Method for reclaiming alumina and sodium oxide in red mud of Bayer process

A Bayer process red mud and alumina technology, which is applied in the direction of alumina/aluminum hydroxide, alkali metal oxides, etc., can solve the problems of high energy consumption, restrictions on the recovery and comprehensive utilization of valuable metals in red mud, and low recovery rates. Achieve the effects of reducing production energy consumption, improving industrial operability, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

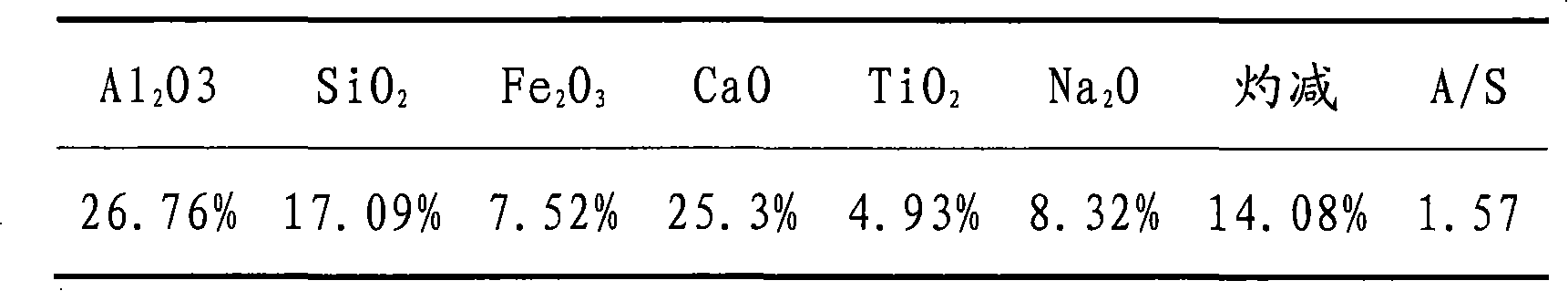

[0018] Use the method of the present invention to reclaim the alumina of Bayer process red mud, take the Bayer process red mud of a factory in Henan as an example, the composition (wt%) of this Bayer process red mud is as follows:

[0019]

[0020] Its recycling steps are:

[0021] Mix the Bayer process red mud with 30% NaOH solution by weight and put it in the reaction kettle. After 1 hour, the mixed reaction product containing lye, sodium aluminate and dealuminated red mud was obtained. After the mixed reaction product was cooled to 100°C, the reaction kettle was taken out and kept in an oven at 100°C for heat preservation and suction filtration, and the alkali containing sodium aluminate was separated. solution and dealuminated red mud, A / S=0.49 (A is the weight percent of alumina and S is the weight percent of silicon oxide) in the dealuminated red mud components at this time, and the recovery rate of alumina from Bayer process red mud is 70.06%;

[0022] The alkali so...

Embodiment 2

[0025] Mix the Bayer process red mud with 45% NaOH solution by weight and place it in the reaction kettle. After 2 hours, the mixed reaction product containing lye, sodium aluminate and dealuminated red mud was obtained. After the mixed reaction product was cooled to 100°C, the reaction kettle was taken out and kept in an oven at 100°C for heat preservation and suction filtration, and the alkali containing sodium aluminate was separated. solution and dealuminated red mud, A / S=0.11 (A is the weight percent of alumina and S is the weight percent of silicon oxide) in the dealuminated red mud components at this time, and the recovery rate of alumina from Bayer process red mud is 93%;

[0026] The alkali solution (filter mother liquor) containing sodium aluminate obtained is put into the crystallization reactor, the caustic ratio of the crystallization mother liquor obtained by filtering after crystallization for 8 hours is raised to 32, and the caustic ratio of the hydrated sodium ...

Embodiment 3

[0029] Mix the Bayer process red mud with a NaOH solution with a concentration of 50% by weight, and add a certain amount of aluminum hydroxide, so that the caustic ratio in the resulting solution is 40, and the proportion by weight is Bayer process red mud: NaOH = 1:8, put it into the reaction kettle and heat up to 230°C, and react at 1.2MPa for 2 hours to obtain a mixed reaction product containing lye, sodium aluminate and dealuminated red mud, after the mixed reaction product is cooled to 100°C , take out the reaction kettle and heat-preserve and suction filter in an oven at 100°C, and separate the alkali solution containing sodium aluminate and the dealuminated red mud. At this time, A / S=0.49 in the dealuminated red mud composition (A is the weight percentage of alumina, S silicon oxide weight percent), the recovery rate of the alumina of Bayer process red mud is 68.79%.

[0030] The alkali solution (filter mother liquor) containing sodium aluminate obtained is put into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com