Preparation method of composite diaphragm

A technology of composite diaphragm and base film, applied in electrical components, circuits, battery pack components, etc., can solve problems such as weak thermal stability, and achieve the effect of reducing requirements and smooth coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

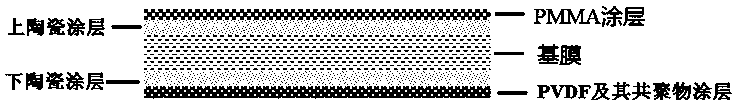

Method used

Image

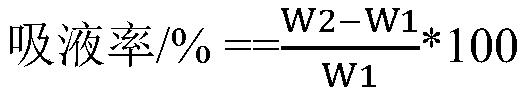

Examples

Embodiment 1

[0026] A preparation method of a composite diaphragm, the method comprises the steps, and its raw materials are all in parts by mass:

[0027] Step 1: Preparation of ceramic slurry: Stir and disperse 40 parts of boehmite, 50 parts of deionized water, 0.1 part of sodium carboxymethylcellulose and 1 part of styrene-acrylic emulsion for 30 minutes to obtain a ceramic slurry;

[0028] Step 2: Prepare PMMA slurry. 40 parts of PMMA, 50 parts of deionized water, 0.1 part of sodium carboxymethylcellulose and 1 part of styrene-acrylic emulsion were stirred and dispersed for 30 minutes to obtain PMMA slurry;

[0029] Step 3: Preparation of PVDF and its copolymer slurry. Stir and disperse 40 parts of polyvinylidene fluoride-hexafluoropropylene, 50 parts of deionized water, 0.1 part of sodium carboxymethyl cellulose and 1 part of styrene-acrylic emulsion for 30 minutes to obtain PVDF and its copolymer slurry;

[0030] Step 4: Coating

[0031] The ceramic slurry prepared in step 1 is coa...

Embodiment 2

[0034] A preparation method of a composite diaphragm, the method comprises the steps, and its raw materials are all in parts by mass:

[0035] Step 1: Preparation of ceramic slurry 45 parts of titanium dioxide, 70 parts of deionized water, 0.4 parts of sodium carboxymethylcellulose and 5 parts of pure acrylic emulsion were stirred and dispersed for 30 minutes to obtain a ceramic slurry;

[0036] Step 2: Prepare PMMA slurry. 45 parts of PMMA, 70 parts of deionized water, 0.4 parts of sodium carboxymethylcellulose and 5 parts of pure acrylic emulsion were stirred and dispersed for 30 minutes to obtain PMMA slurry;

[0037] Step 3: Prepare PVDF and its copolymer slurry. Stir and disperse 45 parts of polyvinylidene fluoride-hexafluoroethylene, 70 parts of deionized water, 0.4 parts of sodium carboxymethylcellulose and 5 parts of pure acrylic emulsion for 30 minutes to obtain PVDF and its copolymer slurry;

[0038] Step 4: Coating

[0039] The ceramic slurry prepared in step 1 is...

Embodiment 3

[0042] A preparation method of a composite diaphragm, the method comprises the steps, and its raw materials are all in parts by mass:

[0043] Step 1: Preparation of ceramic slurry 55 parts of calcium oxide, 80 parts of deionized water, 0.7 parts of sodium carboxymethyl cellulose and 4 parts of ethylene-vinyl acetate copolymer emulsion were stirred and dispersed for 40 minutes to obtain a ceramic slurry;

[0044] Step 2: Prepare PMMA slurry. 55 parts of PMMA, 80 parts of deionized water, 0.7 parts of sodium carboxymethylcellulose and 4 parts of ethylene-vinyl acetate copolymer emulsion were stirred and dispersed for 40 minutes to obtain PMMA slurry;

[0045] Step 3: Preparation of PVDF and its copolymer slurry Mix 55 parts of polyvinylidene fluoride-hexafluoroethylene, 80 parts of deionized water, 0.7 parts of sodium carboxymethyl cellulose and 4 parts of ethylene-vinyl acetate copolymer emulsion, stir and disperse 40min, obtain PVDF and its copolymer slurry;

[0046] Step 4:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com