Gum leakage method of bamboo-wood rods with high water content

A high moisture content, bamboo and wood technology, applied in the direction of wood processing equipment, pretreatment of molding materials, household components, etc., can solve the problem of uneven dipping, reduce the amount of drying evaporation water, solve the problem of uneven dipping, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

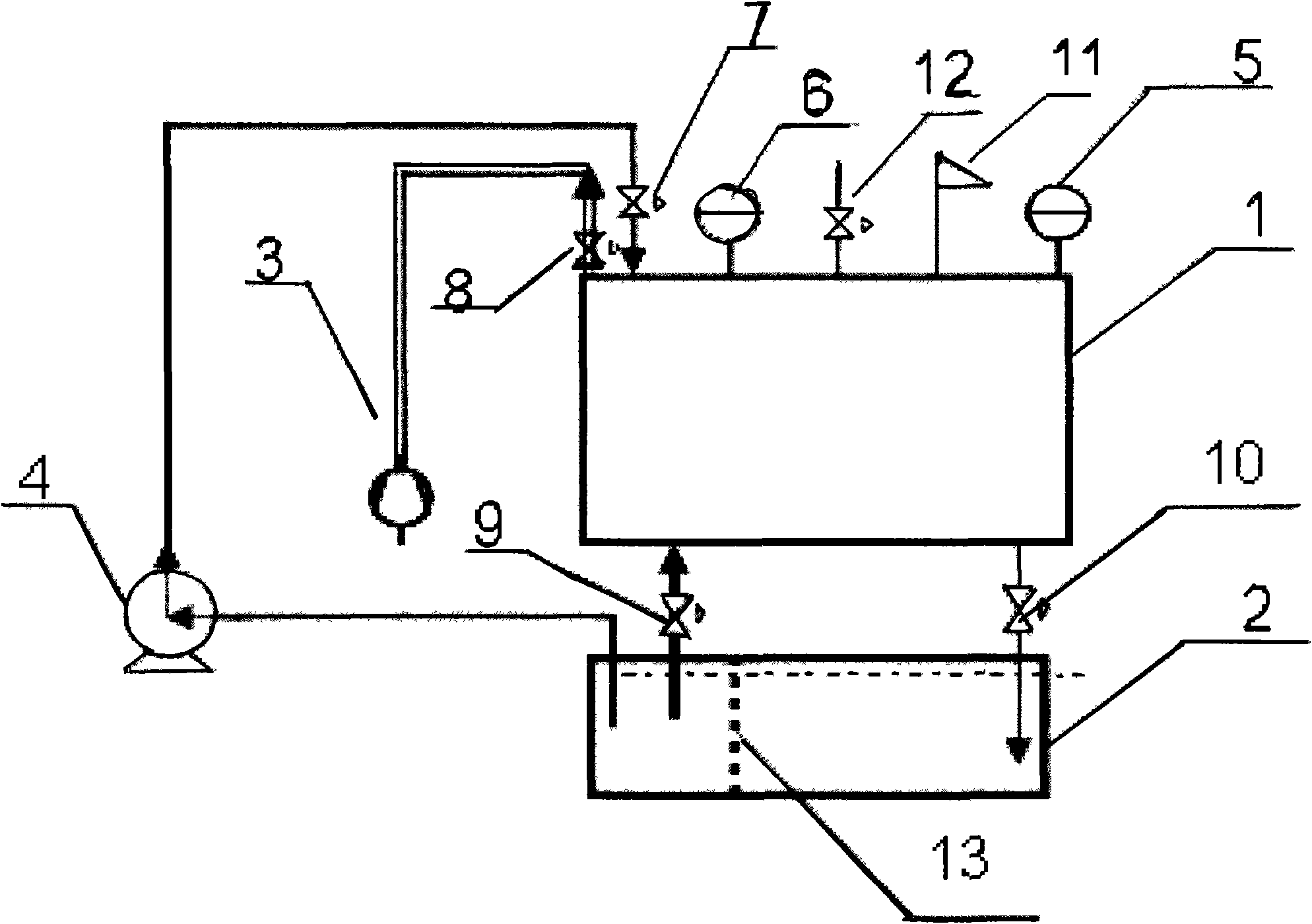

Method used

Image

Examples

Embodiment 1

[0022] 1. High moisture content carbonized bamboo stick seepage:

[0023] 1) Detect that the moisture content of the carbonized wet bamboo strips is 52%, calculate and determine the concentration of the glue solution, configure the corresponding glue, and inject the prepared glue into the glue storage pool; 2) Take the carbonized bamboo strips with high moisture content and put them into the pressure Inside the container; 3) Vacuum fluffing treatment: open the vacuum system, and control the vacuum pressure at 0.070-0.09MPa, preferably 0.078MPa, and maintain it for a period of time; 4) Close the vacuum system, and inject the glue into the pressure container; 5 ) Turn on the pressurization system, fill the pressure vessel with glue, and pressurize it to 0.4-1.0Mpa, the preferred pressure is 0.6MPa, and keep it for a period of time to release the pressure and discharge the glue; 6) Turn on the vacuum system again to complete Vacuum draining treatment; 7) discharge.

[0024] 2. Q...

Embodiment 2

[0029] 1. High moisture content bleached bamboo strips:

[0030] 1) Detect that the moisture content of bleached wet bamboo strips is 56%, calculate and determine the glue concentration, prepare the corresponding glue, and inject the prepared glue into the glue storage pool; 2) Take the bleached bamboo strips with high moisture content and put them into a pressure vessel 3) Vacuum fluffing treatment: open the vacuum system, and control the vacuum pressure at 0.070-0.09MPa, preferably 0.078MPa, and maintain it for a period of time; 4) Close the vacuum system, and inject the glue into the pressure vessel; 5) Turn on the pressurization system, fill the pressure vessel with glue, and pressurize it to 0.4-1.0Mpa, preferably 0.6MPa, and maintain it for a period of time to release the pressure and discharge the glue; 6) Turn on the vacuum system again to complete the vacuum Drain and process; 7) discharging.

[0031] 2. Quality inspection

[0032] After drying the bleached bamboo s...

Embodiment 3

[0036] 1. Infiltration of natural bamboo strips with high moisture content:

[0037] 1) Detect that the moisture content of the natural-color wet bamboo strips is 50%, calculate and determine the concentration of the glue solution, configure the corresponding glue, and inject the prepared glue into the glue storage tank; 2) Take the natural-color high moisture content bamboo strips and put them into the pressure vessel ;3) Vacuum fluffy treatment: open the vacuum system, and control the vacuum pressure at 0.070-0.09MPa, preferably 0.078MPa, and maintain it for a period of time; 4) Close the vacuum system, inject the glue into the pressure vessel; 5) Open Pressurization system, fill the pressure vessel with glue, and pressurize to 0.4-1.0Mpa, the preferred pressure is 0.6MPa, and maintain it for a period of time to release the pressure and discharge the glue; 6) Turn on the vacuum system again to complete the vacuum draining Dry processing; 7) discharging.

[0038] 2. Quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com