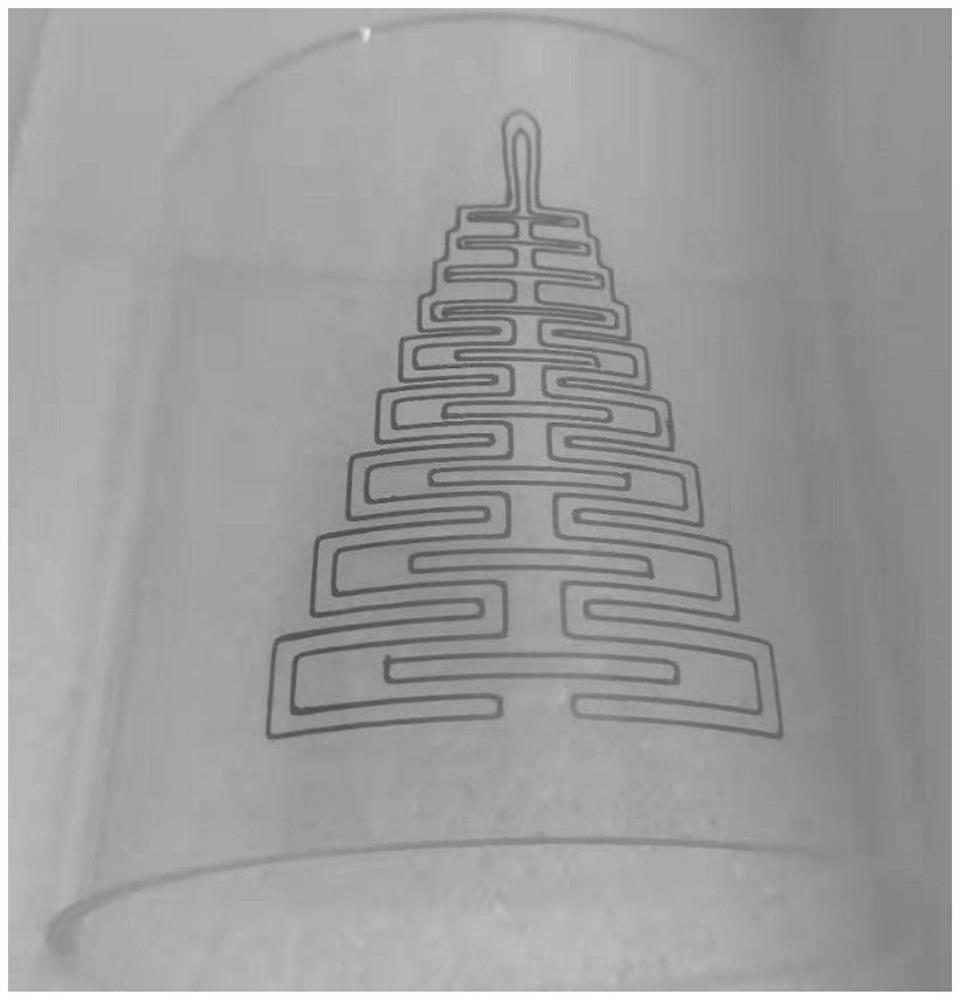

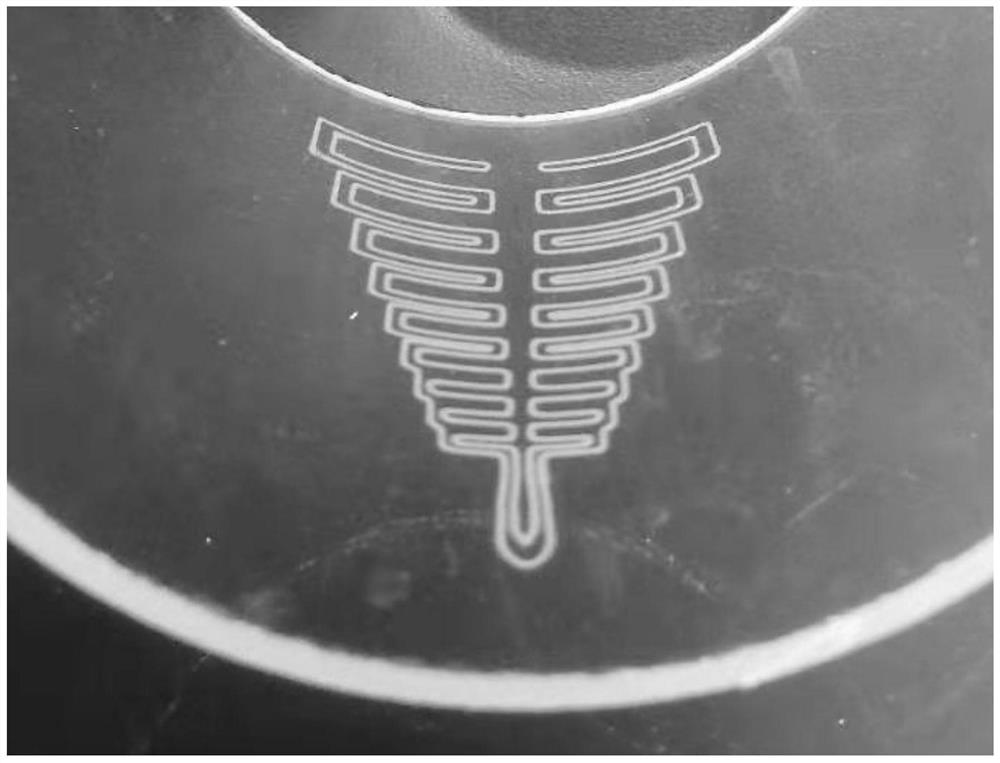

Laser-assisted conformal 3D printing method for complex curved surface special-shaped structure

A complex curved surface, laser-assisted technology, applied in the improvement of process efficiency, additive manufacturing, transportation and packaging, etc., can solve the problems of low printing line width accuracy, difficult to achieve conformal manufacturing of complex non-expanded surface structure surface, etc., to achieve printing High precision, avoiding the effect of forming complex curved surface structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] Specific Embodiment 1: In this embodiment, a laser-assisted method for conformal 3D printing of complex curved surfaces and special-shaped structures is carried out according to the following steps:

[0044] 1. Weighing:

[0045] Weigh 0.5 to 4 parts of photoinitiator, 0.5 to 4 parts of photosensitive resin monomer, 1 to 6 parts of binder, 0.5 to 5 parts of dispersant, and 50 to 85 parts of materials to be printed in parts by mass And 1 to 5 parts of solvent;

[0046] 2. Preparation of laser curing slurry:

[0047] Mix 0.5-4 parts of photoinitiator, 0.5-4 parts of photosensitive resin monomer, 1-5 parts of solvent, 1-6 parts of binder and 0.5-5 parts of dispersant to obtain photosensitive system materials, Then add the photosensitive system material to 50-85 parts of the material to be printed, and use a vacuum defoaming mixer to disperse evenly to obtain a laser-cured slurry;

[0048] 3. Coating:

[0049] Apply the laser-cured slurry evenly on the curved substrate,...

specific Embodiment approach 2

[0061]Specific embodiment two: the difference between this embodiment and specific embodiment one is that the photoinitiator described in step one is 2-hydroxyl-2-methyl-1-phenylacetone, 1-hydroxycyclohexylphenylmethanone Ketone, 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone, 2,4,6-trimethylbenzoyl-diphenyl phosphine oxide or ethyl 2,4,6-trimethylbenzoylphenyl phosphonate; the photosensitive resin monomer described in step one is acrylate; the solvent described in step one is ethyl acetate, acetic acid butyl ester or terpineol; the binder described in step one is polyvinyl butyral or ethyl cellulose; the dispersant described in step one is N-vinylpyrrolidone. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0062] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the material to be printed in step 1 is a mixture of one or both of ceramic powder and metal powder; The ceramic powder is one of silicon oxide, aluminum oxide, silicon nitride, calcium oxide, boron nitride and zirconia or a mixture of several of them; the metal powder is gold, silver, copper and tungsten one or a mixture of several of them. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com