Surface coating method and device for exterior part

A technology for surface coating and external parts, applied in the field of surface coating methods and surface coating devices, can solve problems such as difficulty in forming a coating with uniform thickness, inability to spread uniformly, and differences in coating quality, and achieve easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the following description, although the same elements are shown in different drawings, the same elements will be denoted by the same reference numerals (suggested translation: the same elements will be represented by denoted by the same designation). Also, in the following description of the present invention, detailed descriptions of well-known functions and constructions included herein will be omitted when they do not necessarily obscure the subject matter of the present invention.

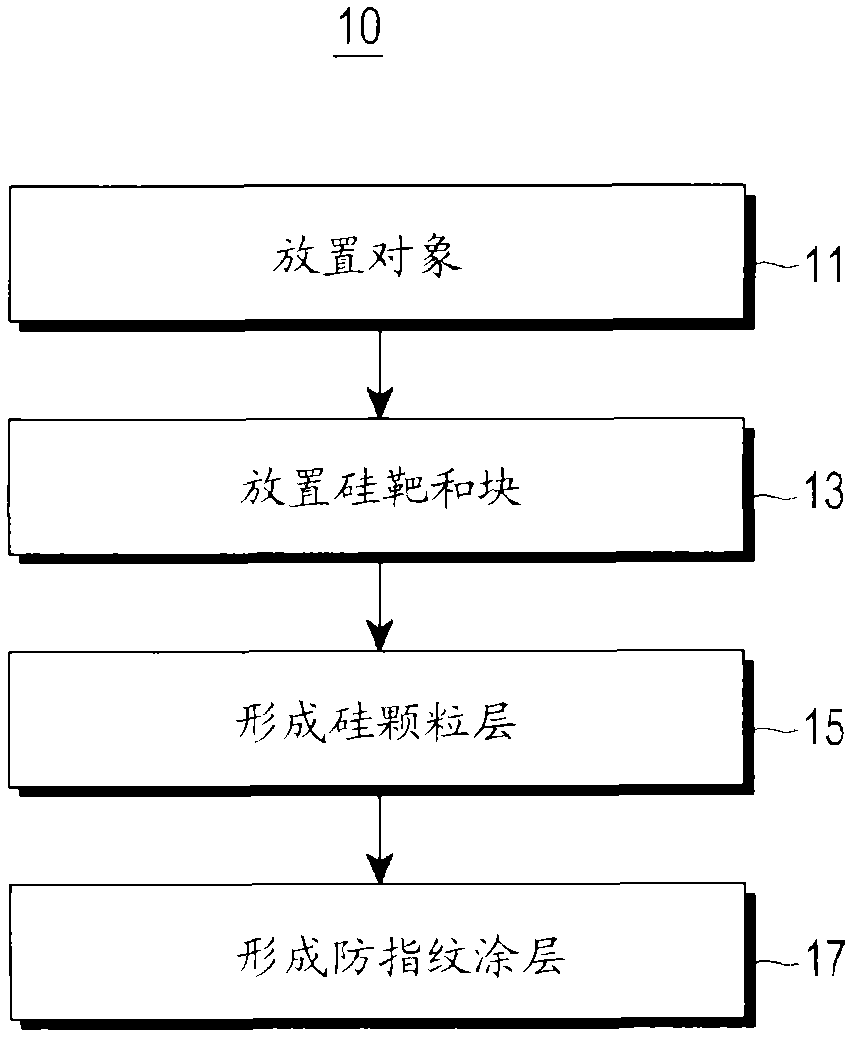

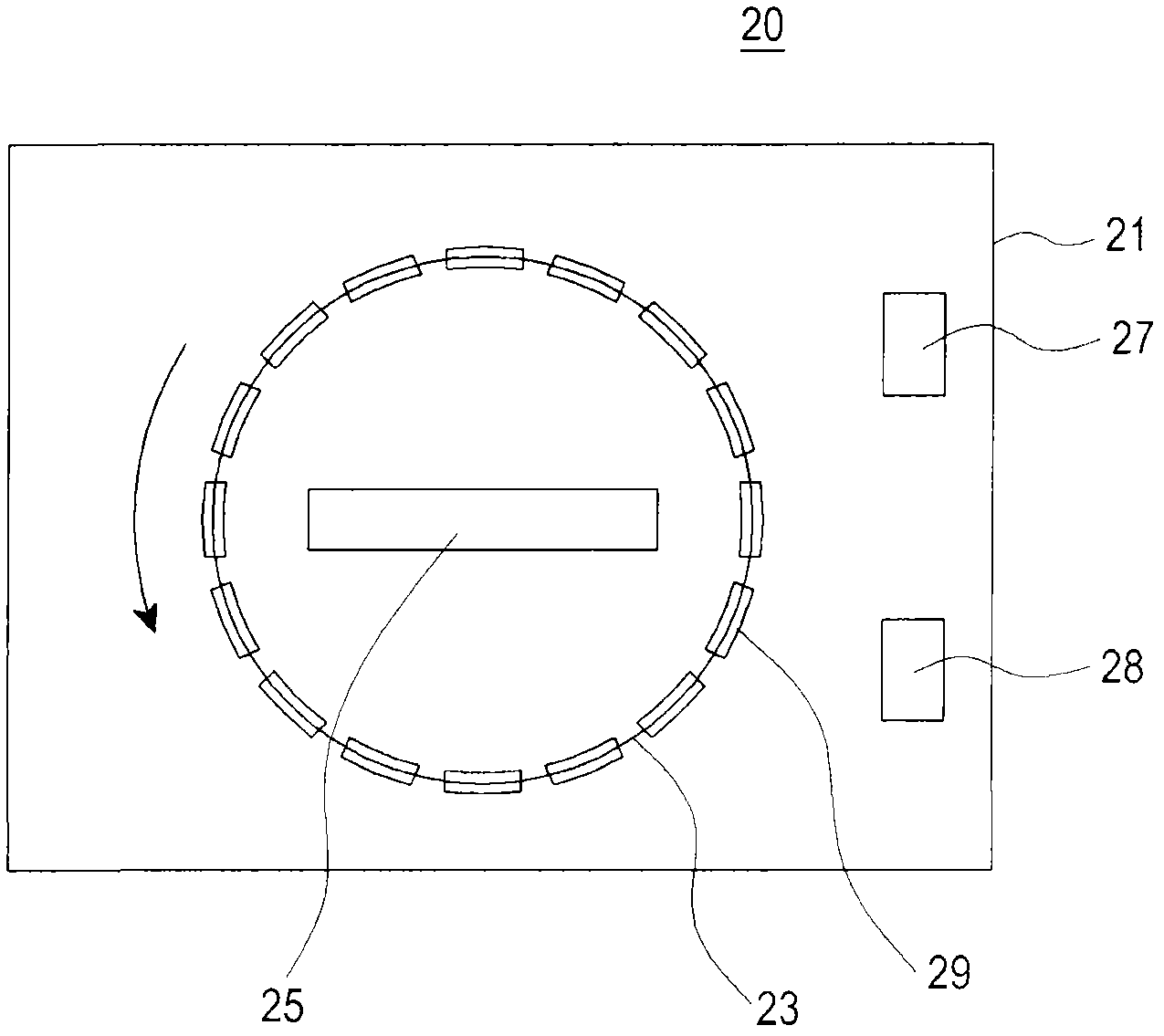

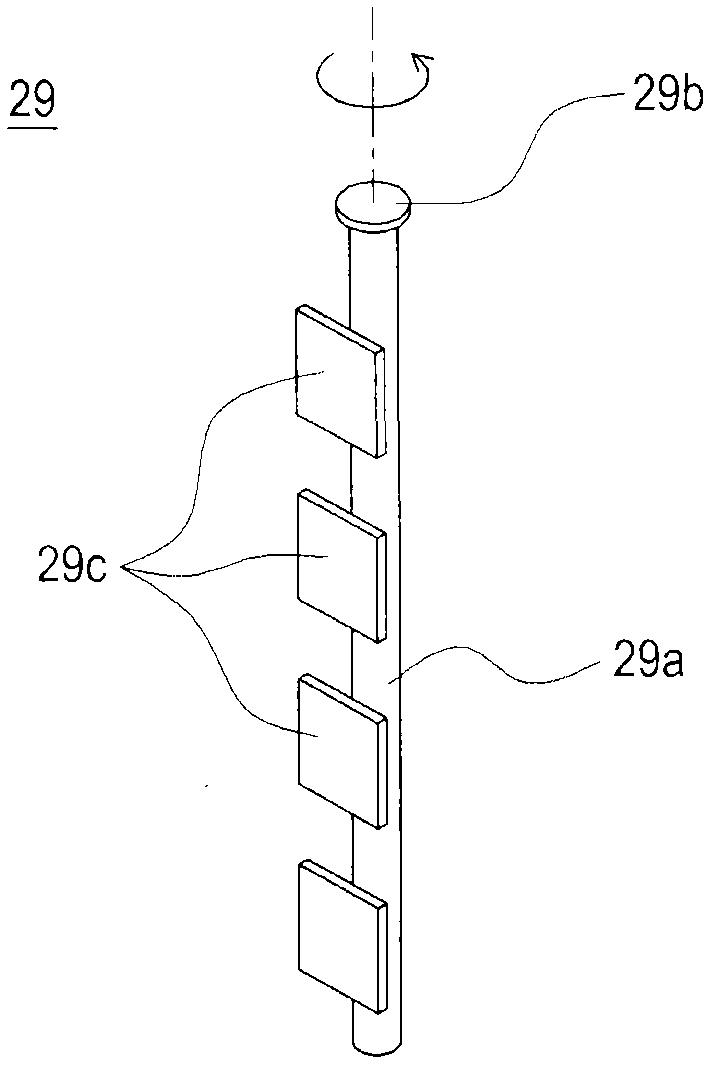

[0019] Such as figure 1 As shown in , the surface coating method 10 for surface coating external parts according to an embodiment of the present invention includes: in step 11 (hereinafter, this step will be referred to as "the first placement step"), in the deposition chamber 21 Place one or more objects 29c to be coated (see image 3 ); in step 13 (hereinafter, this st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com