Two-component air-dry water-based finishing varnish

A glossy varnish, two-component technology, applied in the direction of coating, can solve the problem of not meeting the performance of water-based coatings, and achieve the effects of excellent water resistance, no pollution to the environment, and strong decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

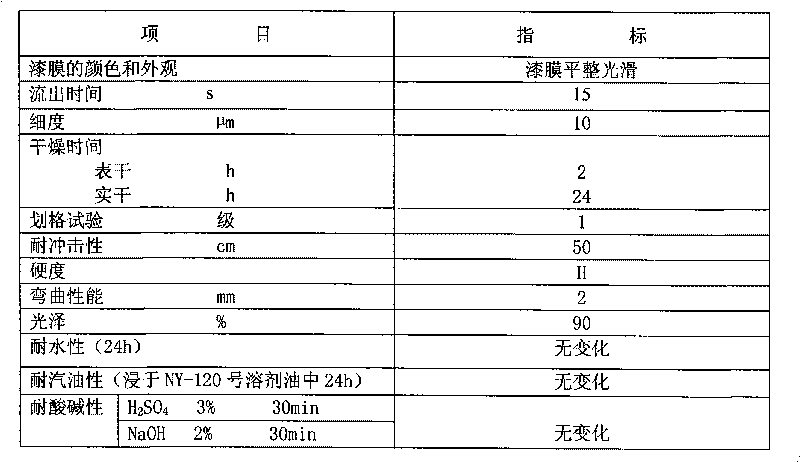

Embodiment 1

[0022] Weigh 15kg of deionized water as raw material, 0.05kg of organosilicon defoamer, 45kg of hydroxyl group-containing polyacrylate emulsion, 0.05kg of polyether modified polydimethylsiloxane leveling agent, 1kg Modified urea thickener.

[0023] Stir deionized water, polyacrylate emulsion containing hydroxyl groups, silicone defoamer, and polyether-modified polydimethylsiloxane in a dispersion tank, and feed in the above order at intervals of 5 minutes each time. After all the feeding was completed and stirred for another 16 minutes, the stirring was stopped.

[0024] Add the modified urea thickener to the dispersion tank and stir for 10 minutes to stop stirring. Visually check whether the varnish is fully mixed. If not, continue stirring until it is fully mixed.

[0025] Inspection, check whether the appearance, viscosity, and pH value meet the central control index, and filter with 180 mesh silk cloth. 61.1 kg of product was produced.

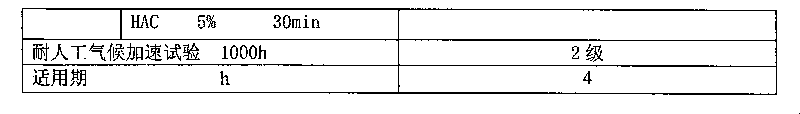

Embodiment 2

[0030] Weigh the deionized water of 20kg of raw materials, the organosilicon defoamer of 0.1kg, the polyacrylate emulsion containing hydroxyl group of 55kg, the polyether modified polydimethylsiloxane leveling agent of 0.3kg, 1.5 kg of modified urea thickener.

[0031] Stir deionized water, polyacrylate emulsion containing hydroxyl groups, silicone defoamer, and polyether-modified polydimethylsiloxane in a dispersion tank, and feed in the above order at intervals of 5 minutes each time. After all the feeding was completed and stirred for another 16 minutes, the stirring was stopped.

[0032] Add the modified urea thickener to the dispersion tank and stir for 10 minutes to stop stirring. Visually check whether the varnish is fully mixed. If not, continue stirring until it is fully mixed.

[0033] Inspection, check whether the appearance, viscosity, and pH value meet the central control index, and filter with 180 mesh silk cloth. 76.9 kg of product was produced.

[0034] Appl...

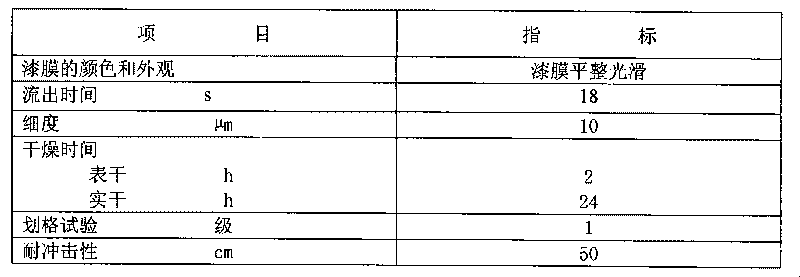

Embodiment 3

[0038] Weigh the deionized water of 18kg of raw materials, the organosilicon defoamer of 0.08kg, the polyacrylate emulsion containing hydroxyl group of 50kg, the polyether modified polydimethylsiloxane leveling agent of 0.2kg, 1.12 kg of modified urea thickener.

[0039] Stir deionized water, polyacrylate emulsion containing hydroxyl groups, silicone defoamer, and polyether-modified polydimethylsiloxane in a dispersion tank, and feed in the above order at intervals of 5 minutes each time. After all the feeding is completed and stirred for another 18 minutes, the stirring is stopped.

[0040] Add the modified urea thickener to the dispersion tank and stir for 10 minutes to stop stirring. Visually check whether the varnish is fully mixed. If not, continue stirring until it is fully mixed.

[0041] Inspection, check whether the appearance, viscosity, and pH value meet the central control index, and filter with 180 mesh silk cloth. 69.4 kg of product was produced.

[0042] Appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com