Impregnation equipment and method thereof

A technology of dipping and equipment, applied in the field of rubber felt, can solve the problems of large floor space, complicated operation and high equipment investment, and achieve the effect of small floor space, less equipment investment and flexible production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A kind of dipping method that present embodiment provides, it comprises the steps:

[0093] In step S1, the glass fiber mat is arranged in a roll shape;

[0094] Step S2, using high pressure to force the glue solution to flow through the glass fiber felt along the radial direction of the glass fiber felt roll.

[0095] In the above embodiment, more preferably, the glass fiber mat reel is placed horizontally, and the pressure value of the glue solution decreases gradually in the axial direction of the reel and in the direction extending from the middle of the reel to both ends thereof.

[0096] Specifically, in the radial direction of the glass fiber mat reel, the glue solution flows from the inside of the reel to the outside thereof, or the glue solution flows from the outside of the reel to the inside thereof. In the axial direction of the reel, the pressure value of the glue is normally distributed. When dipping, alternately input the glue solution from both ends of...

Embodiment 2

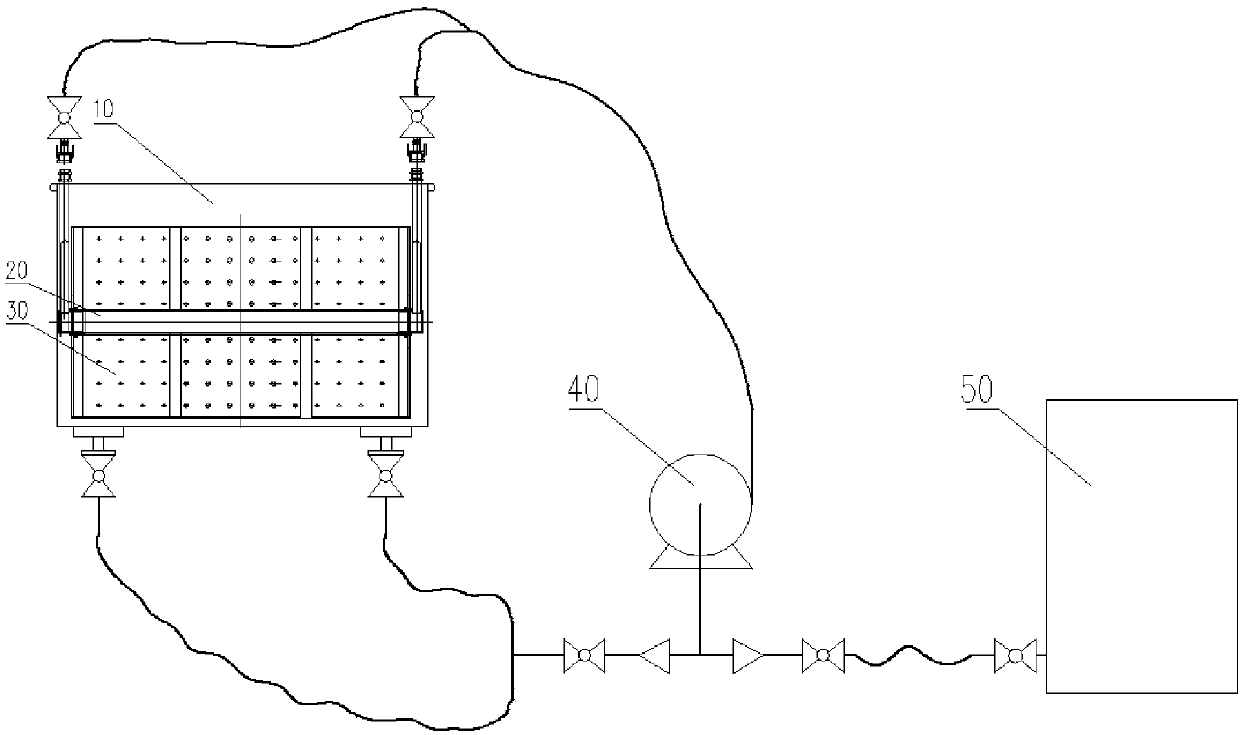

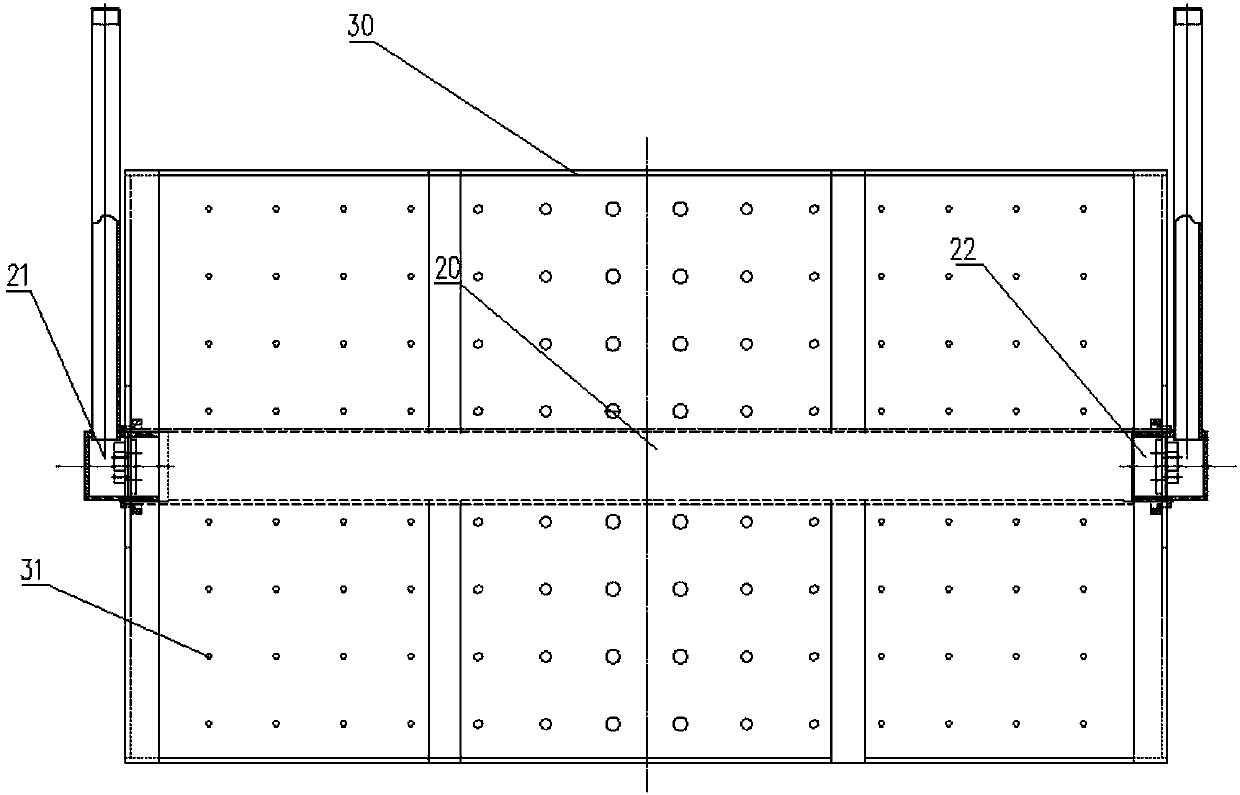

[0101] Such as Figure 1-7 As shown, this embodiment discloses a dipping equipment, which includes: a rubber injection sleeve 20, a pressure barrel 30 and a pump body 40;

[0102] The pressure-bearing barrel 30 is set outside the injection sleeve 20, and an annular cavity for accommodating the glass fiber felt reel is arranged between the two;

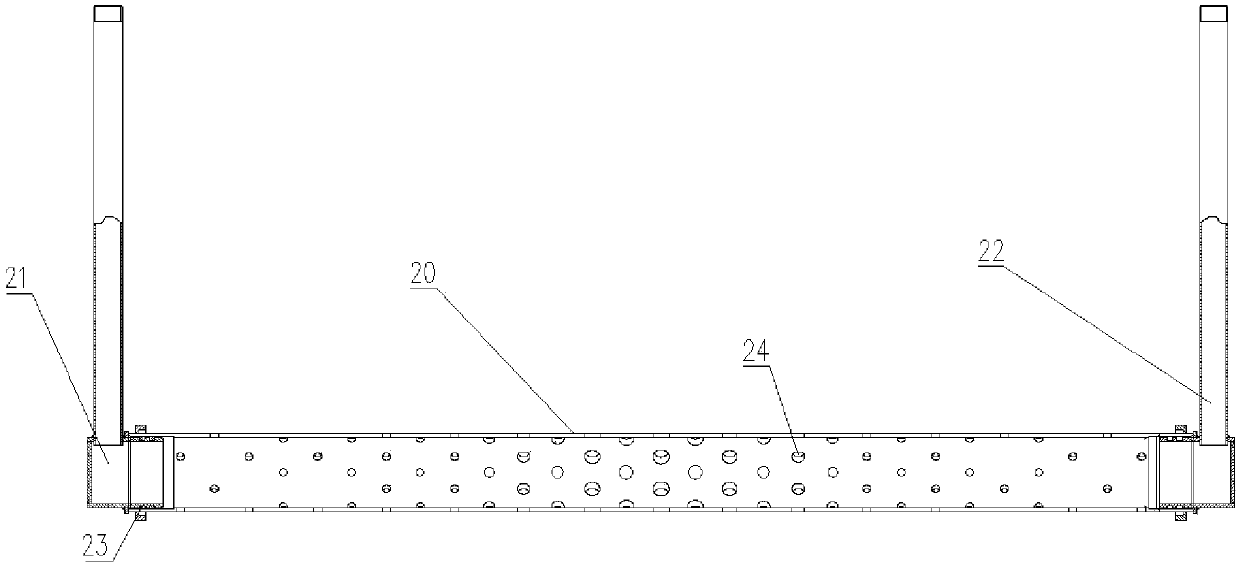

[0103] Such as image 3 As shown, the outer circular side of the injection sleeve 20 is provided with an injection hole 24 communicating with the inner and outer sides of the injection sleeve 20;

[0104] Such as figure 2 As shown, the outer circular side of the pressure barrel 30 is provided with a glue discharge hole 31 communicating with the inside and outside of the annular cavity;

[0105] The glass fiber felt is wound on the injection sleeve 20 to form a glass fiber felt roll;

[0106] The pump body 40 communicates with the cylinder cavity of the glue injection sleeve 20 through a pipeline, and is used to inject glue into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com