Coating equipment for cylinder mould and coating process applying equipment

A rotary screen and coating technology, applied in the printing process, screen printing, screen printing machine and other directions, can solve the problems of uneven distribution of the surface of the grey fabric, affecting the use of products, uneven coating, etc., and achieve volume increase. , the effect of reducing the amount of use, good antistatic and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

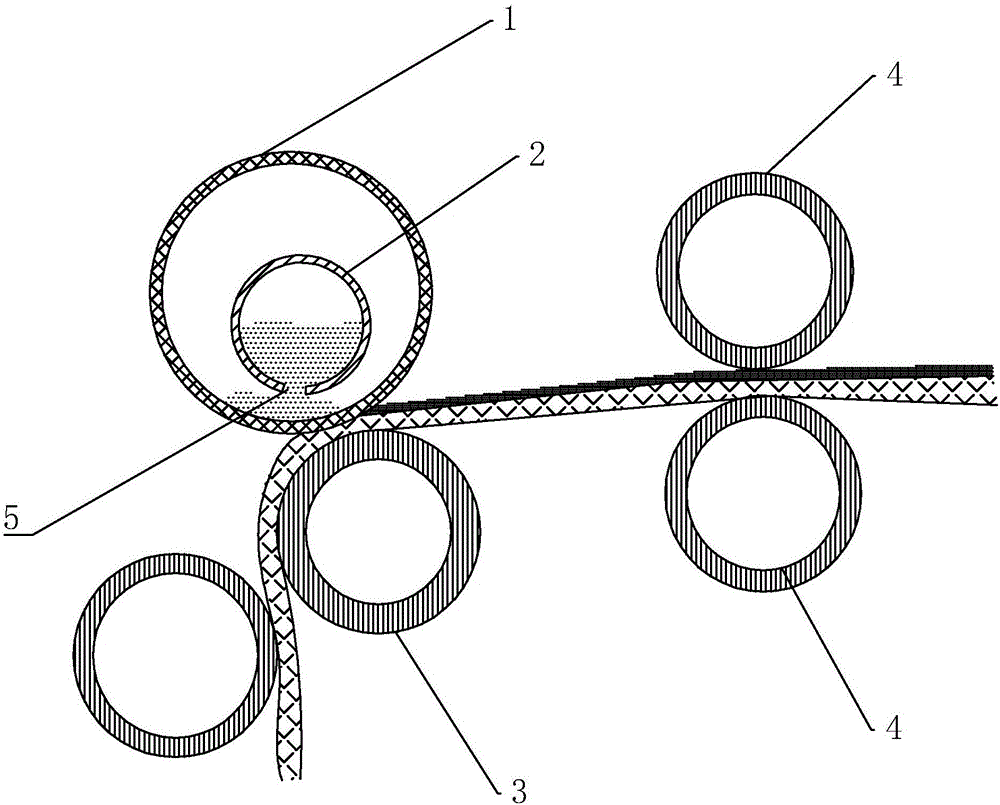

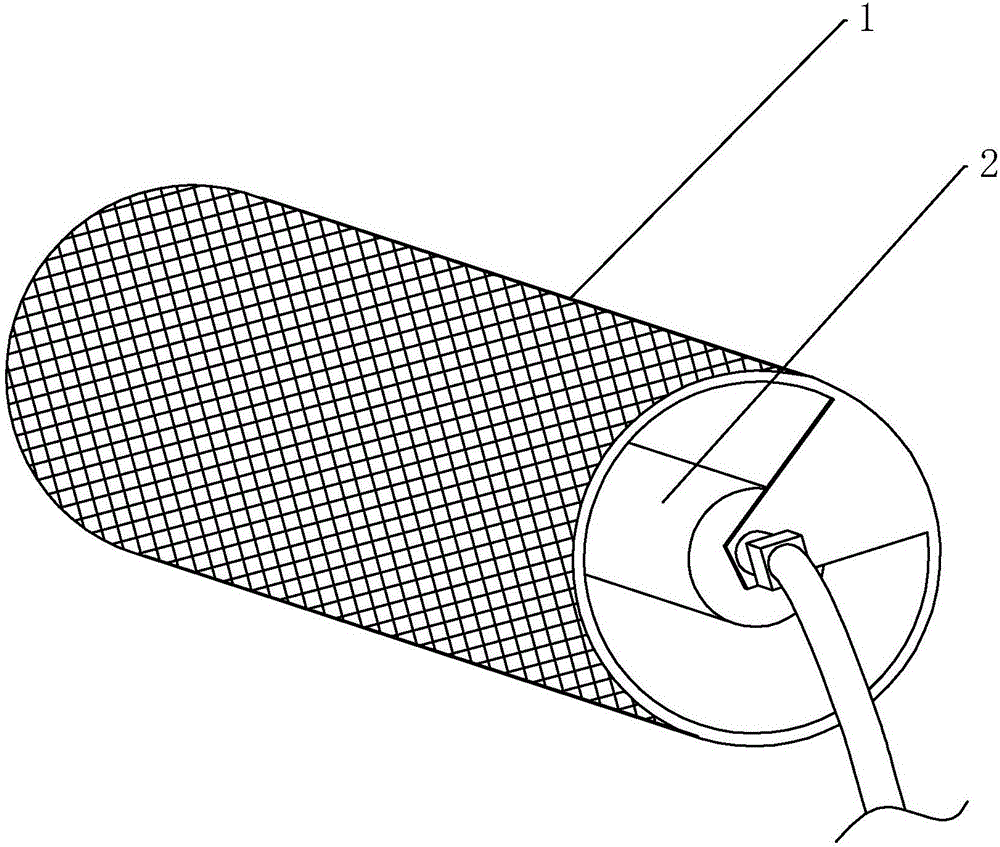

[0036] A rotary screen coating equipment, such as figure 1 and 2 As shown, it includes a coating device and an extrusion device. The coating device includes a cylinder, which cooperates with the first pressure roller, and the first pressure roller will convey the non-woven fabric. The first pressure roller is close to the cylinder One side of the drum is laminated with non-woven fabric. There is a discharge roller inside the cylinder, and a slurry outlet parallel to the axial direction of the cylinder is arranged on the axis of the discharge roller. Both ends of the discharge roller are connected to the pump. The pumping device sends the coating slurry into the discharge roller, and the coating slurry in the discharge roller will be ejected from the slurry outlet under the pressure of the pumping device and reach the inner wall of the cylinder. During the rotation of the cylinder cylinder, the slurry will seep out from the mesh of the cylinder cylinder and be coated on the no...

Embodiment 2

[0040] Step 1: take the following components by weight according to the weight fraction, 40 parts of acrylic resins, 5 parts of epoxy resins, 5 parts of N, N-dinitrosopentamethylenetetramine, 10 parts of water, 1 part of Nano-titanium dioxide, 0.2 part of cetylpyridinium chloride, 0.1 part of acetylene carbon black, 0.2 part of color paste, the above-mentioned components are stirred and mixed evenly and then foamed with a foaming agent, and the foaming ratio is 5 times;

[0041] Step 2: Cloth feeding and coating, the non-woven fabric is sent to the rotary screen coating equipment for coating treatment;

[0042] Step 3: Feeding, the coating slurry after the foaming treatment in step 1 is sprayed into and out of the discharge roller through the pumping device, and the coating slurry seeps out onto the inner wall of the cylinder through the discharge roller, and the cylinder of the cylinder During the rotation process, the coating slurry seeped out of the cylinder and coated on t...

Embodiment 3

[0047] Step 1: take the following components by weight according to the weight fraction, 41 parts of acrylic resins, 6 parts of epoxy resins, 6 parts of N, N-dinitrosopentamethylenetetramine, 11 parts of water, 2 parts Nano-titanium dioxide, 0.3 part of cetylpyridinium chloride, 0.2 part of acetylene carbon black, 0.3 part of color paste, the above-mentioned components are stirred and mixed evenly and then foamed with a foaming agent, and the foaming ratio is 6 times;

[0048] Step 2: Cloth feeding and coating, the non-woven fabric is sent to the rotary screen coating equipment for coating treatment;

[0049] Step 3: Feeding, the coating slurry after the foaming treatment in step 1 is sprayed into and out of the discharge roller through the pumping device, and the coating slurry seeps out onto the inner wall of the cylinder through the discharge roller, and the cylinder of the cylinder During the rotation process, the coating slurry seeped out of the cylinder and coated on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com