Low-temperature hot-sealed coating film and manufacturing method thereof

A low-temperature heat-sealing and film-coating technology, which is applied in the direction of liquid-coating devices, coatings, and pre-treated surfaces, can solve the problems of low sealing temperature, high sealing temperature, and low heat-sealing strength. Achieve the effects of increasing the glass transition temperature, avoiding coating anti-sticking, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of low-temperature heat-sealing coating

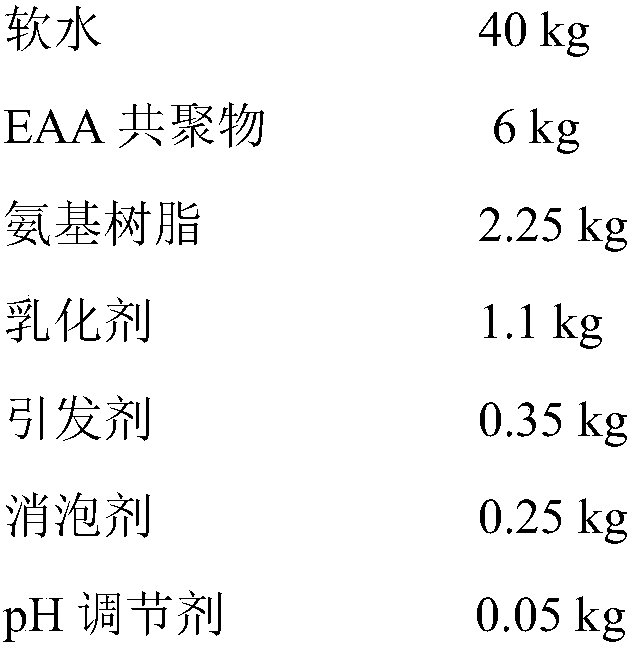

[0024]

[0025] 1. Preparation of raw materials:

[0026] (1), first add 4kg of soft water in the batching tank, then add the weighed initiator, start stirring to fully dissolve and mix, and make a mixed initiator solution;

[0027] (2), first add 8kg of soft water into the batching tank, then add the weighed emulsifier, start stirring to fully dissolve and mix, and make an emulsifier solution;

[0028] (3) First add 28kg of soft water to the reactor, then add the weighed EAA copolymer and amino resin, close the inlet and outlet valves of the reactor, and turn on the vacuum pump to evacuate the reactor. When the pressure reaches -0.08 MPa and then pass nitrogen gas inside, and replace 3 times by vacuuming→adding nitrogen→vacuumizing to empty the oxygen in the reactor.

[0029] 2. Coating emulsification reaction:

[0030] Turn the stirring speed of the reactor to 1500r / min, and turn on the heating. When the ...

Embodiment 2

[0034] (1) Preparation of low-temperature heat-sealing coating

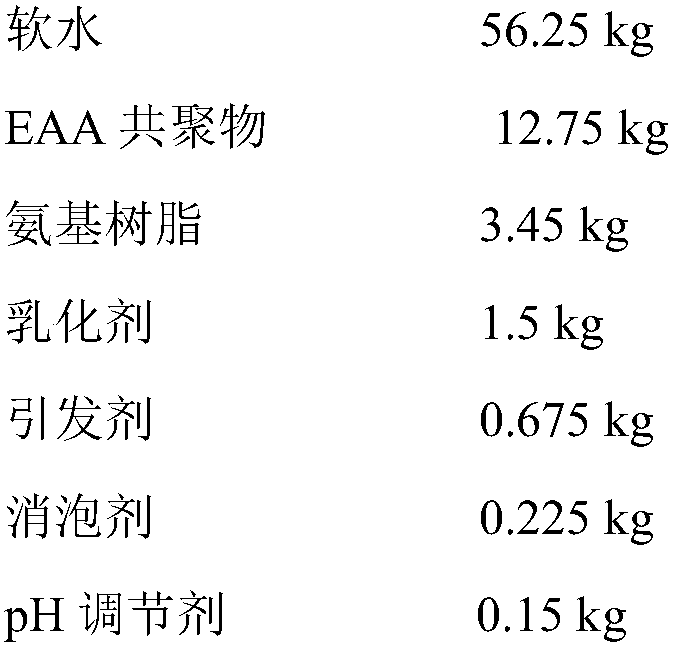

[0035]

[0036] 1. Preparation of raw materials:

[0037] (1), first add 5.625kg of soft water in the batching tank, then add the weighed initiator, start stirring and fully dissolve and mix to make a mixed initiator solution;

[0038] (2), first add 11.25kg of soft water in the batching tank, then add the weighed emulsifier, start stirring to fully dissolve and mix, and make an emulsifier solution;

[0039] (3) First add 39.375kg of soft water into the reactor, then add the weighed EAA copolymer and amino resin, close the inlet and outlet valves of the reactor, and turn on the vacuum pump to evacuate the reactor, when the pressure reaches- After 0.08MPa, nitrogen gas is passed inside, and the oxygen in the reactor is evacuated by vacuuming→adding nitrogen→vacuumizing for 3 times.

[0040] 2. Coating emulsification reaction:

[0041] Turn on the stirring speed of the reactor to 2000r / min, and turn on the he...

Embodiment 3

[0045] (1) Preparation of low-temperature heat-sealing coating

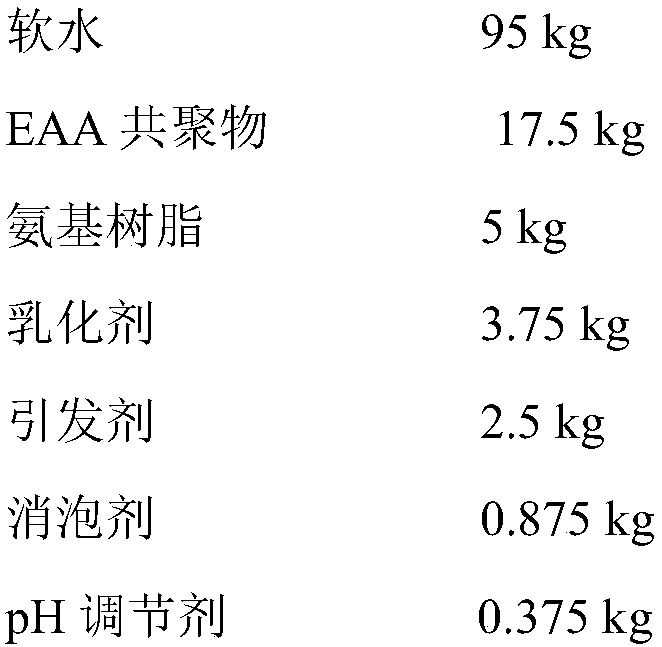

[0046]

[0047] 1. Preparation of raw materials:

[0048] (1), first add 9.5kg of soft water in the batching tank, then add the weighed initiator, start stirring to fully dissolve and mix, and make a mixed initiator solution;

[0049] (2), first add 19kg of soft water in the batching tank, then add the weighed emulsifier, start stirring to fully dissolve and mix, and make an emulsifier solution;

[0050] (3) First add 66.5kg of soft water into the reactor, then add the weighed EAA copolymer and amino resin, close the inlet and outlet valves of the reactor, turn on the vacuum pump to vacuum the reactor, when the pressure reaches- After 0.08MPa, nitrogen gas is passed inside, and the oxygen in the reactor is evacuated by vacuuming→adding nitrogen→vacuumizing for 3 times.

[0051] 2. Coating emulsification reaction:

[0052] Turn the stirring speed of the reactor to 1600r / min, and turn on the heating. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com