Super-hydrophilic coating using organic polysilazane as anchor molecule and preparation method thereof

A polysilazane, super-hydrophilic technology, used in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve problems such as unstable coatings and weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

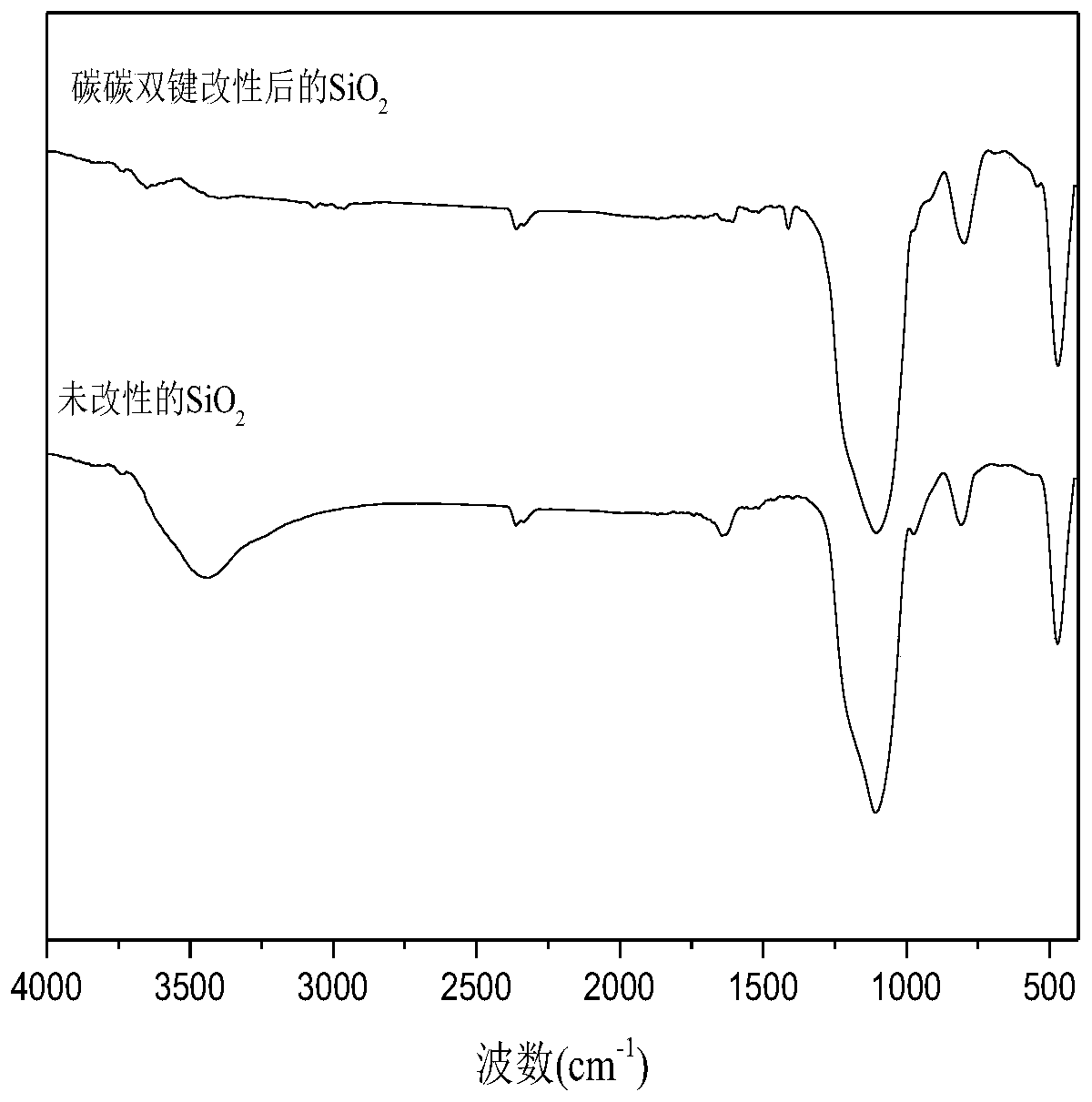

[0042] (1) Modified SiO with carbon-carbon double bonds on the surface 2 Preparation of dispersion liquid of nanoparticles: 3.0g SiO 2 Ultrasonic dispersion of nanoparticles into absolute ethanol, formulated with 1wt% SiO 2 dispersion; then, 1.2g of vinyltrimethoxysilane and 2.0g of ethyl orthosilicate were added to the SiO 2 In the dispersion liquid, adjust the pH value of the dispersion liquid to 4 with an appropriate amount of dilute hydrochloric acid, and react the dispersion liquid system at a temperature of 60°C for 12 hours to obtain a modified SiO with reactive carbon-carbon double bonds on the surface. 2 dispersion of nanoparticles.

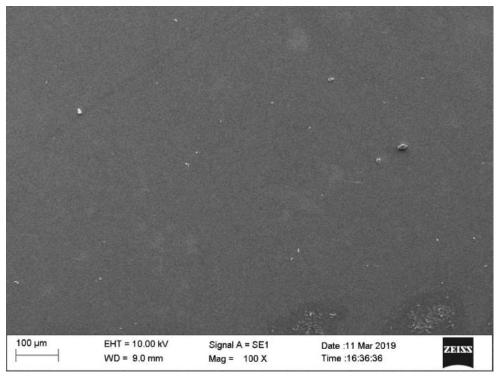

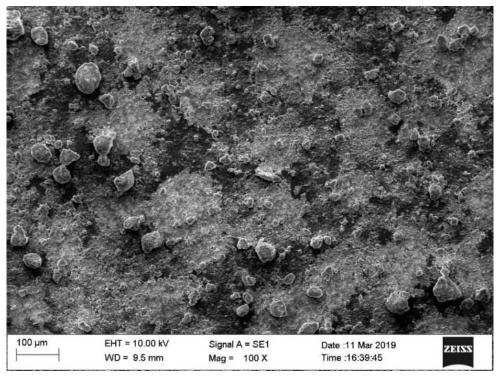

[0043] (2) Reactive organopolysilazane / SiO 2 Preparation of nanoparticle composite coating: dissolve organopolysilazane in acetone to prepare a 5wt% organopolysilazane solution; use spraying method to spray 2.0mL organopolysilazane solution on the pre-washed surface with ethanol The surface of the treated glass substrate (2.5cm×2.5cm...

Embodiment 2

[0055](1) Preparation of a dispersion of modified graphene oxide with a carbon-carbon double bond on the surface: 1.0g graphene oxide is ultrasonically dispersed in isopropanol to form a 1wt% graphene oxide dispersion; then, the Add 1.0g of γ-methacryloxypropyltrimethoxysilane and 2.0g of ethyl orthosilicate to the graphene oxide dispersion, adjust the pH of the dispersion to 4 with an appropriate amount of dilute hydrochloric acid, and make the dispersion The liquid system was reacted at a temperature of 70° C. for 18 hours to obtain a dispersion of modified graphene oxide with reactive carbon-carbon double bonds on the surface.

[0056] (2) Preparation of reactive organopolysilazane / graphene oxide composite coating: dissolve organopolysilazane in tetrahydrofuran, prepare 10wt% organopolysilazane solution; Scrape-coat 2 mL of organopolysilazane solution on the surface of a metal aluminum sheet (2cm×2cm) cleaned with ethanol in advance, and then squeegee-coat 2.0mL of modified...

Embodiment 3

[0068] (1) Preparation of a dispersion of modified montmorillonite with carbon-carbon double bonds on the surface: 0.5g montmorillonite is ultrasonically dispersed in methanol to form a 1wt% montmorillonite dispersion; then, 0.5g Vinyl tris(β-methoxyethoxy)silane and 1.0g ethyl orthosilicate were added to the montmorillonite dispersion, and the pH value of the dispersion was adjusted to 4 with an appropriate amount of dilute hydrochloric acid; the dispersion liquid React at a temperature of 80° C. for 10 hours to obtain a dispersion of modified montmorillonite with carbon-carbon double bonds on the surface.

[0069] (2) Preparation of reactive organopolysilazane / montmorillonite composite coating: dissolve organopolysilazane in ethyl acetate to prepare a 5wt% organopolysilazane solution; spin coating method, spin-coat 2.0mL organopolysilazane solution on the surface of a silicon wafer (3cm×3cm) cleaned with ethanol in advance, and then spin-coat 2.0mL modified montmorillonite o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com