Slurry coating device for battery pole piece in new energy battery production

A technology for battery pole pieces and coating devices, which is applied to battery electrodes, electrode collector coatings, and devices for coating liquid on the surface, etc., which can solve the problem of poor quality of coated pole pieces and affecting coating efficiency. Troubleshooting problems such as cumbersome operation to achieve the effect of preventing uneven slurry, saving preparation time and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

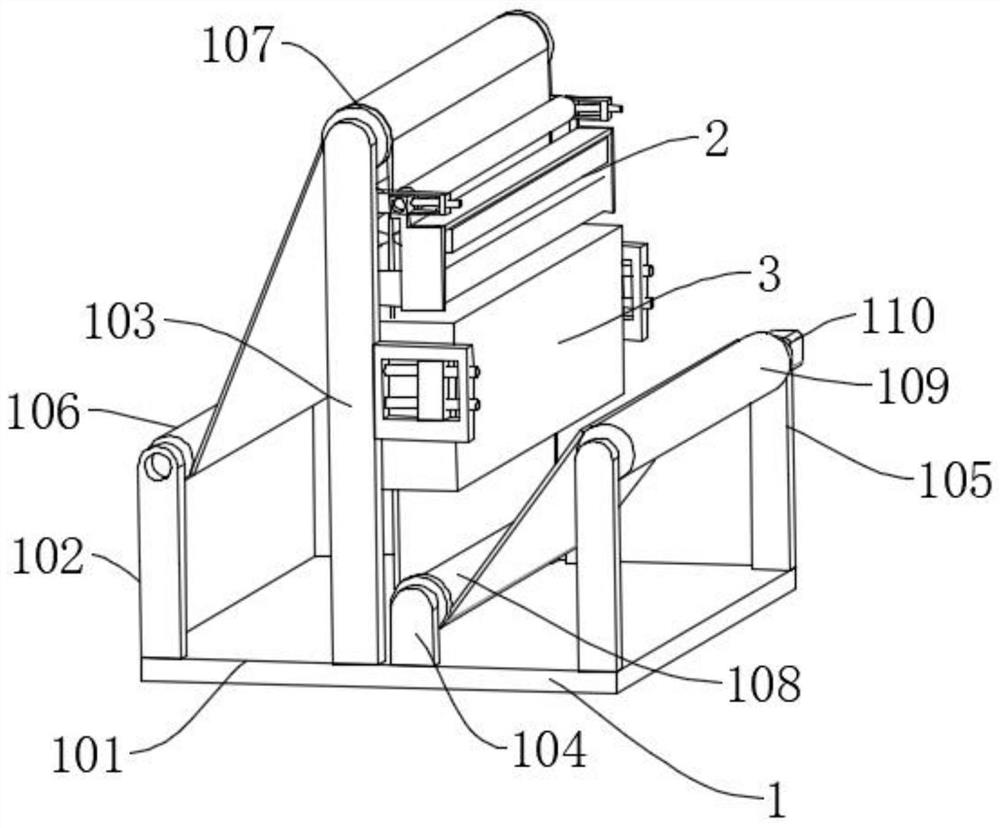

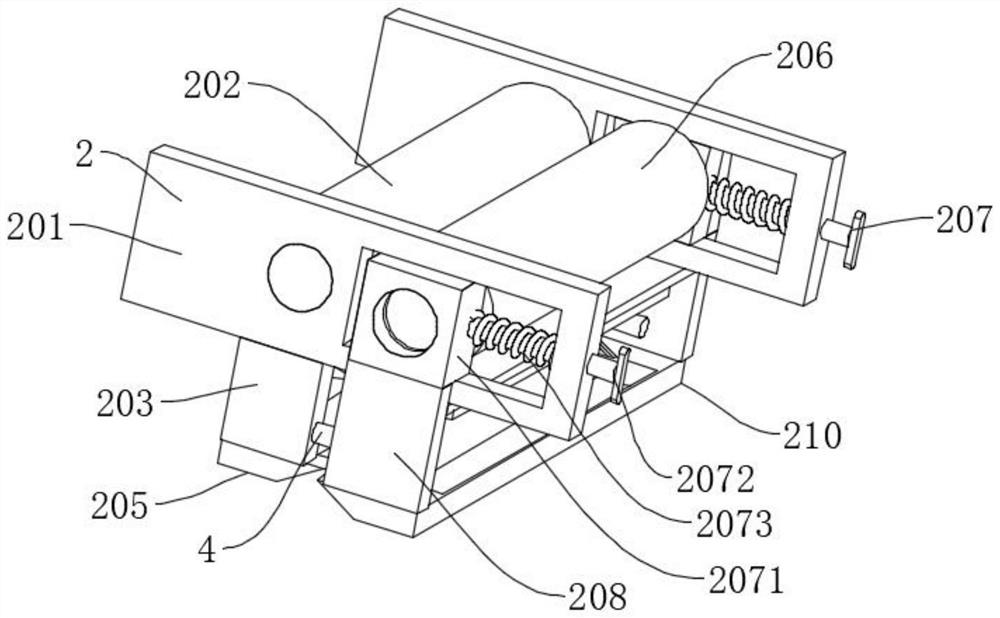

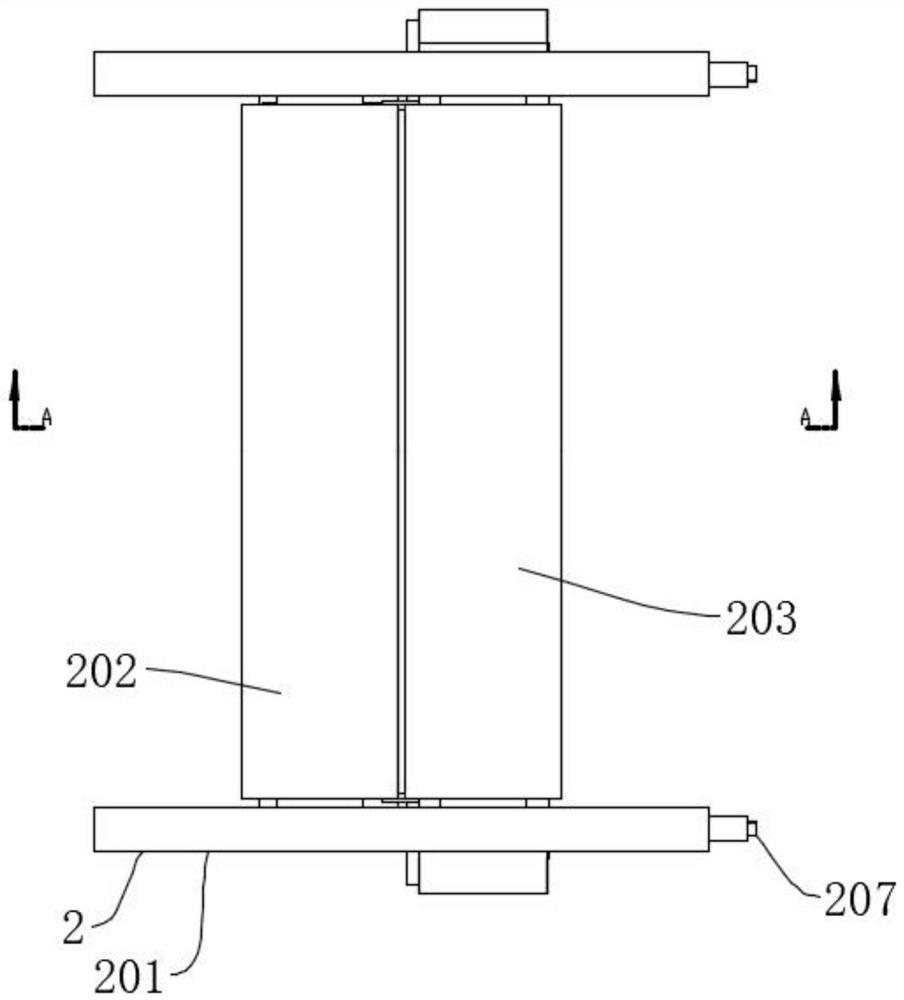

[0033] Such as Figure 1-7 As shown, a battery pole piece slurry coating device for new energy battery production includes a transmission mechanism 1. The transmission mechanism 1 is mainly composed of a bottom plate 101, a first vertical plate 102, a second vertical plate 103, a third vertical plate 104, The fourth vertical plate 105, the discharge roller 106, the first positioning roller 107, the second positioning roller 108, the winding roller 109, and the winding motor 110 are composed of the top of the bottom plate 101 from one side to the other. One vertical board 102, the second vertical board 103, the third vertical board 104, the fourth vertical board 105, the top between the first vertical boards 102 is connected with the discharge roller 106 through the bearing, and the top between the second vertical boards 103 is passed through the bearing The first positioning roller 107 is connected, the top between the third vertical plates 104 is connected with the second pos...

Embodiment 2

[0036] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the second drive assembly 303 includes a slide rail 3031, a second slide block 3035, and a driving cylinder 31, and the slide rail 3031 is connected to the second vertical plate 103 away from the first One side of the vertical plate 102, the inner side of the slide rail 3031 is provided with a second slide block 3035, and the second slide block 3035 is fixedly connected with the moving box body 302, and the end of the second slide block 3035 away from the second vertical plate 103 is connected to the The output end of the driving cylinder 31, and the fixed end of the driving cylinder 31 is fixedly connected with the slide rail 3031, so that the driving cylinder 31 can drive the second slider 3035 to move, and the second slider 3035 can drive the moving box 302 to move, thus realizing The mobile box 302 and the fixed box 301 are separated and assembled.

[0037] In the above structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com