Production method of 5N high-purity aluminum oxide polycrystal material

A high-purity alumina, production method technology, applied in the direction of aluminate/alumina/aluminum hydroxide purification, etc., can solve problems such as difficult to achieve fixed heating and melting, difficult operation, dust pollution in the operating environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

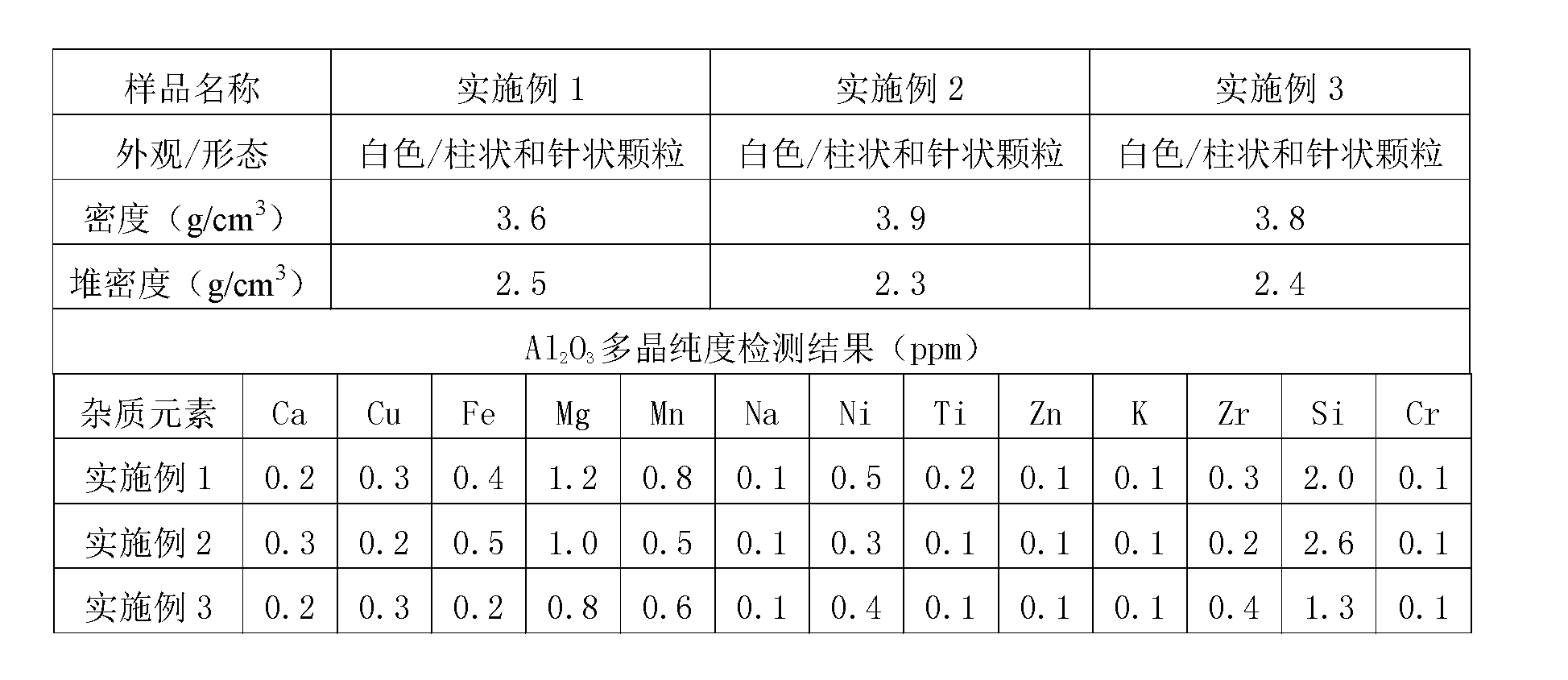

Embodiment 1

[0018] (1) First prepare a high-frequency induction heating furnace (300Kw high-frequency power supply, crucible inner diameter Φ500mm, height 500mm) coated with a chemically stable high-temperature resistant coating for both the cold crucible and the copper tube for the induction coil, and put it into the coated cold crucible Add 50Kg of 5N high-purity alumina powder raw material at one time, the charging volume accounts for 80% of the volume of the crucible, add 5N high-purity metal aluminum sheet with a mass of 270g, select an aluminum sheet with a size of 5×5×0.5mm, and place it in a quadrilateral shape 5cm away from the powder surface;

[0019] (2) Start the circulating soft water cooling system, turn on the power of the high-frequency induction generator, and adjust the frequency to 8MHz, so that the heat released by the oxidation of metal aluminum can melt the surrounding alumina powder, and gradually form a small melting zone. The adjacent alumina powder melts graduall...

Embodiment 2

[0024] (1) First prepare a high-frequency induction heating furnace (300Kw high-frequency power supply, crucible inner diameter Φ500mm, height 500mm) coated with a chemically stable high-temperature resistant coating for both the cold crucible and the copper tube for the induction coil, and put it into the coated cold crucible Add 55Kg of 5N high-purity alumina powder raw material at one time, the charging volume accounts for 95% of the volume of the crucible, add 5N high-purity metal aluminum sheet with a mass of 270g, select an aluminum sheet with a size of 10×10×0.25mm, and place it in a quadrilateral shape 1cm away from the powder surface;

[0025] (2) Start the circulating soft water cooling system, turn on the power of the high-frequency induction generator, and adjust the frequency to 10MHz, so that the heat released by the oxidation of metal aluminum can melt the surrounding alumina powder, and gradually form a small melting zone. The adjacent alumina powder melts grad...

Embodiment 3

[0030] (1) First prepare a high-frequency induction heating furnace (300Kw high-frequency power supply, crucible inner diameter Φ500mm, height 500mm) coated with a chemically stable high-temperature resistant coating for both the cold crucible and the copper tube for the induction coil, and put it into the coated cold crucible Add 50Kg of 5N high-purity alumina powder raw material at one time, the charging volume accounts for 80% of the volume of the crucible, add 5N high-purity metal aluminum sheet with a mass of 270g, select an aluminum sheet with a size of 20×20×0.1mm, and place it in a quadrilateral shape 5cm away from the powder surface;

[0031] (2) Start the circulating soft water cooling system, turn on the power supply of the high-frequency induction generator, and adjust the frequency to 9MHz, so that the heat released by the oxidation of metal aluminum can melt the surrounding alumina powder, and gradually form a small melting zone. The adjacent alumina powder melts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com