Magnetic separation concentration method

A magnetic separation and enrichment technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of incomplete recovery of broken small steel particles, low dosage, and reduced chemical activity of steel slag, etc. Achieve cleaner production, improve separation accuracy, and avoid the effect of reducing chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

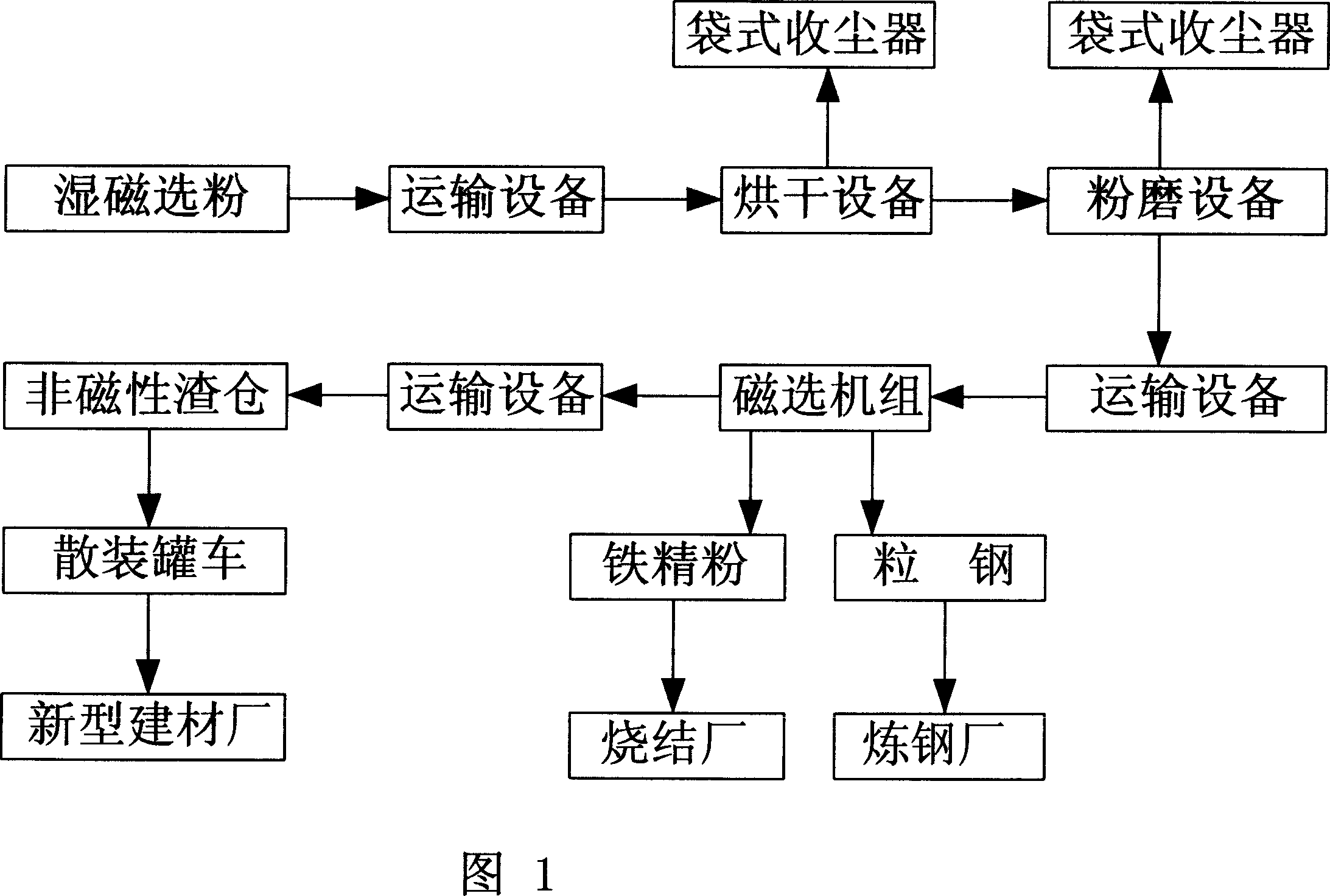

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] See Figure 1, a process method for enriching magnetic separation powder. Firstly, the wet magnetic separation powder with a particle size of 0-30mm and a moisture content of ≤20% is transported by car to the raw material storage yard, and then sent to the drying machine by a forklift The transition silo in front of the machine is sent into the dryer through the vibrating feeder, belt conveyor, and hoist. The raw materials are preheated in the dryer and dried at a temperature below 950°C to reduce the moisture content to 5%. Next, during the drying process, the thermal stress of the granular steel will act on the slag powder on the surface due to thermal expansion, which weakens the adhesion, and the magnetic slag and non-magnetic slag particles that adhere to each other are preliminarily separated; the temperature of the magnetic separation powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com