Method for preparing high-purity ultrafine Al2O3 powder

A high-purity, powder-based technology, applied in alumina/hydroxide preparation, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problems of incomplete aluminum reaction, long production cycle and high production cost, and achieve Fast response, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare materials according to the following mass percentages:

[0036] Metal aluminum 10%

[0037] Catalyst 0.001%

[0038] Water 89.999%;

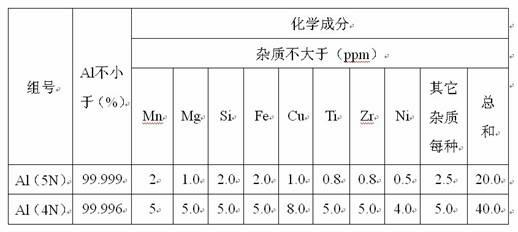

[0039] Among them, water is high-purity water, which is water with a resistivity of 12MΩ·cm after ordinary tap water is treated by conventional two-stage reverse osmosis and electronic mixed bed; commercial high-purity aluminum powder with a purity of 99.996% of metallic aluminum The catalyst is a mixed solution of elemental iodine with a purity of 99.995% and commercially available electronic grade ethanol, with a solid-liquid mass ratio of 1:5;

[0040] (2) After mixing the metal aluminum, water and catalyst in step (1), microwave heating is performed under an electromagnetic wave with a power of 300W and a frequency of 1000MHz for 10 minutes, and then cooled to room temperature to generate aluminum hydroxide precipitate and release Hydrogen, using conventional technology for ventilation during heating and cooling;

[0041] (3) The a...

Embodiment 2

[0043] (1) Prepare materials according to the following mass percentages:

[0044] Metal aluminum 5.996%

[0045] Catalyst 0.004%

[0046] Water 94%;

[0047] Among them, the water is high-purity water, which is water with a resistivity of 13MΩ·cm after ordinary tap water is treated by conventional secondary reverse osmosis and electronic mixed bed; the purity of metal aluminum is 99.999%; it is a rolled metal aluminum sheet , And then washed with high-purity water to remove the remaining impurities on the surface; the catalyst is a mixed solution of elemental iodine with a purity of 99.995% and commercially available electronic grade ethanol, with a solid-liquid ratio of 1:8;

[0048] (2) After mixing the metal aluminum, water and catalyst in step (1), microwave heating is carried out under an electromagnetic wave with a power of 500W and a frequency of 2000MHz for 30 minutes, and then cooled to room temperature to generate aluminum hydroxide precipitate and release Hydrogen, using c...

Embodiment 3

[0051] (1) Prepare materials according to the following mass percentages:

[0052] Metal aluminum 8%

[0053] Catalyst 0.002%

[0054] Water 91.998%;

[0055] Among them, the water is high-purity water, which is water with a resistivity of 14MΩ·cm after ordinary tap water is treated by conventional two-stage reverse osmosis and electronic mixed bed; the purity of metal aluminum is 99.997%; it is aluminum foil made by machining , And then washed with high-purity water to remove the remaining impurities on the surface; the catalyst is a mixed solution of elemental iodine with a purity of 99.995% and commercially available electronic grade ethanol, with a solid-liquid ratio of 1:10;

[0056] (2) After mixing the metal aluminum, water and catalyst in step (1), microwave heating is carried out under an electromagnetic wave with a power of 250W and a frequency of 5000MHz for 5 minutes, and then cooled to room temperature to generate aluminum hydroxide precipitate and release Hydrogen, using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com