Method for preparing belite-sulphate aluminium cement by using coal ashes and bayer-process red mud

A technology of Belite sulfoaluminate and Bayer red mud, applied in cement production, etc., can solve problems such as high price, hazards to the ecological environment and people's lives, and ineffective utilization of industrial waste residues, so as to reduce production costs , Reduce the effect of calcining energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

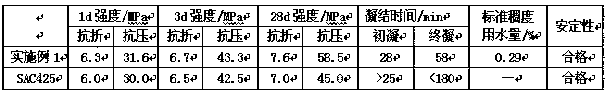

Embodiment 1

[0017] Table 1: Raw material ratio and clinker mineral composition table of embodiment 1 (wherein the percentages are mass percentages)

[0018]

[0019] The specific steps are:

[0020] (1) Put limestone, fly ash, Bayer process red mud, desulfurized gypsum and bauxite into a drying oven respectively, and after drying at 110°C for 24 hours, crush and grind them in a crusher and a ball mill to The 0.08mm sieve residue is less than 8%.

[0021] (2) Mix the raw materials obtained in step (1) according to the ratio in Table 1, put them into the mixing tank, and mix them in the mixer for 20 minutes until they are uniform. After taking them out, add water with 5% of the total mass of the raw materials, and then put Put it in the mold and press it under the hydraulic press to get the raw material test piece.

[0022] (3) Put the raw material test block obtained in step (2) into the muffle furnace, and set the temperature gradient as follows: from room temperature to 300°C, the h...

Embodiment 2

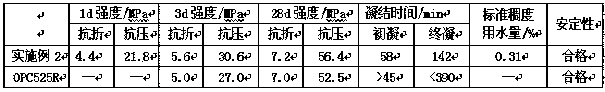

[0030] Table 3: Example 2 Raw Material Proportion and Clinker Mineral Composition Table (wherein the percentages are mass percentages)

[0031]

[0032] The specific steps are:

[0033] (1) After drying limestone, fly ash, Bayer process red mud, desulfurized gypsum and bauxite at 110°C for 24 hours, they are crushed and ground in a crusher and a ball mill respectively until the sieve residue of 0.08mm is less than 8%.

[0034] (2) Mix the raw materials obtained in step (1) according to the ratio in Table 3, put them into the mixing tank, and mix them in the mixer for 20 minutes until they are uniform. After taking them out, add water with 5% of the total mass of the raw materials, and then put Put it in the mold and press it under the hydraulic press to get the raw material test piece.

[0035] (3) Put the raw material test block obtained in step (2) into the muffle furnace, and set the temperature gradient as follows: from room temperature to 300°C, the heating rate is 1...

Embodiment 3

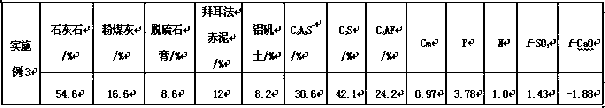

[0043] Table 5: Raw material ratio and clinker mineral composition table of embodiment 3 (wherein the percentages are mass percentages)

[0044]

[0045] The specific steps are:

[0046] (1) Put limestone, fly ash, Bayer process red mud, desulfurized gypsum and bauxite into a drying oven, dry at 110°C for 24 hours, then crush and grind them in a crusher and a ball mill to The 0.08mm sieve residue is less than 8%.

[0047](2) Mix the raw materials obtained in step (1) according to the ratio in Table 5, put them into the mixing tank, and mix them in the mixer for 20 minutes until they are uniform. After taking them out, add water with 5% of the total mass of the raw materials, and then put Put it in the mold and press it under the hydraulic press to get the raw material test block.

[0048] (3) Put the raw material test block obtained in step (2) into the muffle furnace, and set the temperature gradient as follows: from room temperature to 300°C, the heating rate is 10°C / h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com