Anticorrosion high pressure reactor

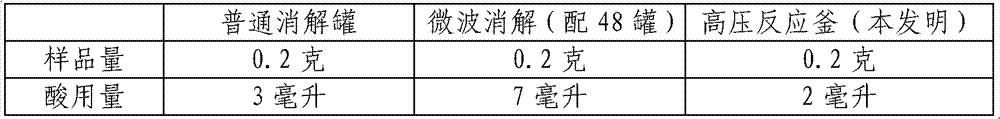

A high-pressure reaction kettle and liner technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as incomplete sample digestion, incomplete digestion, corrosion of stainless steel tanks, etc. , to achieve the effects of improving digestion effect and efficiency, accelerating digestion and reflux, and acid reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

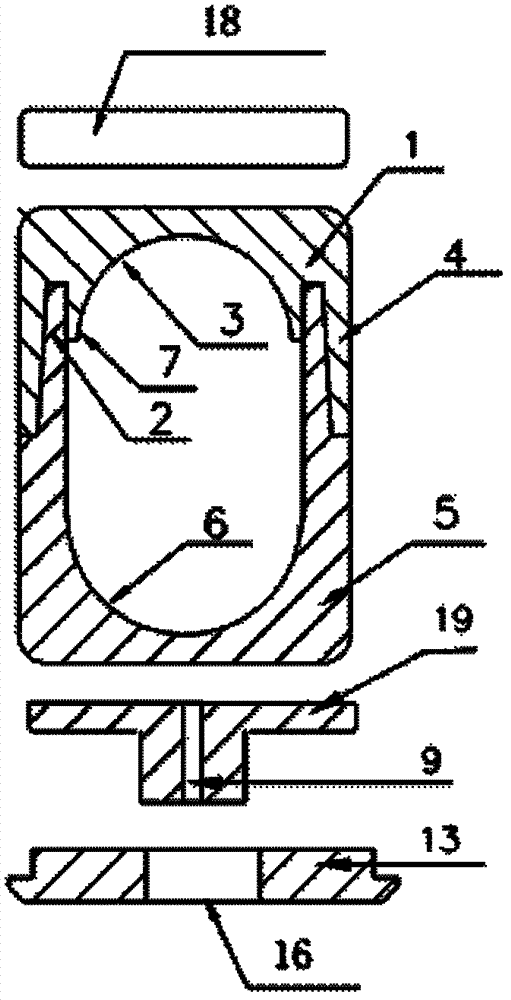

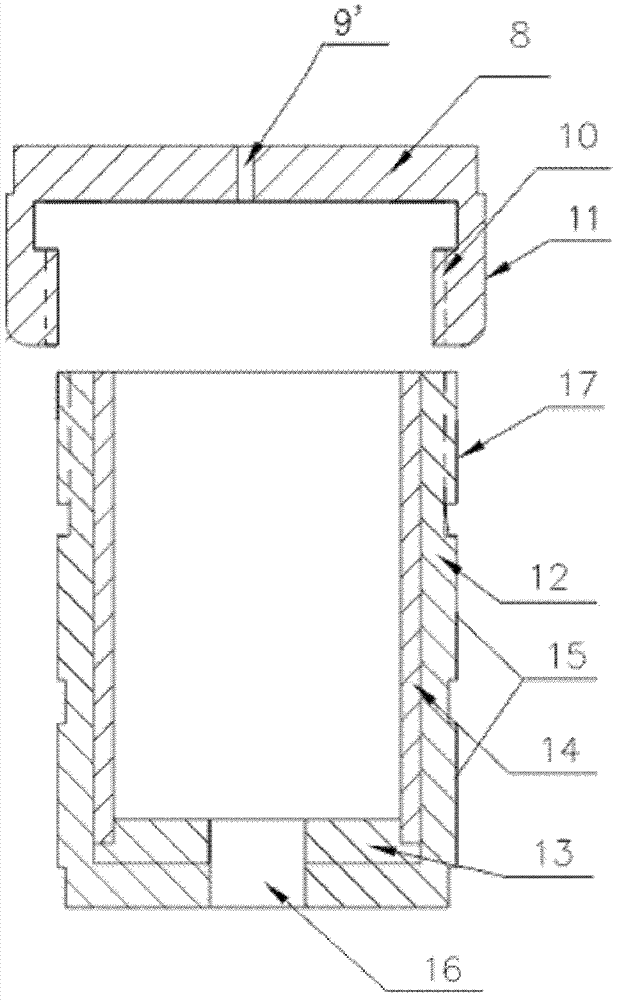

[0017] Such as figure 1 and 2 As shown, the embodiment of the present invention provides

[0018] An anti-corrosion high-pressure reaction kettle, including an outer shell and an inner tank, the inner tank is placed in the outer shell, and the inside of the inner tank is a cavity for holding samples; it is characterized in that: the inner tank includes an inner tank upper cover 1 and an inner tank The lower tank body 5, wherein the inner tank upper cover 1 is sealingly inserted into the top end of the inner tank lower tank body 5, and the axial section of the cavity formed inside the inner tank upper cover 1 and the inner tank lower tank body 5 is Oval.

[0019] The bottom of the outer shell is provided with a stainless steel inner substrate plate 13, and the inner tank is connected with the stainless steel inner substrate plate 13 through a stainless steel centering 19, and steel pad positioning holes 16 are opened on the bottom surface of the stainless steel inner substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com