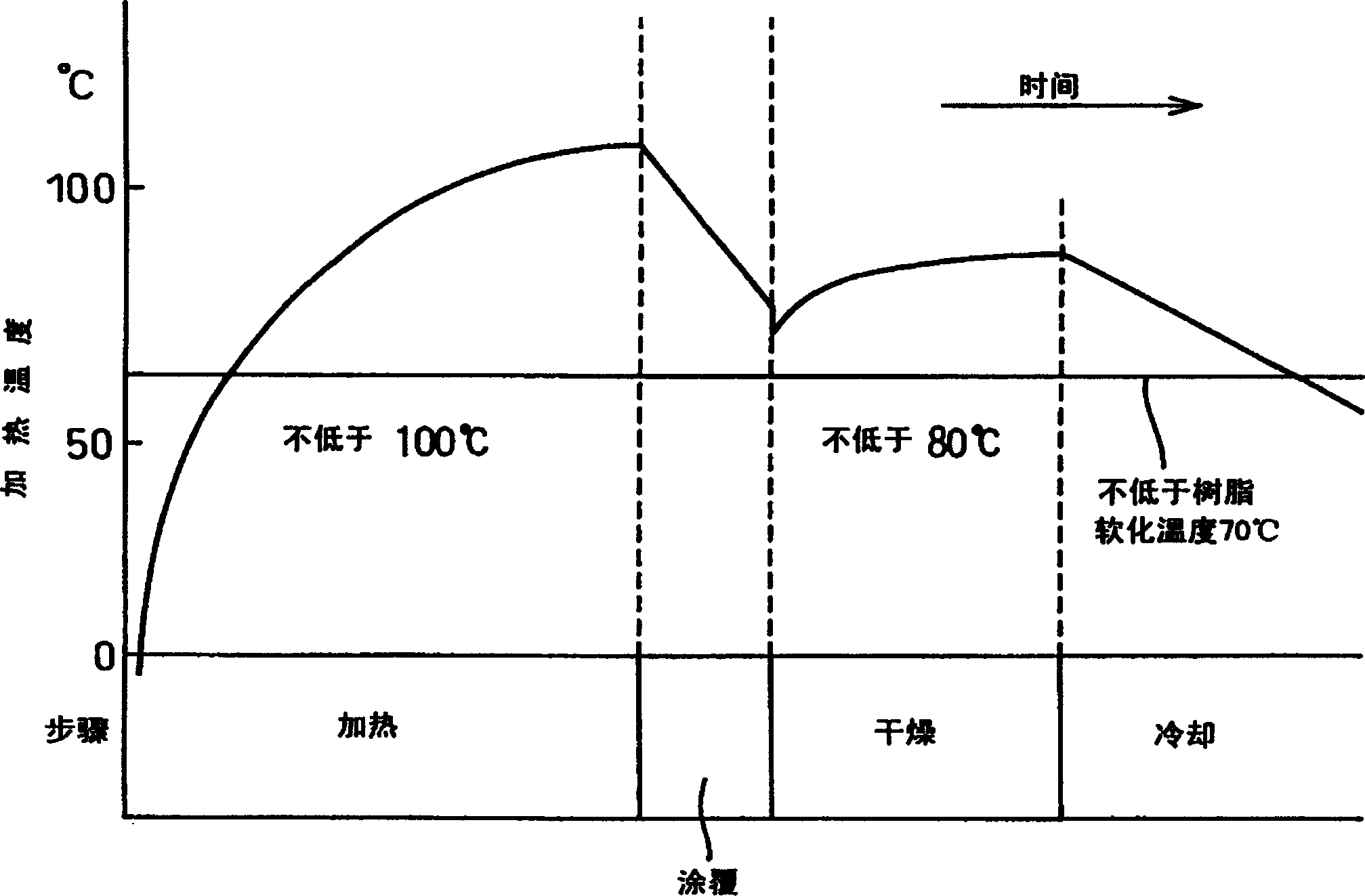

[0037] The brazing method of the first embodiment of the present invention is used to manufacture automobile radiators.

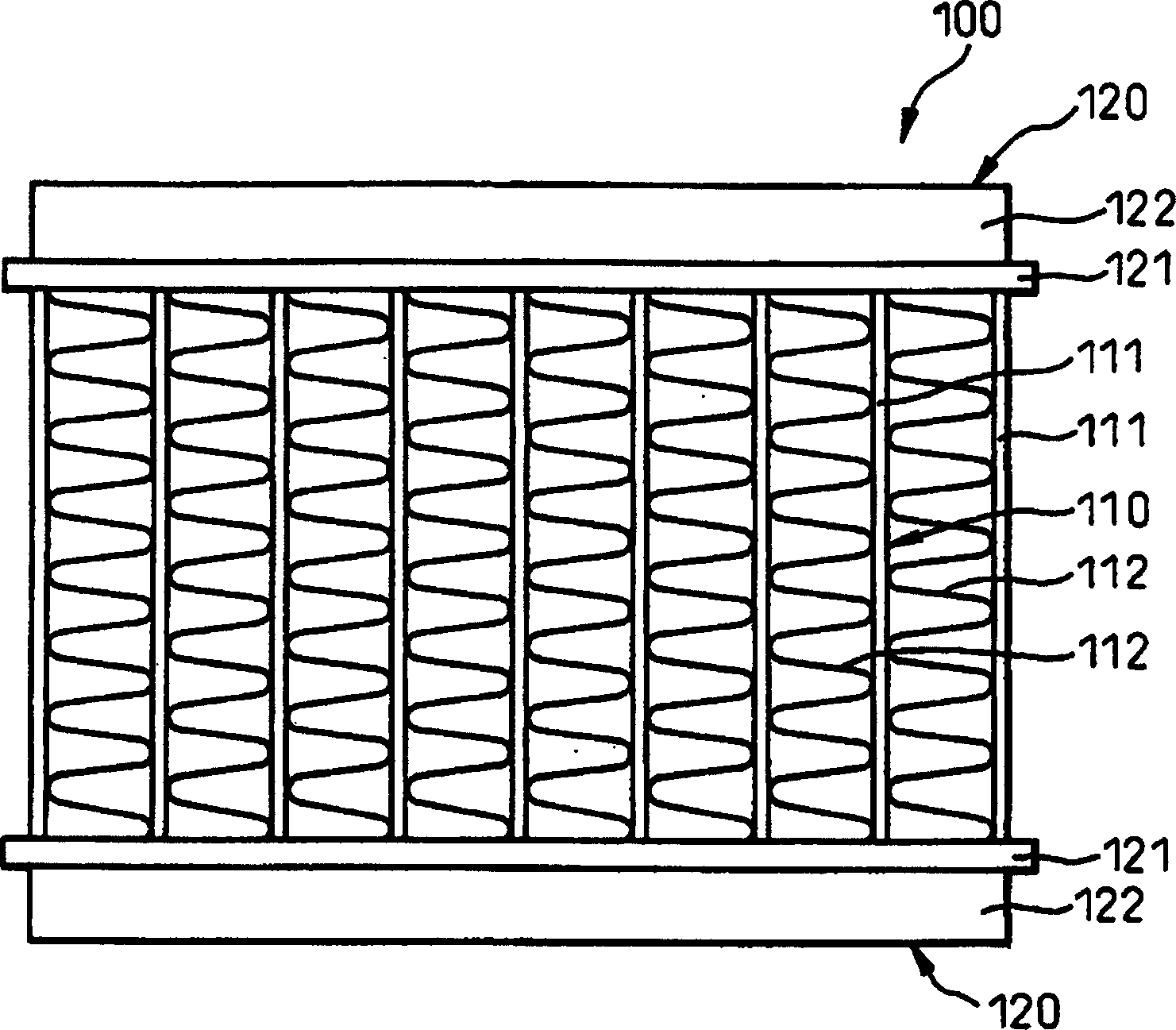

[0038] like figure 1 As shown, the radiator 100 is composed of a core 110 and an end tank 120. The core 110 includes a plurality of tubes 111 through which cooling water passes and a plurality of tubes arranged between the tubes 111 to promote heat exchange between the cooling water and air. Corrugated fins 112 , end tanks 120 are provided at both longitudinal ends of the tubes 111 and communicate with each tube 111 .

[0039] The end water tank 120 is composed of a core plate 121 and a water tank body 122, the pipe 111 is inserted into the core plate 121, and the water tank body 122 and the core plate 121 together form an inner water holding space. According to this embodiment, the tube 111, the fins 112, and the core plate 121 are made of aluminum alloy, and the tank body 122 is made of resin.

[0040] The tube 111, the fin 112 and the core plate 121 ar...

no. 2 example

[0054] Unlike the first embodiment in which the suspension is applied by spraying (spraying) the suspension onto the workpiece from a nozzle, in Figure 5 In the illustrated embodiment, the coating step is carried out by a trickle method which releases suspended droplets to the workpiece.

no. 3 example

[0056] Different from the foregoing embodiments in which the heating step is performed by blowing hot air to the workpiece (hereinafter referred to as the hot air heating method), in the Image 6 In the illustrated embodiment, the heating step is performed by heating the workpiece in a heating furnace (hereinafter referred to as furnace heating method), and the coating step is performed by spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com