Patents

Literature

31results about How to "Save labor wages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

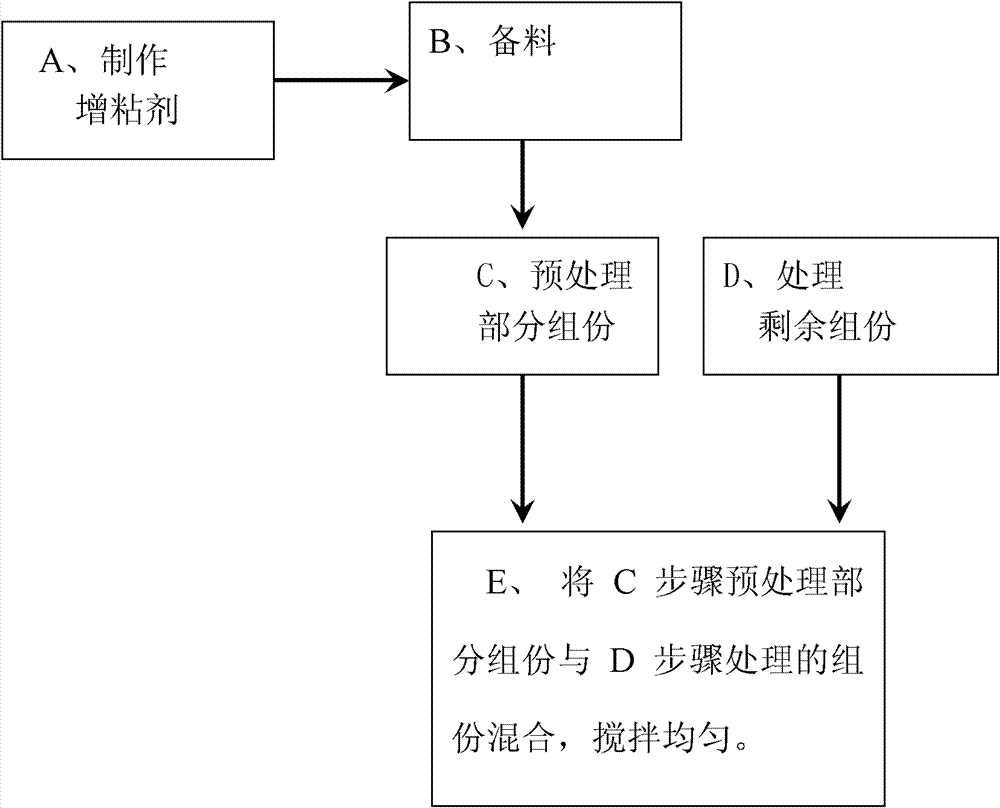

Coupling compound moulded coal binder and preparation method thereof

InactiveCN101798538AWater evaporates quicklyIncrease production capacitySolid fuelsCross-linkCellulose

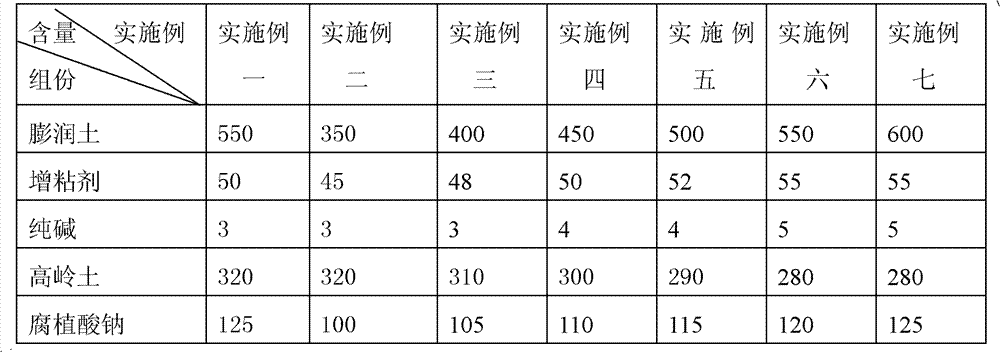

The invention discloses a coupling compound moulded coal binder and a preparation method thereof. The coupling compound moulded coal binder is a mixture prepared by mixing bentonite, tackifier, sodium carbonate, kaolin and sodium humate; the mixture comprises the following components in parts by weight: 350-600 parts of the bentonite, 45-55 parts of the tackifier, 3-5 parts of the sodium carbonate, 280-320 parts of the kaolin and 100-125 parts of the sodium humate; the tackifier is prepared by smashing 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stalk, 3-5 parts by weight of modified starch and 0.2-0.5 part by weight of cross-linking agent into 50-100 meshes, and mxing the smashed materials. The preparation method comprises the following steps: preparing the tackifier, stocking, pretreating parts of the components, mixing, stirring and the like. The moulded coal binder has favorable waterabsorbtion performance, the moisture of an extruded and shaped coal bar is quickly evaporated and is easy to dry, thus solving the problems of high raw coal moisture, difficult moulded coal production and low shaping rate in rainy days in the south of China.

Owner:柳州化工股份有限公司 +2

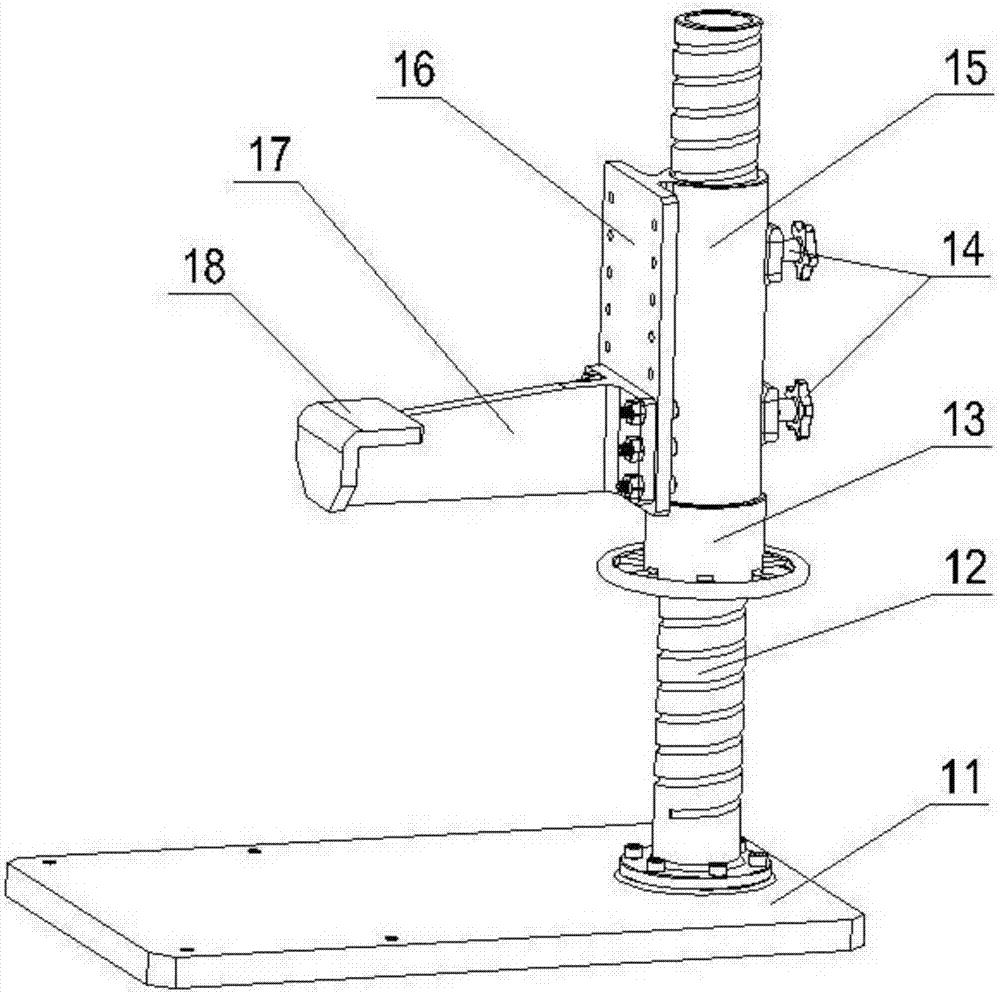

Hammering-type meat emulsion maker

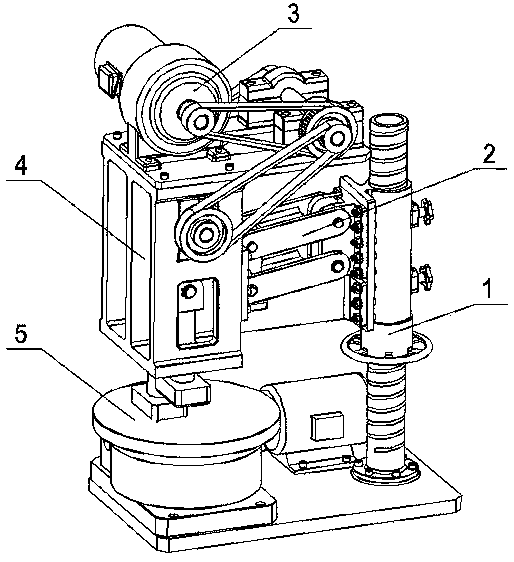

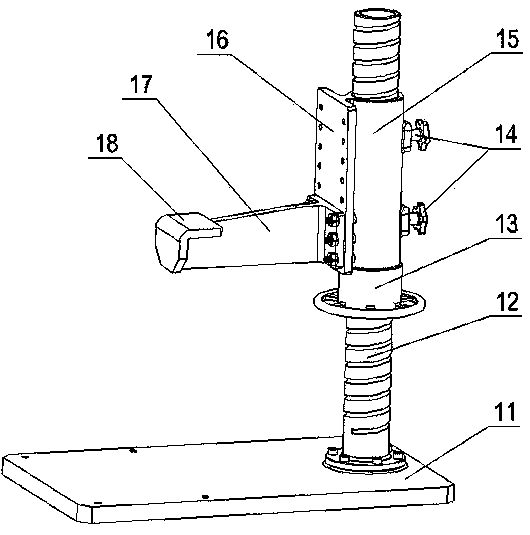

The invention discloses a hammering-type meat emulsion maker. The hammering-type meat emulsion maker solves the technical problems that processing of food material beef emulsion in a background technique needs to be completed in the manner of performing manual and continuous hammering with an iron bar or a solid wood bar, so that the efficiency is low; and besides, an air hammer is used for replacing manual operation, so that the defects of being large in size and large in noise exist. The invention adopts the technical scheme that the hammering-type meat emulsion maker comprises a support frame, wherein a rotating working table is vertically arranged on the support frame, and cantilevers are arranged on the support frame; a crank connecting link mechanism which is matched with the rotating working table for operation and is used for hammering meat is arranged on the cantilevers; and a power part for driving the crank connecting link mechanism to move is arranged at the top of the crank connecting link mechanism. The hammering-type meat emulsion maker disclosed by the invention has the beneficial effect that the machine size is small, the size of the hammering-type meat emulsion maker is smaller than that of the air hammer, besides, noise generated by exhaust of the air hammer does not exist, and the noise is low.

Owner:青海五三六九生态牧业科技有限公司

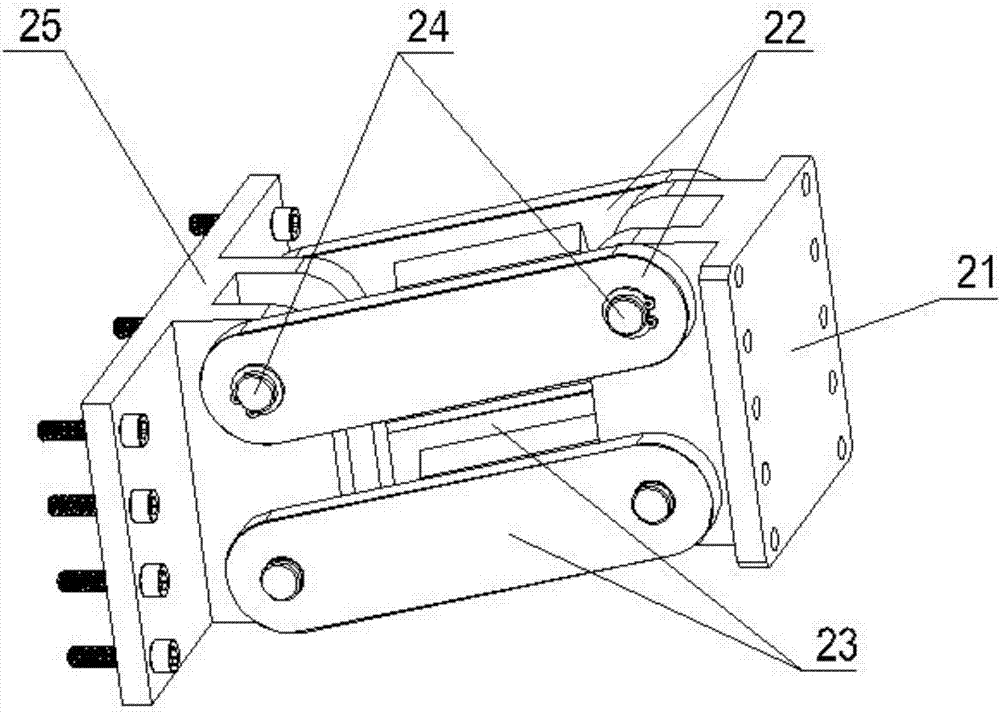

Method for continuously manufacturing electric welding rod and short welding rod of nanometer coating compatibly

InactiveCN1778514ALow priceImprove welding qualityWelding/cutting media/materialsSoldering mediaProduction lineEngineering

A technology for manufacturing both short welding electrodes and the coiled continuous welding electrode, which are coated by a nano-class coated layer features that its mechanical apparatuses are arranged to become a program-controlled parallel small production line.

Owner:高忠民

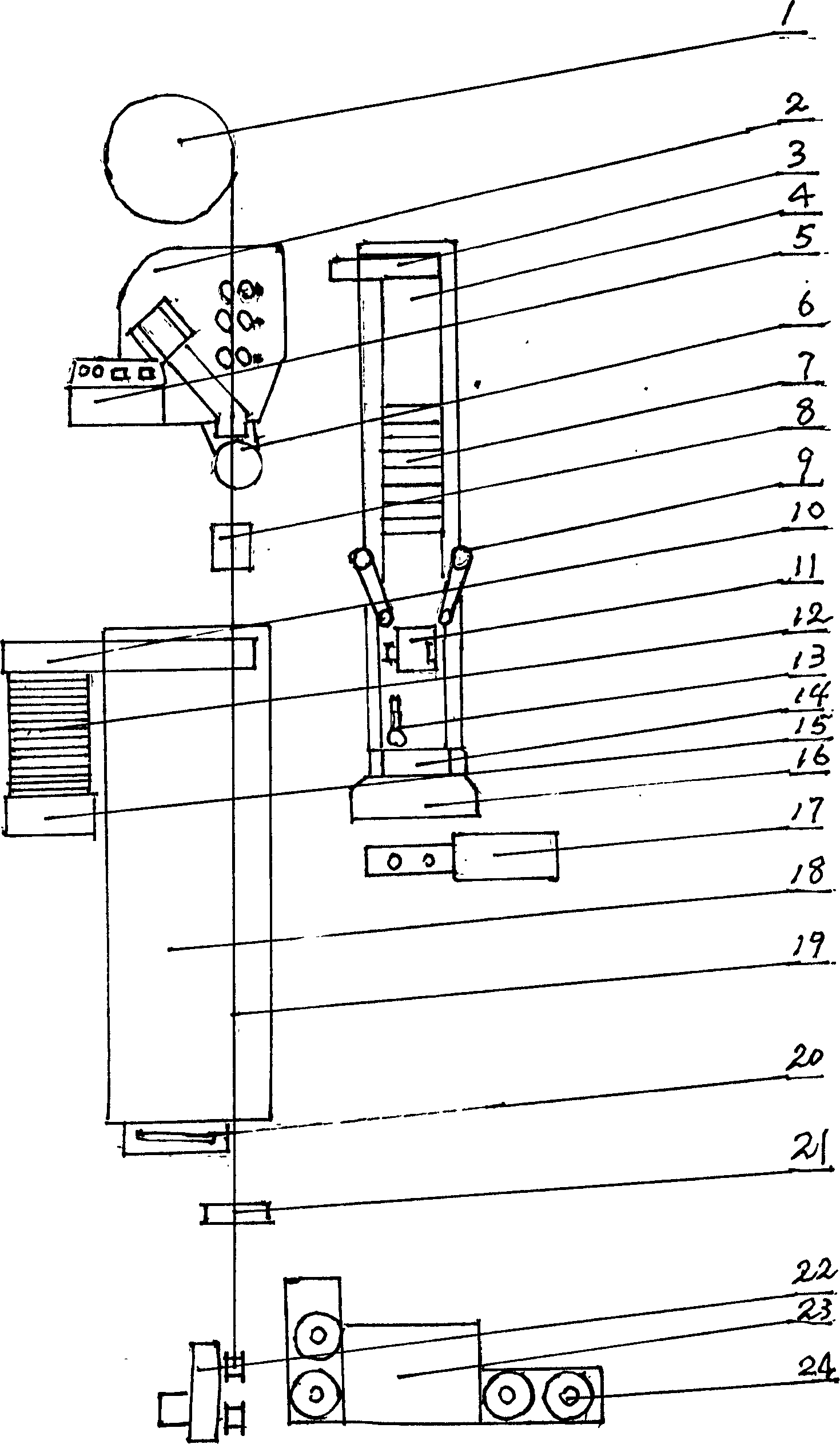

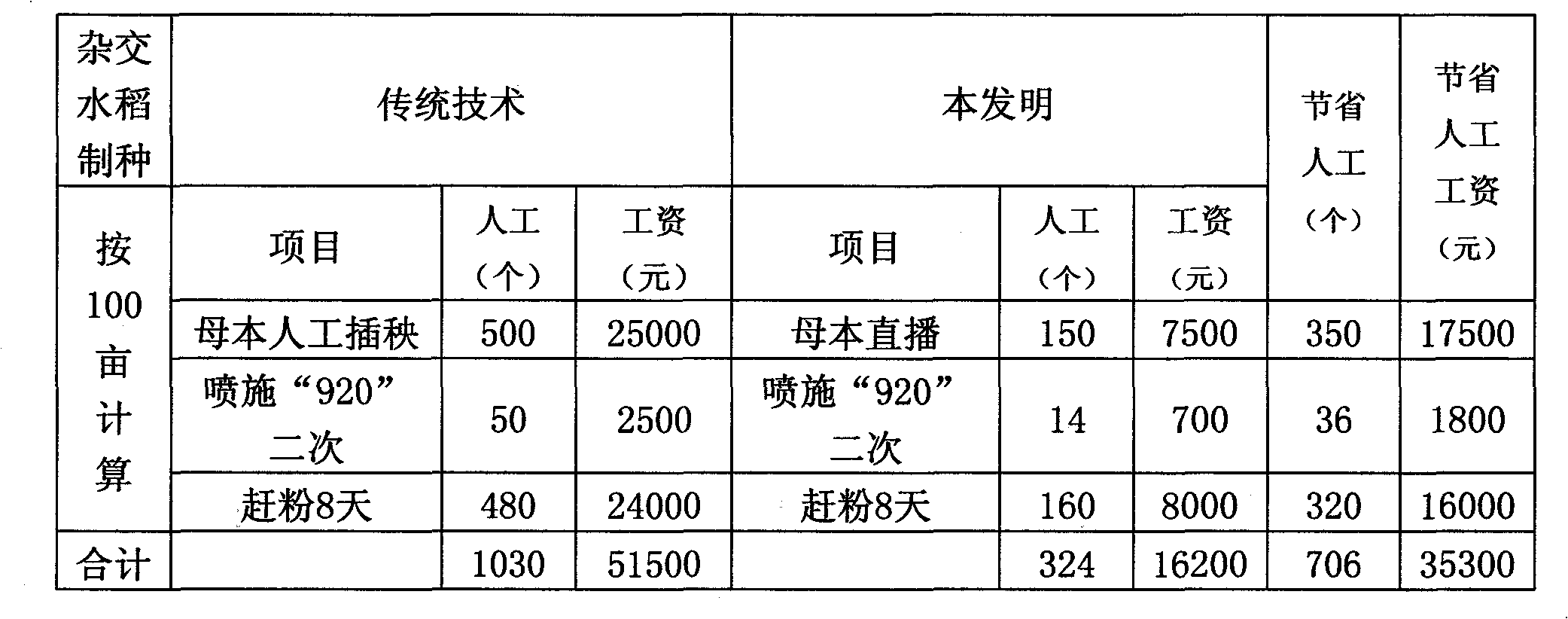

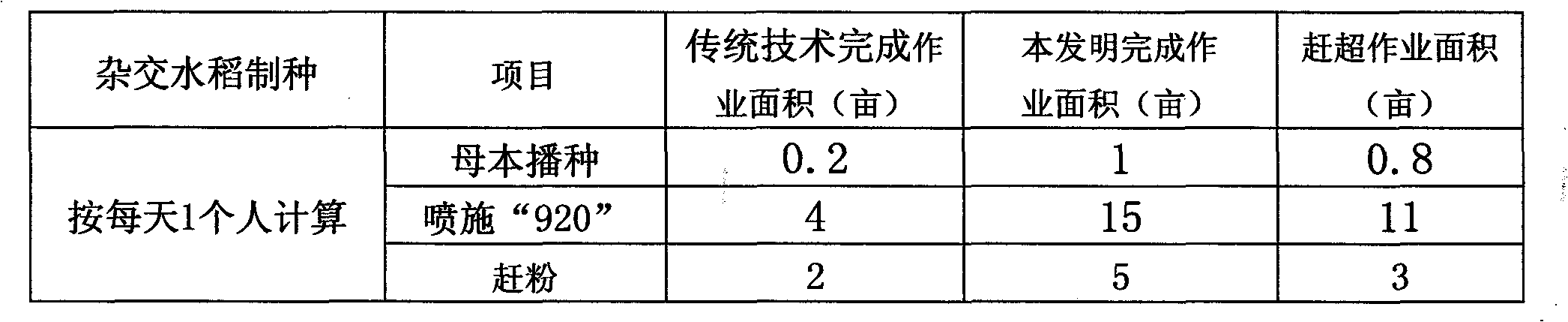

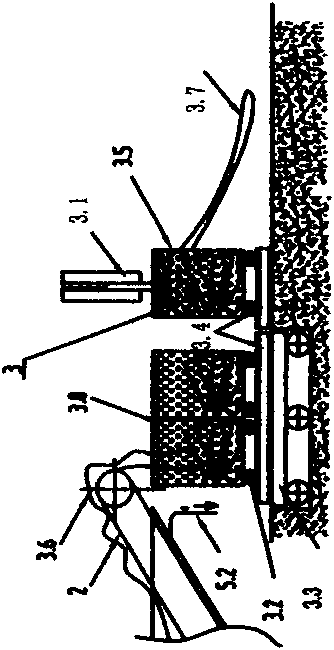

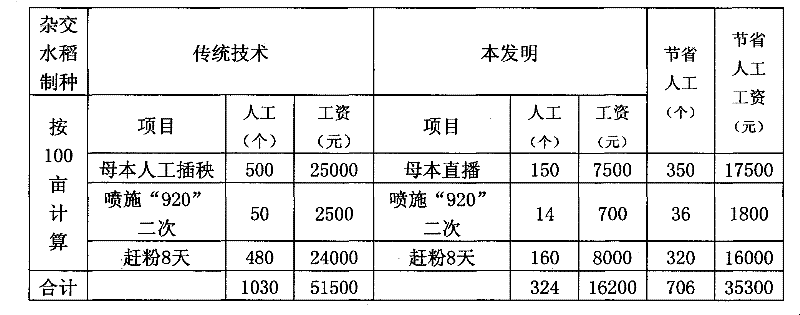

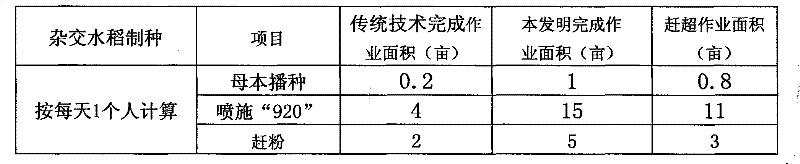

Seed production method of hybrid rice

ActiveCN101828523AImprove seed productionReduce spendingPlant genotype modificationRice cultivationPollenInsect pest

The invention discloses a seed production method of hybrid rice, which comprises the following steps of: (1) sowing of seeds and culture of seedlings: determining the sowing time according to the sowing periods of a male parent and a female parent to enable the flowering periods of the male parent and the female parent to be synchronized; (2) field management: carrying out water draining and field drying management based on shallow water mainly, covering the water in time after field drying to prevent and eliminate plant diseases and insect pests, and spraying '920' with power-operated spraying and dusting equipment to expel male parent pollen; (3) impurity prevention and preservation of pure state: ensuring that no sticky rice exists in the range of 200 meters beyond a seed production region and only the male parents of the seed production combination can be planted in the range of 20 meters beyond the seed production region, and killing off abnormal plants before flowering of cereal crops and loosing of powder to ensure the seed purity; and (4) harvesting and storing: cutting off the male parents in the seed farm to ensure that no male parent exists in the seed farm, and clearing a harvesting machine in the processes of harvesting and going to the field to ensure that no other seeds and impurities exist in the harvesting machine. The invention has the characteristics of high working efficiency, less labor demands, low cost, high purity, high quality, high yield and the like.

Owner:四川得月科技种业有限公司

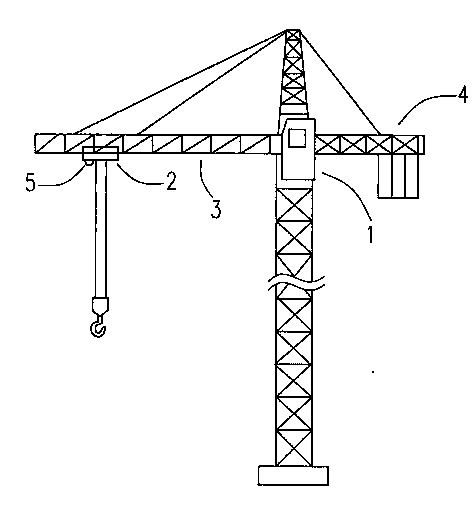

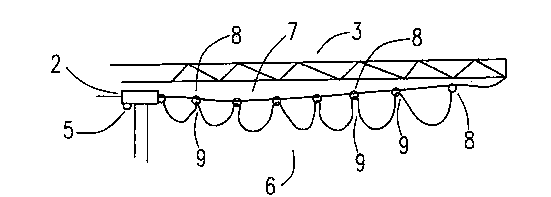

Tower crane operation video monitoring system

InactiveCN103950839AImprove work efficiencyDecrease productivitySafety gearVideo monitoringDisplay device

The invention discloses a tower crane operation video monitoring system. The tower crane operation video monitoring system comprises a control chamber, a trolley, a crane arm and a balance arm. The tower crane operation video monitoring system is characterized in that the trolley is provided with a holder-type camera; the control chamber is provided with a holder control keyboard, a monitoring display and a hard disk video which are connected with the holder-type camera. The improvement is that the tower crane operation video monitoring system is connected by a cable arranged on a telescopic installation seat. The tower crane operation video monitoring system provided by the invention is high in safety coefficient, can save labor cost, improve the working efficiency of hoisting operation, has stored video resources if accidents happen, also improves the operation mode of drivers, and the drivers can directly observe the monitoring display to master the running situation of a hopper.

Owner:兰天

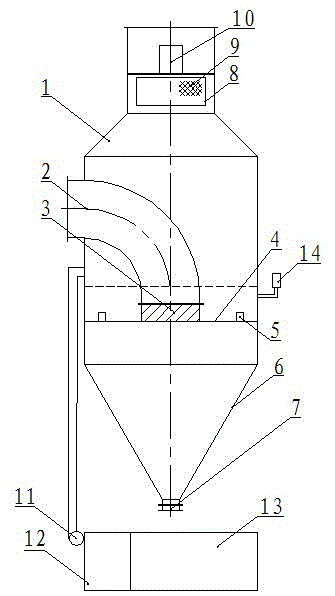

Efficient wet type dust collection and desulfuration integrated tower

InactiveCN103055678ARealize fully automated operationSave human effortUsing liquid separation agentAlkaline waterHigh humidity

The invention provides an efficient wet dust type collection and desulfuration integrated tower. The efficient wet type dust collection and desulfuration integrated tower comprises a barrel body, an air inlet pipe, a turbine, a differential plate, an ultrasonic vibrator, an ash settling bucket, an automatic ash discharging valve, a filler barrel, a filler, a high-temperature high-humidity motor, a water pump, an alkaline water tank and a drying tank; the high-temperature high-humidity motor is arranged above the barrel body, and the filler barrel in which the filler is filled is arranged below the high-temperature high-humidity motor; the differential plate is arranged in the barrel body; the turbine is arrange in the middle of the differential plate; one end of the air inlet pipe is connected with the turbine while the other end of the air inlet pipe extends out of the barrel body; the ultrasonic vibrator is arranged on the differential plate; the ash settling bucket is placed below the differential plate; the automatic ash discharging valve is arranged below the ash settling bucket; the drying tank is placed below the automatic discharging valve; the alkaline water tank is placed on one side of the drying tank; the water pump connected with the barrel body through a pipeline is arranged outside the alkaline water tank; and a water level controller is arranged in the middle of the barrel body. The efficient wet dust collection and desulfuration integrated tower can realize full-automatic operation, so that the manpower is saved; no wastewater is drained, and thus no secondary pollution is brought; and equipment is small in size.

Owner:ZUNYI CITY GUI KE TECH

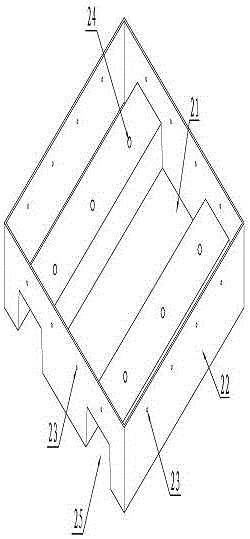

Livestock raising device capable of forming ecological cycle

ActiveCN110367126AIncrease grass yield and stocking capacityIncrease profitClimate change adaptationAnimal feeding devicesEconomic benefitsEngineering

A livestock raising device capable of forming an ecological cycle comprises a raising chamber or a plurality of raising chambers arrayed in a line. A crawler-type or a wheeltrack-type travelling mechanism and a hydraulic lifting mechanism are arranged in each raising chamber. Each raising chamber comprises a bottom plate and a ceiling, which are fixedly connected through a triangular steel cage frame. An excrement and urine drainage hole is formed in each bottom plate. The livestock raising device has the advantages that environment pollution caused by overflow of excrement and urine left by animals on grassland is avoided, the excrement and urine of the animals are turned into green forage for the animals, manual forage feeding is remarkably reduced, the raising cost is lowered, and economic benefits for raising are increased; manual raising is changed into mechanical raising, labor is remarkably reduced, and labor cost is saved; mechanical operation is changed into automation management, and accordingly, conventional animal husbandry is turned into modern animal husbandry.

Owner:TARIM UNIV

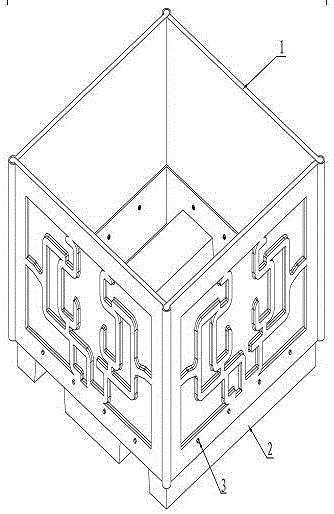

Split combined type flowerpot

InactiveCN106718220AFacilitate industrial mass productionIncrease production capacityReceptacle cultivationPalletFlowerpot

A split combined type flowerpot comprises side plates and a flowerpot pallet. The side plate comprises joining notches, a plate body and joining convex bodies; the joining notches and the joining convex bodies are arranged at two ends of the plate body and the joining convex bodies and the joining notches can be interlocked; the flowerpot pallet comprises a pallet bottom and a pallet side plate, wherein the pallet is enclosed by the pallet side plate; all side plates are connected to form a flowerpot barrel body by means of the interlocking connection mode between the joining convex bodies and the joining notches; the flowerpot barrel body and the flowerpot pallet are fixed and integrated. The flowerpot is designed into an assembled structure of a barrel body which is formed by interlocked side plates, an independent flowerpot pallet and connecting bolts, wherein the side plates and the flowerpot pallet are compressing parts which have enough intensity and anticorrosion performance; industrialization production is realized; the flowerpots are packaged and transported by components and are assembled in site; the production efficiency is 20 times of the artificial method and the production cost is lowered by 50% to 70%.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

Hot melt adhesive for shoe material, preparation method, shoe material applying hot melt adhesive and shoe material manufacturing method

PendingCN111154447ASimple processReduce defective ratePolyureas/polyurethane adhesivesMacromolecular adhesive additivesThermoplastic polyurethaneHot melt

The invention discloses a hot melt adhesive for a shoe material, a preparation method, the shoe material applying the hot melt adhesive and a shoe material manufacturing method. The hot melt adhesivefor the shoe material is prepared from the following components in parts by weight: 80 to 90 parts of thermoplastic polyurethane elastomer and 10 to 20 parts of ethylene-ethyl acetate copolymer. The preparation method of the hot melt adhesive for the shoe material comprises the following steps: weighing the components according to the proportion of the hot melt adhesive for the shoe material; stirring the components at normal temperature; and heating the stirred mixture to 160-170 DEG C. The components of the hot melt adhesive for the shoe material are environmentally friendly, and the hot melt adhesive does not contain formaldehyde, azo, lead, phthalate and other substances and reaches related standards of new European standards. According to the manufacturing method of the shoe material,hot pressing and stitching are not needed, the process is simple, the defective rate is low, the production cost including manual salary, electric charge and the like is greatly reduced, and the production efficiency is high.

Owner:晋江兴鸿鞋材有限公司

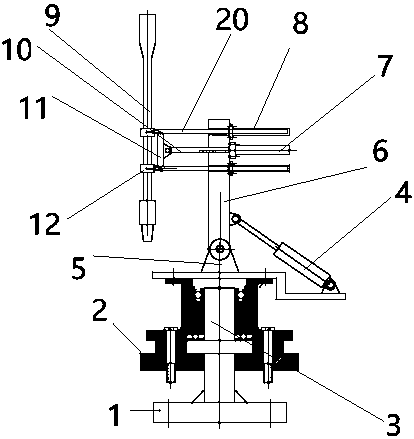

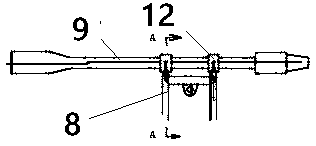

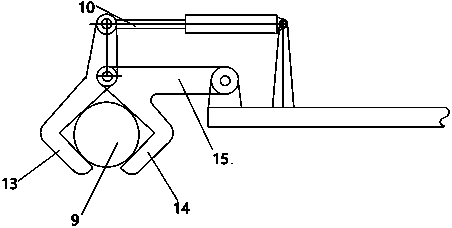

Vehicle-mounted top drive drilling machine and using method thereof

The invention relates to the field of machinery, in particular to a vehicle-mounted top drive drilling machine and a using method thereof. According to the scheme, a skid-mounted vehicle-mounted drivesystem, an electric reduction machine driven traveling system, a slideway replacement drilling tower mechanism, a top drive mechanism, a drill rod grabbing and displacement adjusting mechanism, namely an automatic feeding mechanism, and connection between a top driver and tracks are included. The structure is simple, the manufacturing cost is low, and the practicability is strong. An engine is changed into a turbo-generator set, and natural gas is cheaper than diesel oil by 30% as fuel. Automation and mechanical arms replace traditional labor, and labor wages can be saved by 50%. The removalis convenient, the automation degree is high, and the operation cost is lower than that of a traditional drilling machine.

Owner:李银佩

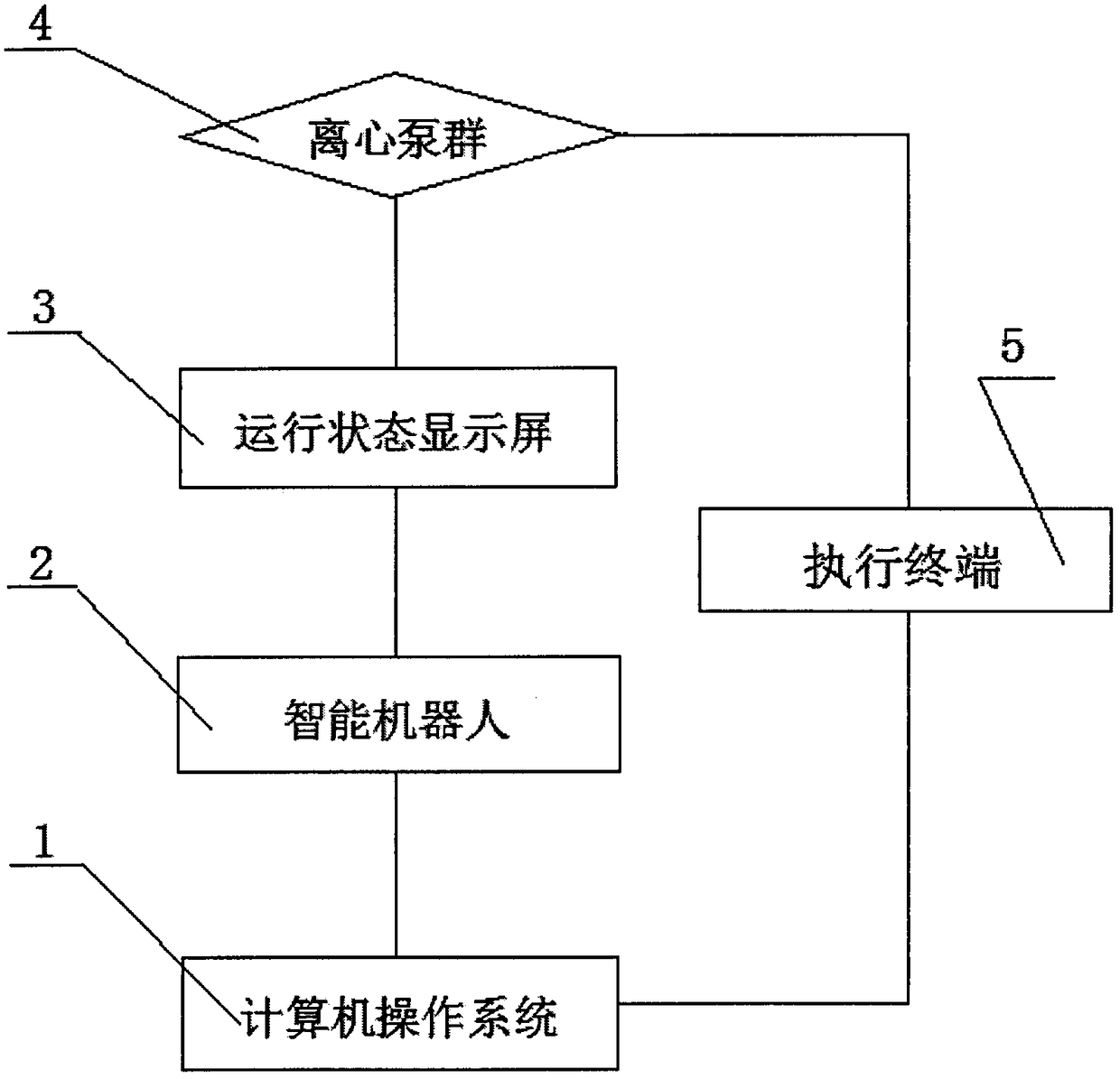

Centrifugal pump group routing inspection intelligent robot and operation method thereof

PendingCN109227548AReduce human resource costsSave labor wagesProgramme-controlled manipulatorOperational systemState parameter

The invention relates to a centrifugal pump group routing inspection intelligent robot, which consists of a centrifugal pump group, an operation state display screen, an intelligent robot, a computeroperation system and an execution terminal, wherein the operation state parameters of each centrifugal pump in the centrifugal pump group comprises a pressure at the outlet of the pump, a running power of the pump, a temperature of a bearing, a water content of lubricating oil, a leakage condition of a shaft seal, noise and the like, the parameters are collected through sensors and are intensivelydisplayed on the operation state display screen of the centrifugal pump in a form of codes; the intelligent robot reads and identifies the codes on the operation state display screen of the centrifugal pump and transmits the codes to a computer; the computer operation system provides treating advice after identifying and comparing, then the advice is transmitted to the execution terminal, the intelligent robot informs an attendant to confirm and executes normal operation, problematic operation, emergency parking switching and the like; a daily duty table is exported and printed by the intelligent robot. The device has the advantages of saving human resource cost, improving production safety rate, ensuring product quality, achieving unmanned production site and the like.

Owner:GUANGXI POLYTECHNIC VOCATIONAL & TECHN COLLEGE

A livestock raising device capable of realizing ecological cycle

ActiveCN110367126BIncrease grass yield and stocking capacityIncrease profitClimate change adaptationAnimal feeding devicesArtificial rearingCrop livestock

A livestock breeding device capable of realizing an ecological cycle, comprising one section or a multi-section feeding room arranged in a line, the feeding room is equipped with a crawler type or wheel-rail type walking mechanism, and a hydraulic lifting mechanism, and the feeding room includes a bottom plate and a ceiling through a triangular The steel cage frame is fixedly connected, and the excrement holes are set on the bottom plate. The animal excrement and urine will not spill over and pollute the environment when it is scattered on the grass. It realizes the conversion of animal excrement into green feed for feeding animals, greatly reducing artificial feeding and reducing The cost of feeding improves the economic benefits of feeding, realizes the transition from artificial feeding to mechanical feeding, greatly reduces labor costs, and saves labor wages. Transition from traditional animal husbandry to modern animal husbandry through mechanical operation and then transition to automated management.

Owner:TARIM UNIV

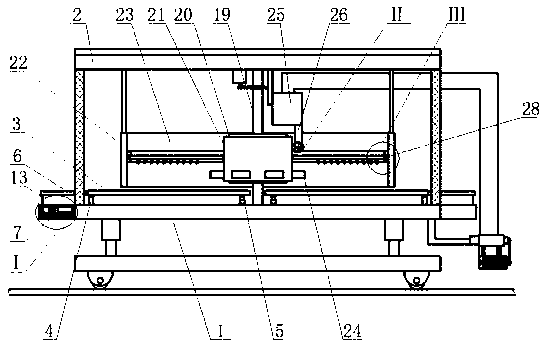

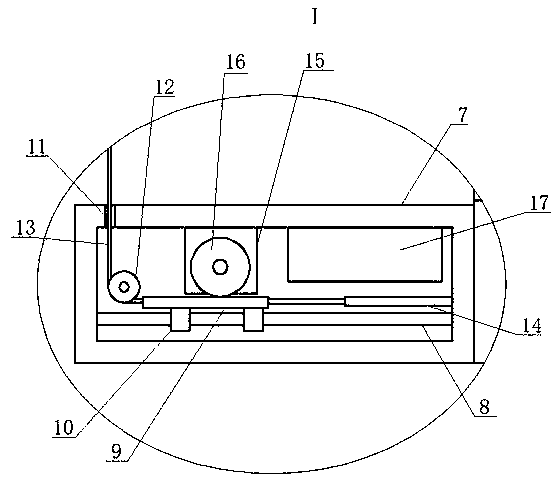

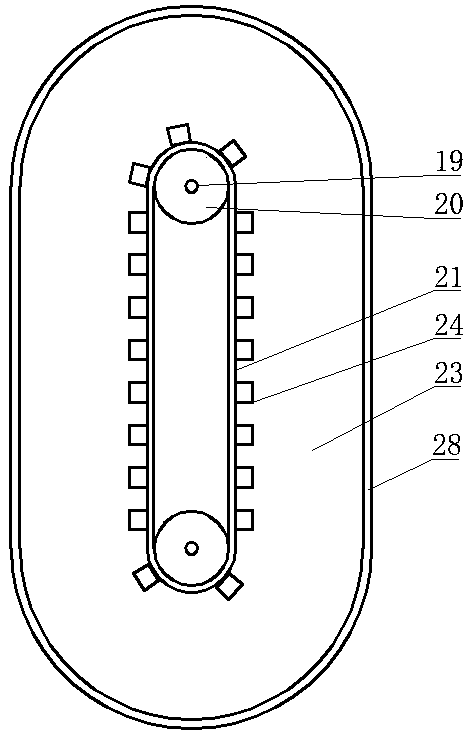

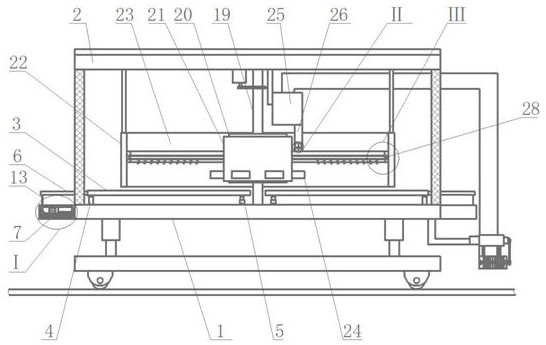

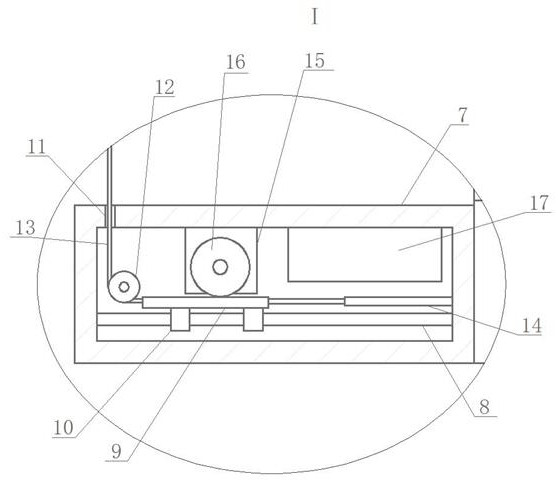

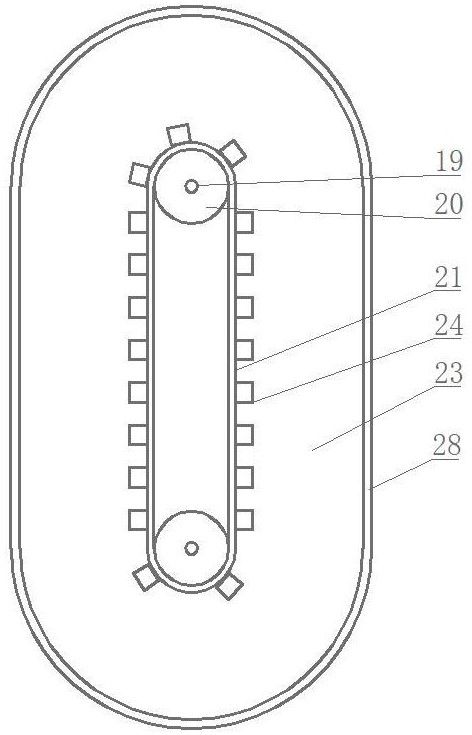

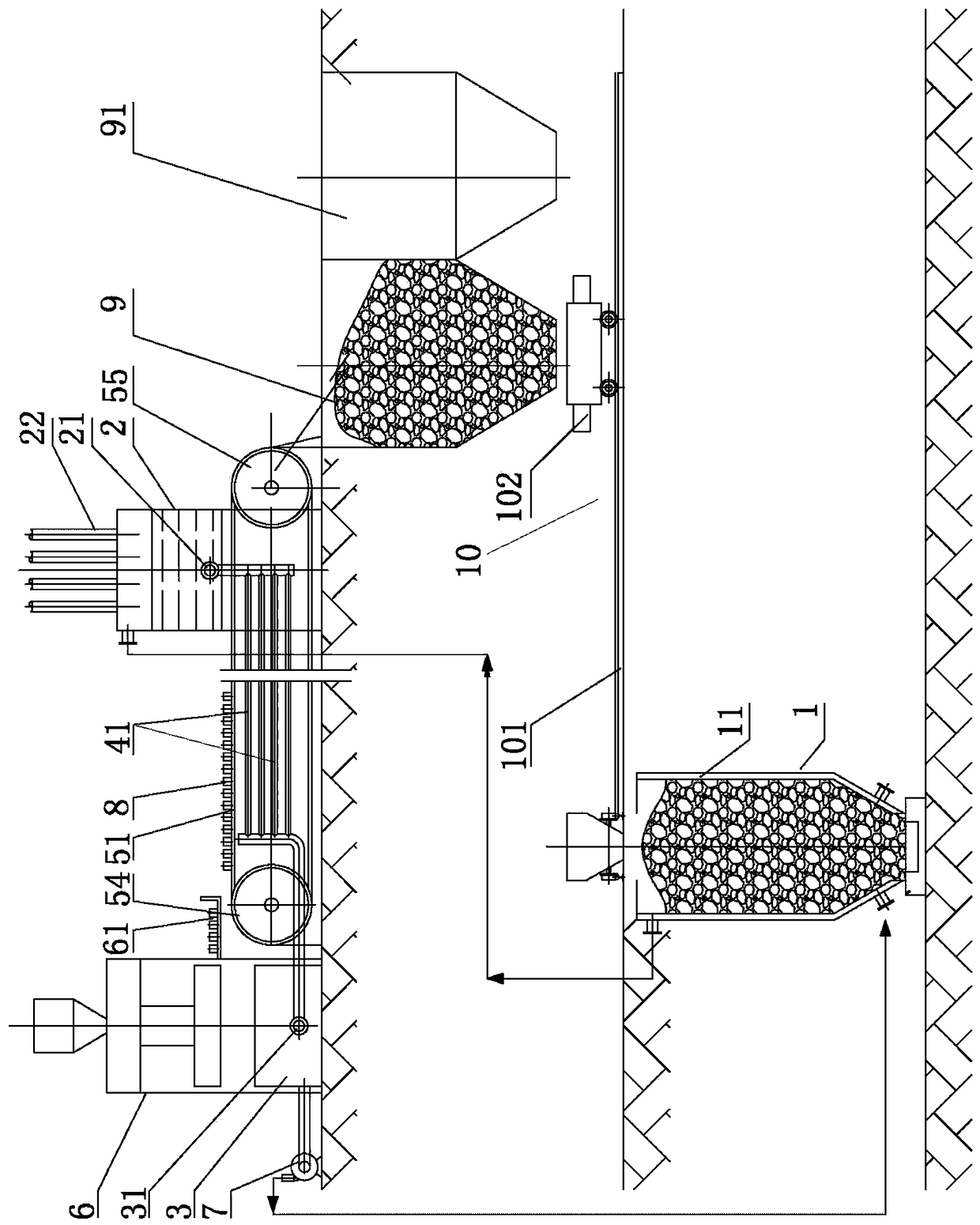

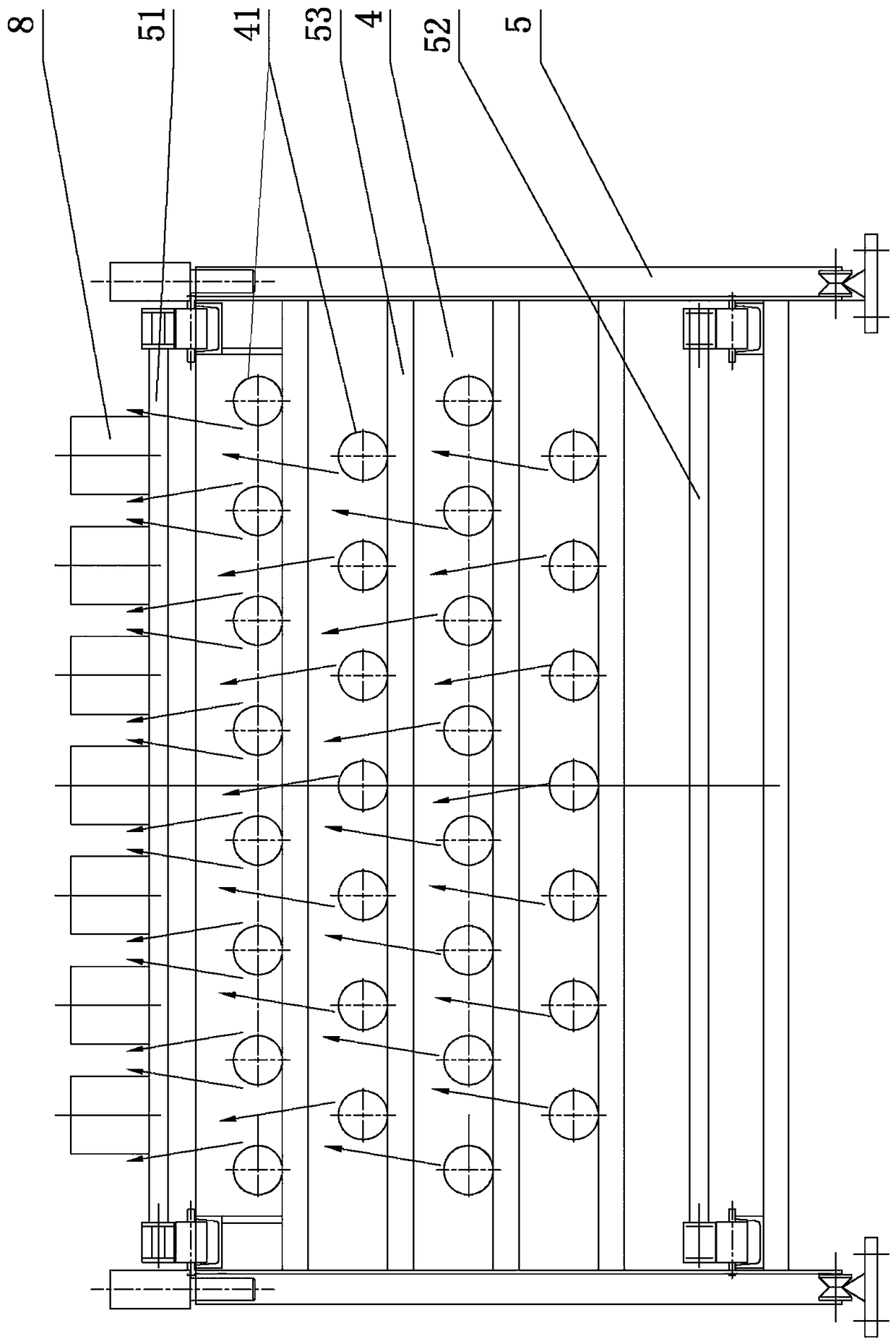

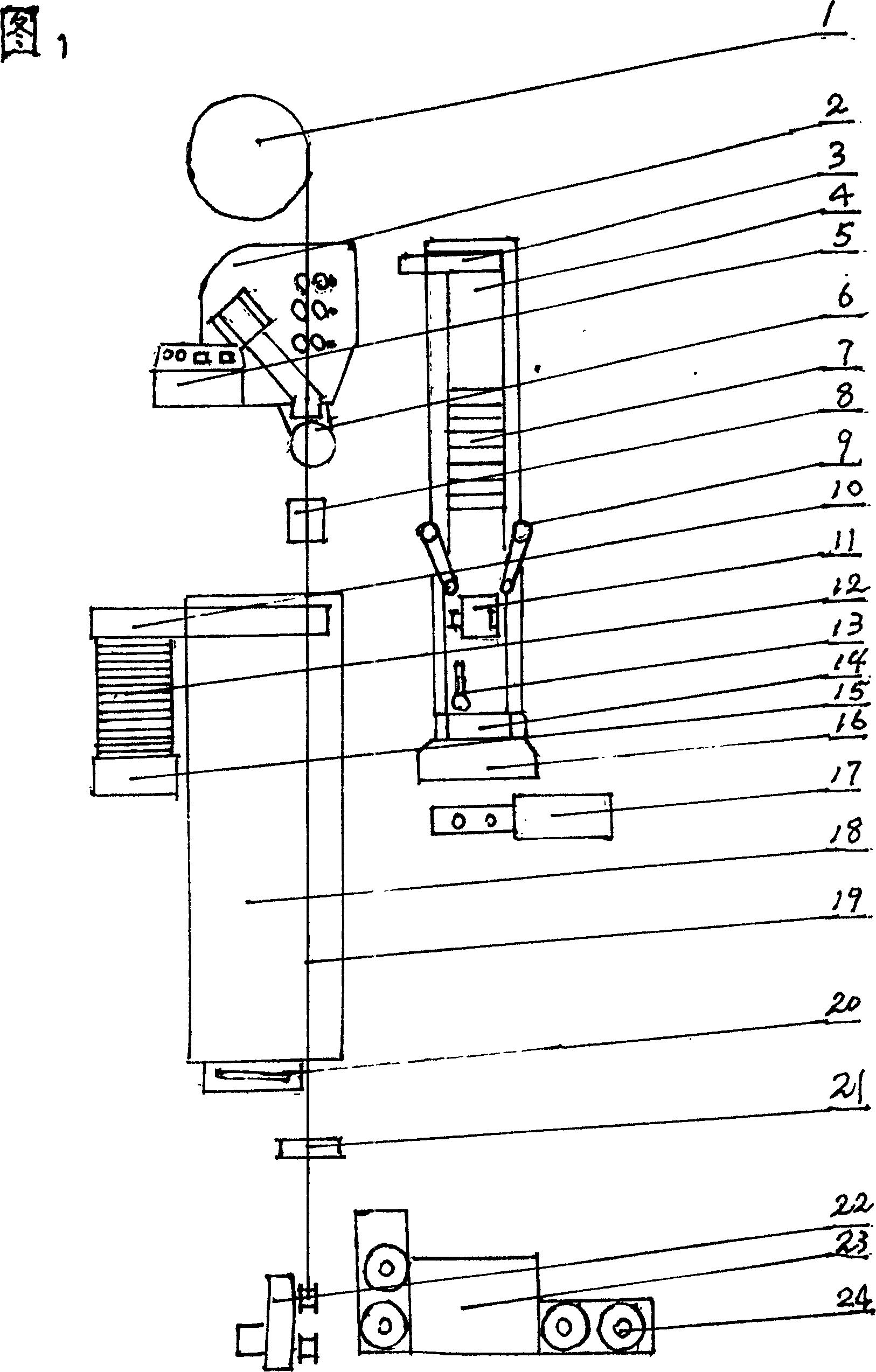

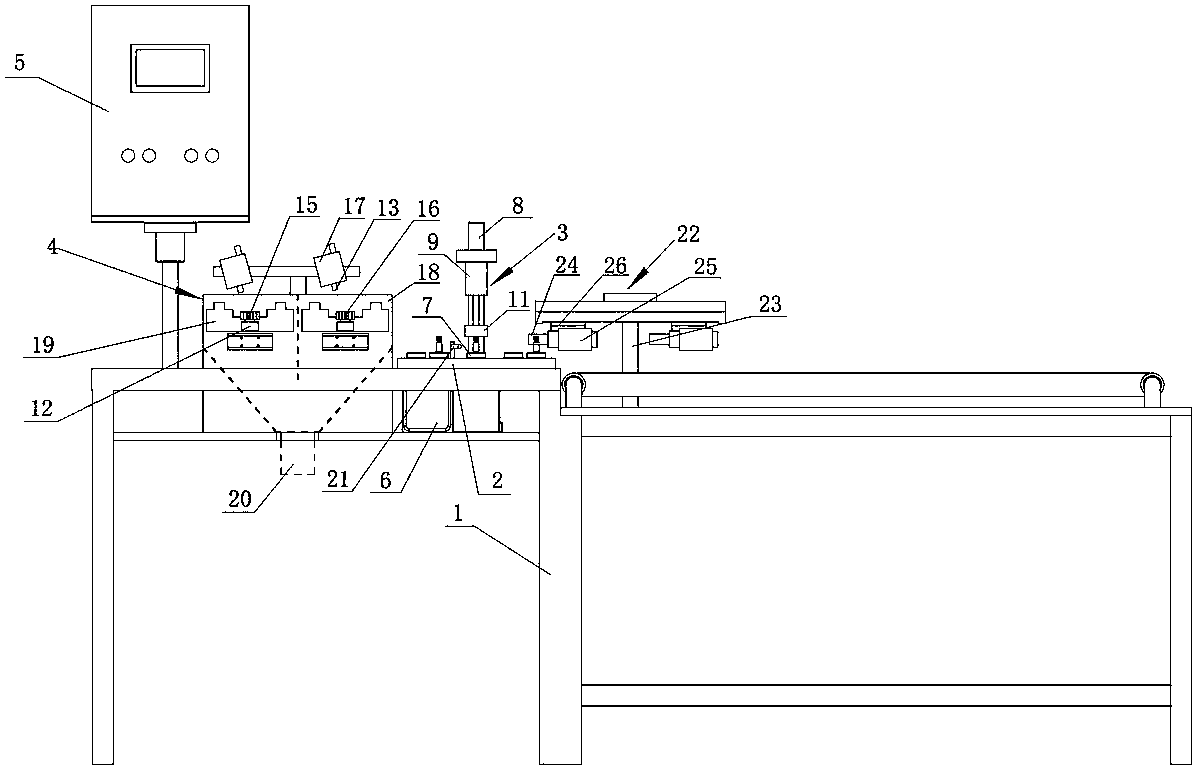

Method for circulating hot water though furnace body water jacket of blast furnace, drying to reduce water of briquetted furnace charge and automatically charging

InactiveCN108131956ASave labor wagesReduce occupancyDrying gas arrangementsCharge manipulationCold airWater flow

The invention discloses a method for circulating hot water through a furnace body water jacket of a blast furnace, drying to reduce water of briquetted furnace charge and automatically charging. A high-position hot water tank is arranged above the blast furnace for receiving high-temperature hot water circulated out from the furnace body water jacket of the blast furnace; high-temperature hot water flows to a low-position water tank after passing through a hot water tube arranged in the a long-chain-row conveyor; cold air outside a hot water tube wall is heated to form ascending hot air flow for continuously heating conveying wet briquetting materials, so that water is dried and reduced, and then is conveyed to a storage hopper arranged under the long-chain-row conveyor; heat-exchanged andcooled hot water in a hot water tube enters the low-position water tank to store and is pumped to the furnace body water jacket of the blast furnace for circulatory heating; and a charging system isarranged between the storage hopper and the blast furnace, so that automatic conveying and charging of the blast furnace is realized. In this way, natural circulating air is heated by the furnace bodywater jacket of the blast furnace, and water of briquetted furnace charge is reduced by drying, strength of briquetted furnace charge is improved, long-distance conveying is directly realized, the blast furnace is automatically charged, and production cost is reduced.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

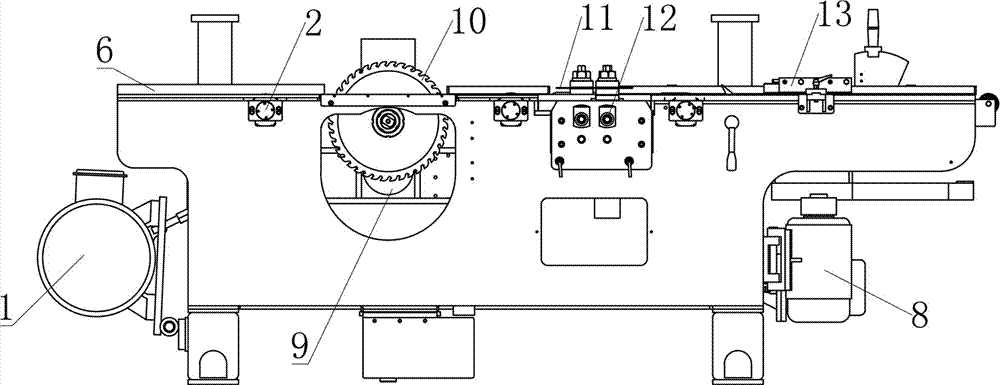

Three-axis sectioning multi-blade saw

The invention belongs to the technical field of wood machines, and particularly relates to a three-axis sectioning multi-blade saw capable of reducing wastes. The saw comprises a machine body, a work table, a control table, a main motor, a saw shaft subassembly and a lifting motor of the saw shaft subassembly, and the saw is characterized in that a plurality of round feeding wheels and a plurality of toothed feeding wheels are arranged on the work table, the toothed feeding wheels are mounted on a lifting cross beam, a sawing subassembly is arranged on one side of the saw shaft subassembly, the sawing subassembly comprises a vertical shaft sawing part and a sawing power motor driving the vertical shaft saw to rotate, and wood is sequentially fed to the sawing subassembly to be sawn and the saw shaft subassembly to be sawn into pieces through the toothed feeding wheels and the round feeding wheels on the work table. Through the device, side skin materials on the two sides can be directly used so as to improve the wood yield, two machines are combined into one, equipment purchasing cost is reduced, the manual wages are reduced, occupied space is small, power of a motor is small, under the condition that a customer has no side skins, two sawing parts can get off, and serve as a common multi-blade saw, and one machine has multiple purposes.

Owner:临海市华洲机械有限公司

Intensified smelting method of titanium slag in a blast furnace

ActiveCN111635970BImprove liquidityImprove stabilityBlast furnace detailsSiliconIndustrial engineering

The invention relates to an intensified smelting method of titanium slag in a blast furnace, comprising the following steps: batching, smelting, smelting parameter setting, and conventional slag and iron tapping. The furnace hearth of the invention is in good working condition, the uniformity and activity are significantly improved, a new state of molten iron with low silicon and high physical heat is obtained, the low silicon range and deviation value of molten iron are further controlled, and the fluidity and stability of slag and iron are improved. Realize blast furnace utilization factor >3.65t / (m 3 .d) The long-term stable smelting of low-silicon and low-sulfur qualified pig iron can significantly reduce the fixed asset allocation, financial management, labor wages, electricity costs, etc. of unit pig iron by significantly increasing the annual output of a single blast furnace, thereby reducing the cost of smelting and preparing per ton of iron.

Owner:WUKUN STEEL +1

Intensified smelting method for titanium slag in blast furnace

ActiveCN111635970AShorten the smelting cycleImprove liquidityBlast furnace detailsBlast furnaceTitanium slag

The invention relates to an intensified smelting method for titanium slag in a blast furnace. The method comprises the following steps of proportioning, smelting, smelting parameter setting and conventional slag tapping and iron tapping. The working state of a hearth is good, the uniformity and the activity degree are remarkably improved, a low-silicon and high-physical-heat molten iron new stateis obtained, the low-silicon range and the deviation value of the molten iron are further controlled, the fluidity and the stability of the slag iron are improved, and the long-period stable smeltingof low-silicon and low-sulfur qualified pig iron with the utilization coefficient of the blast furnace of 3.65 t / (m<3>.d) is realized. By remarkably improving the annual output of the single blast furnace, the allocation of fixed assets of unit pig iron, financial management, labor wages, electric charges and the like are remarkably reduced, so that the smelting preparation cost of ton iron is reduced.

Owner:WUKUN STEEL +1

Method for continuously manufacturing electric welding rod and short welding rod of nanometer coating compatibly

InactiveCN100364714CLow priceImprove welding qualityWelding/cutting media/materialsSoldering mediaProduction lineEngineering

A technology for manufacturing both short welding electrodes and the coiled continuous welding electrode, which are coated by a nano-class coated layer features that its mechanical apparatuses are arranged to become a program-controlled parallel small production line.

Owner:高忠民

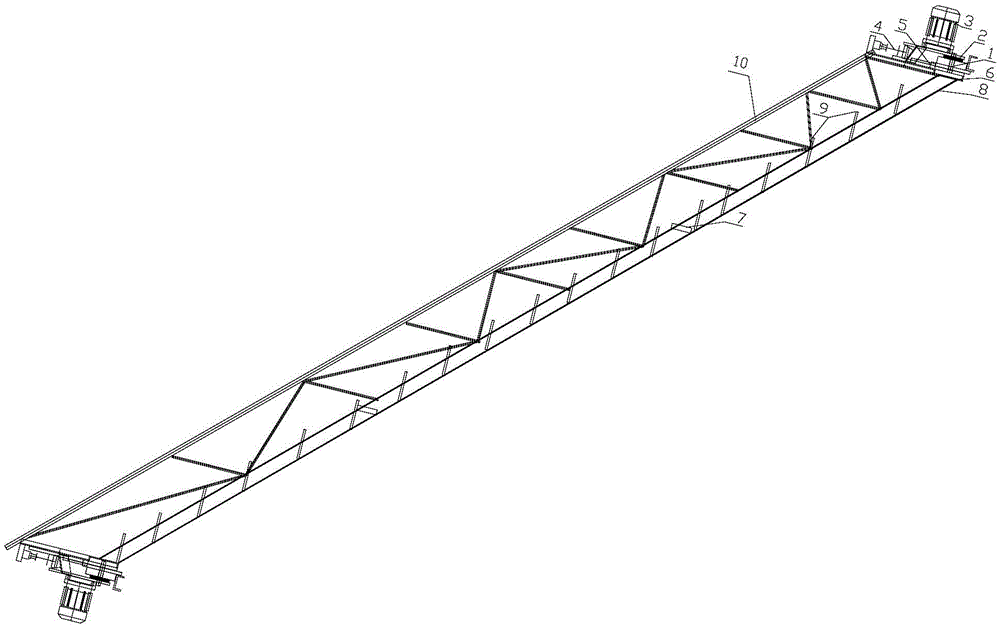

A roadbed slope protection truss trolley and its construction method

The invention relates to a roadbed slope protection truss trolley and a construction method. The construction method includes steps of (1), preparing for construction and mounting and configuring gears, rollers, motors, jacks, connecting section steel and H-shaped section steel socket systems; (2), mounting fixing frames at positions where formworks need to be fixed; (3), mounting upper and lower ladder stands at two side edges of a truss; (4), arranging cables along the direction of a roadbed line, connecting one end of each cable with the corresponding motor and connecting the other end of each cable with a changeover switch; (5), adjusting the elevations of the formworks and the elevation of the truss under the control of handles of the jacks; (6), adjusting the traveling direction of the truss under the control of the changeover switches. The roadbed slope protection truss trolley and the construction method have the advantages that labor and materials can be saved, the roadbed slope protection truss trolley and the construction method are low in investment and wide in service range, the labor intensity of workers can be reduced, and maintenance can be facilitated.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

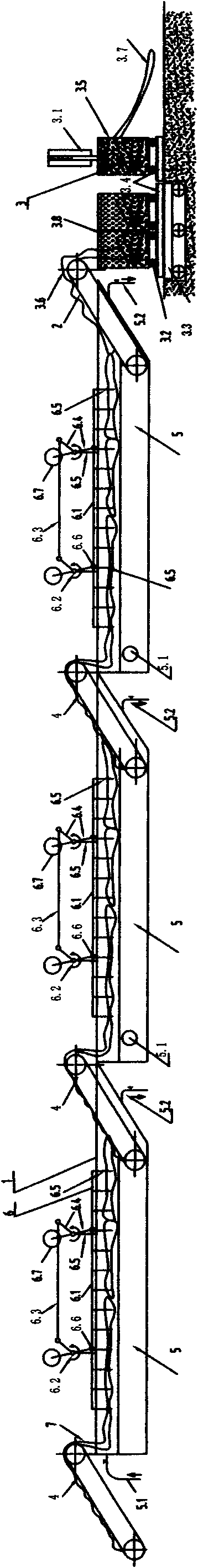

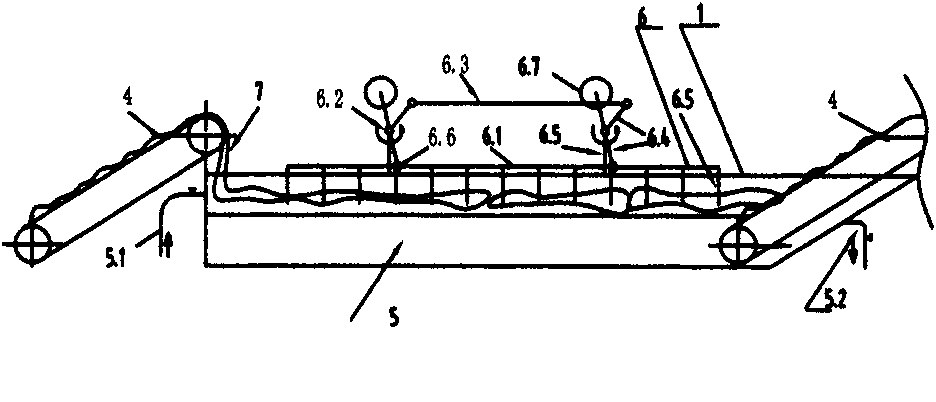

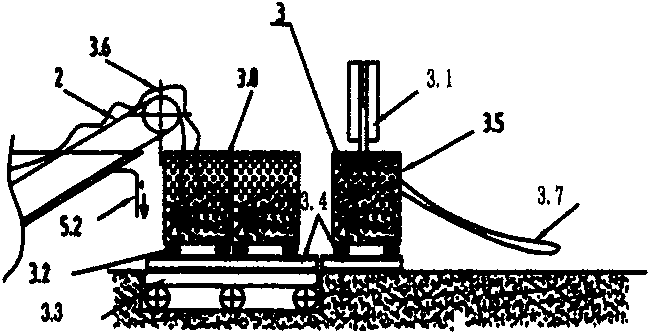

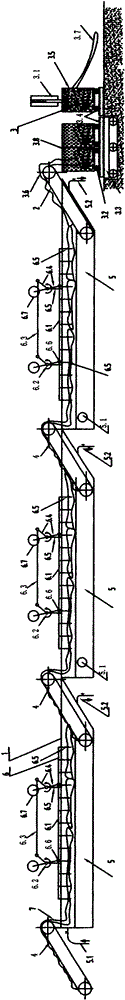

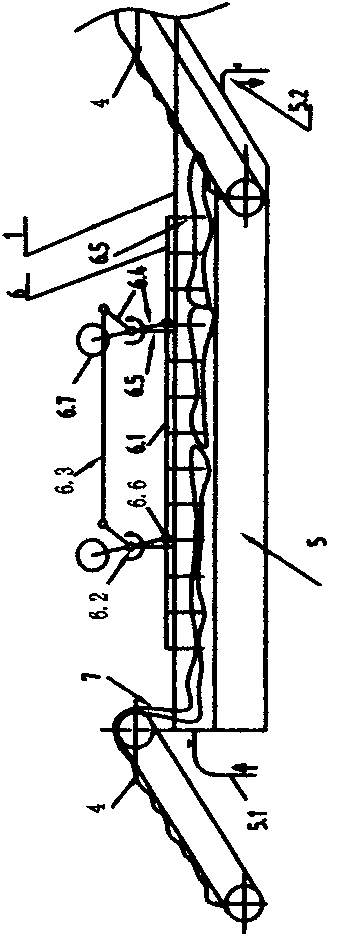

Ramie bast fiber washing and fiber pressing linkage device

InactiveCN102071475APrevent hoardingSolve the flaws of messing aroundVegetable materialState of artEngineering

The invention provides a ramie bast fiber washing and fiber pressing linkage device, relating to the field of a ramie production processing device. The device solves the disadvantages that washing machines and dehydrators in the prior art are low in output, bad in production efficiency, high in energy loss and not beneficial for environment protection. The linkage device comprises a ramie washing device, a ramie outlet curtain and a pressing device, wherein the ramie washing device is joined with the pressing device through the ramie outlet curtain. The device is simple in structure, convenient in operation, low in improved investment cost, high in output, energy loss saving, work saving and material saving; the device further washes the ramie thoroughly and does not lead to disorder; and the device is suitable for popularization and application.

Owner:HUNAN MINGXING FIBER

Ramie bast fiber washing and fiber drying linkage equipment

InactiveCN102071475BPrevent hoardingSolve the flaws of messing aroundVegetable materialHigh energyEngineering

A ramie bast fiber washing and fiber drying linkage equipment, which relates to the field of ramie production and processing equipment, solves the problems of low output, poor production efficiency and high energy consumption that are not conducive to environmental protection in the prior art using washing machines and dehydrating machines. It includes a hemp washing device, a hemp outlet curtain and a drying device, and the hemp washing device is connected with the drying device through the hemp outlet curtain. The invention has the advantages of simple structure, convenient operation, low transformation input cost, high output, energy saving, labor saving, material saving, hemp cleaning is thorough, and it is not easy to cause mess, and is suitable for popularization and application.

Owner:HUNAN MINGXING FIBER

Seed production method of hybrid rice

ActiveCN101828523BImprove seed productionReduce spendingPlant genotype modificationRice cultivationPollenInsect pest

The invention discloses a seed production method of hybrid rice, which comprises the following steps of: (1) sowing of seeds and culture of seedlings: determining the sowing time according to the sowing periods of a male parent and a female parent to enable the flowering periods of the male parent and the female parent to be synchronized; (2) field management: carrying out water draining and field drying management based on shallow water mainly, covering the water in time after field drying to prevent and eliminate plant diseases and insect pests, and spraying '920' with power-operated spraying and dusting equipment to expel male parent pollen; (3) impurity prevention and preservation of pure state: ensuring that no sticky rice exists in the range of 200 meters beyond a seed production region and only the male parents of the seed production combination can be planted in the range of 20 meters beyond the seed production region, and killing off abnormal plants before flowering of cerealcrops and loosing of powder to ensure the seed purity; and (4) harvesting and storing: cutting off the male parents in the seed farm to ensure that no male parent exists in the seed farm, and clearing a harvesting machine in the processes of harvesting and going to the field to ensure that no other seeds and impurities exist in the harvesting machine. The invention has the characteristics of highworking efficiency, less labor demands, low cost, high purity, high quality, high yield and the like.

Owner:四川得月科技种业有限公司

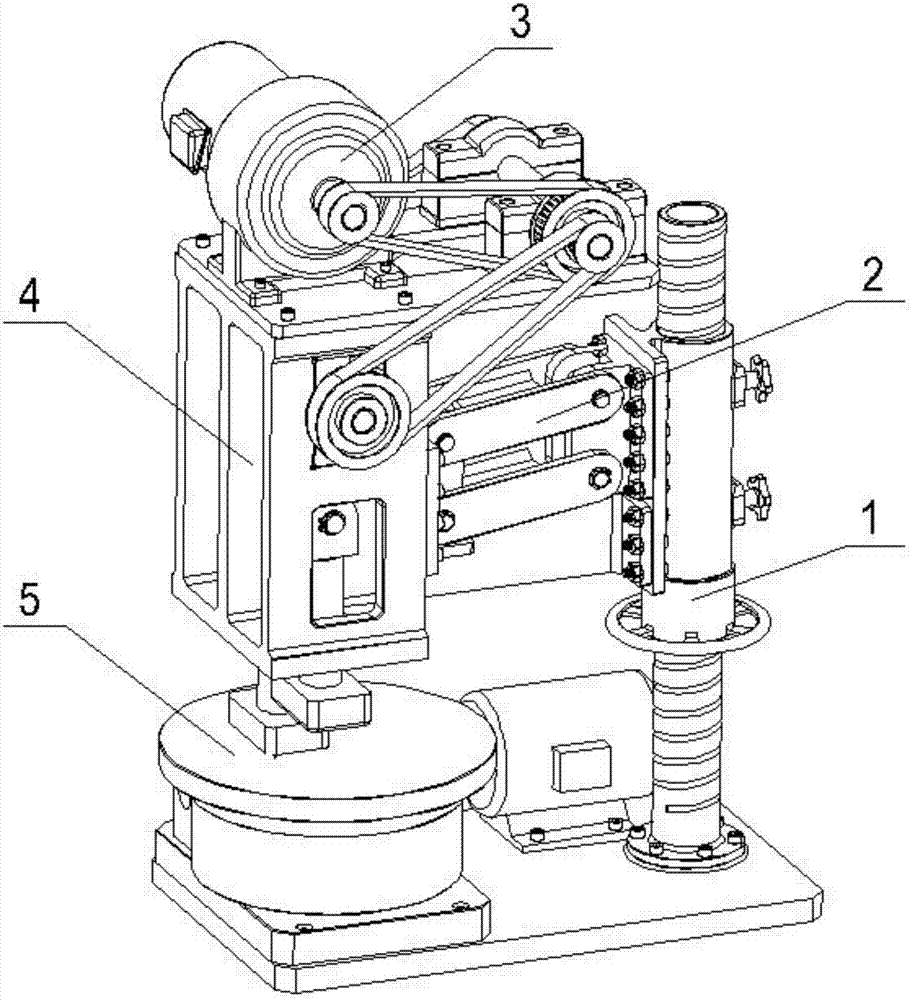

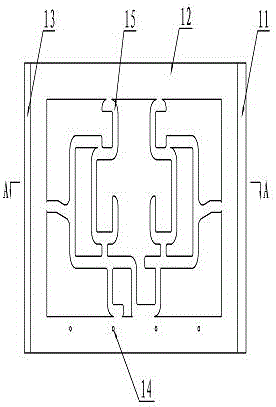

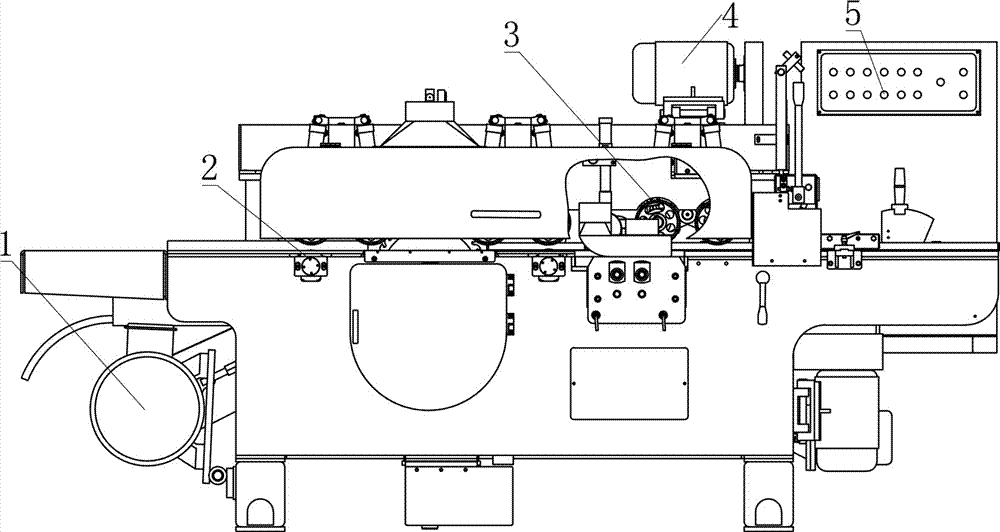

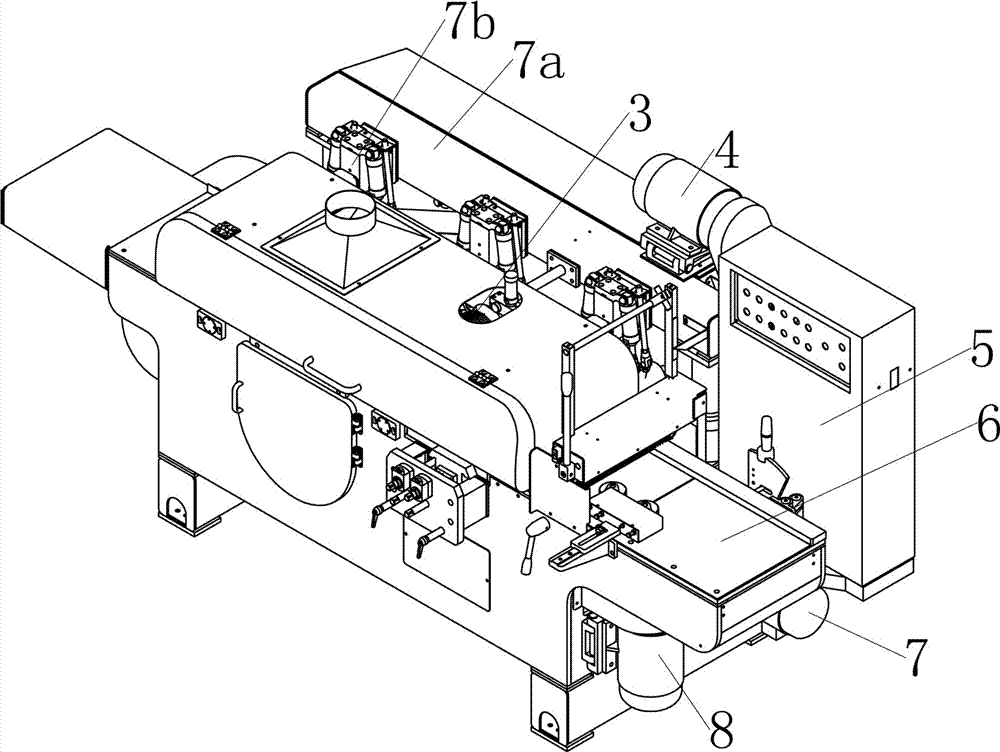

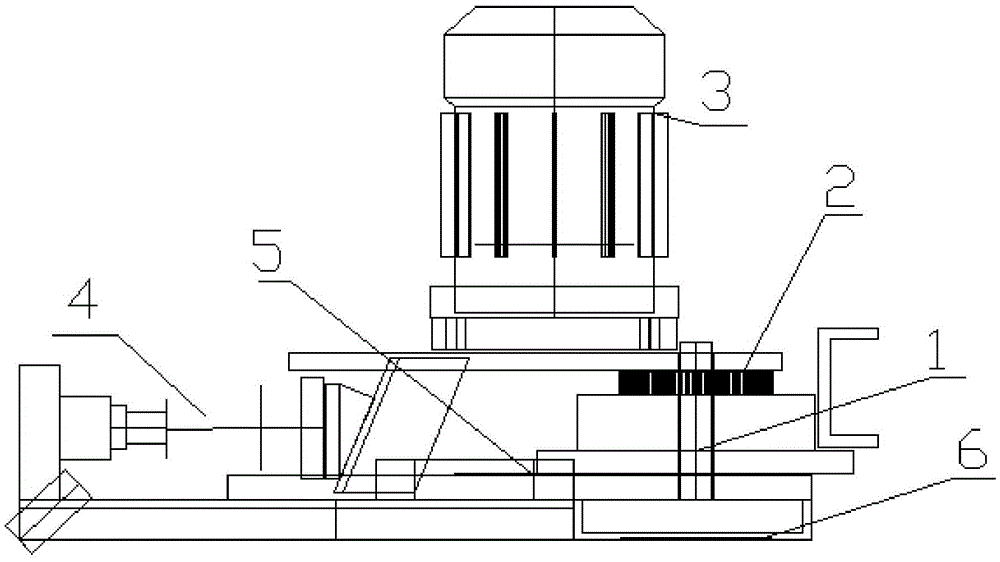

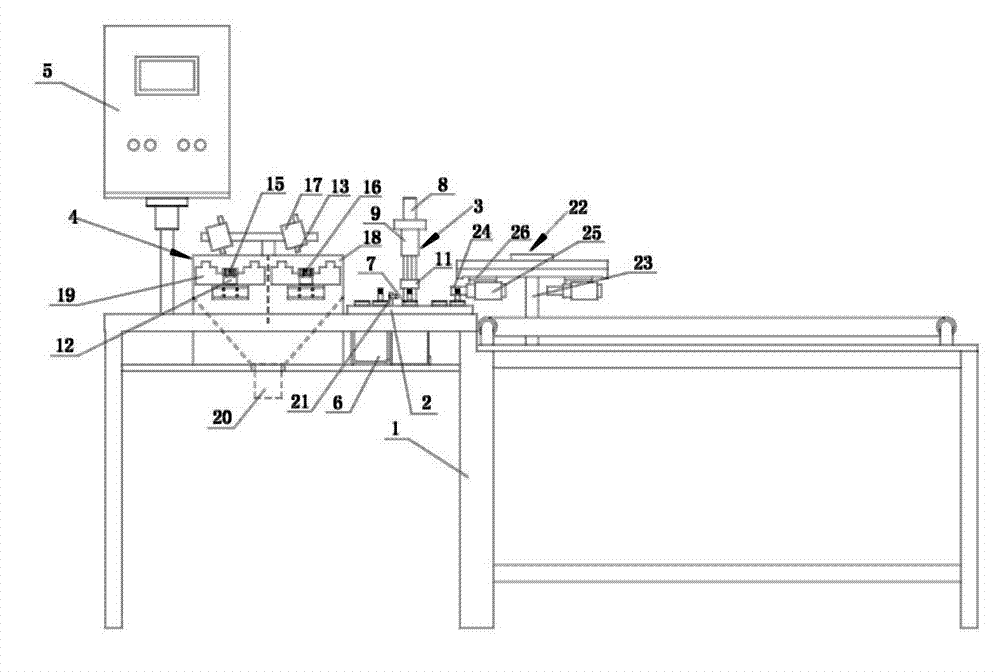

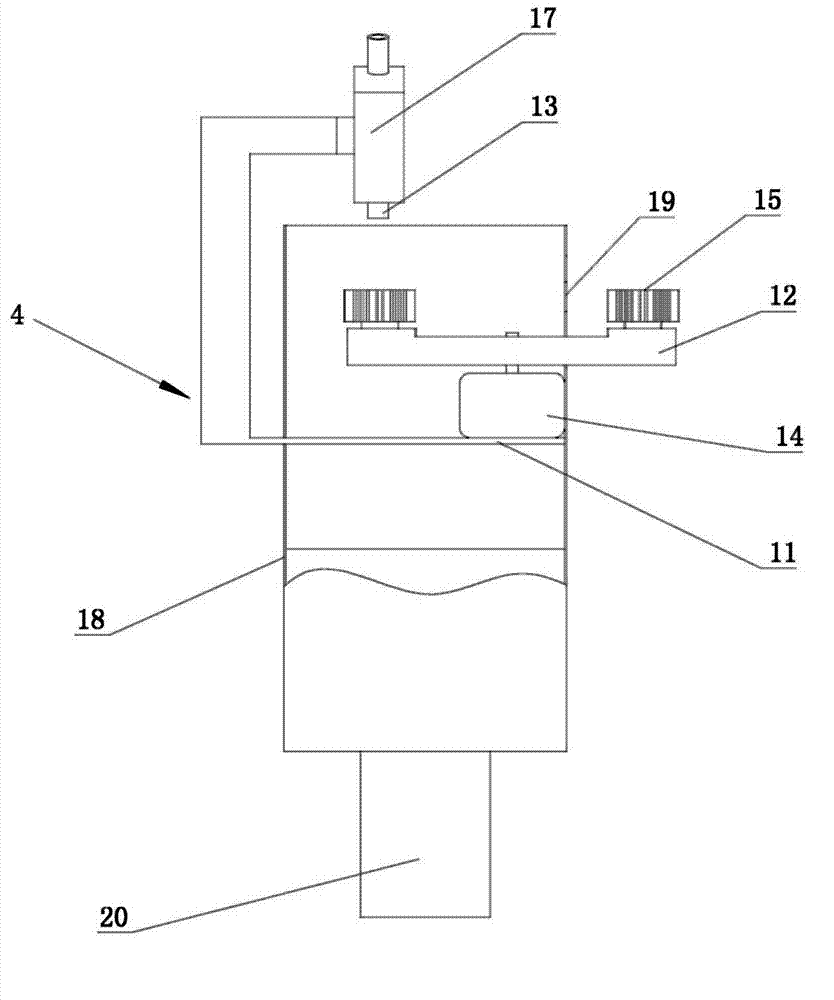

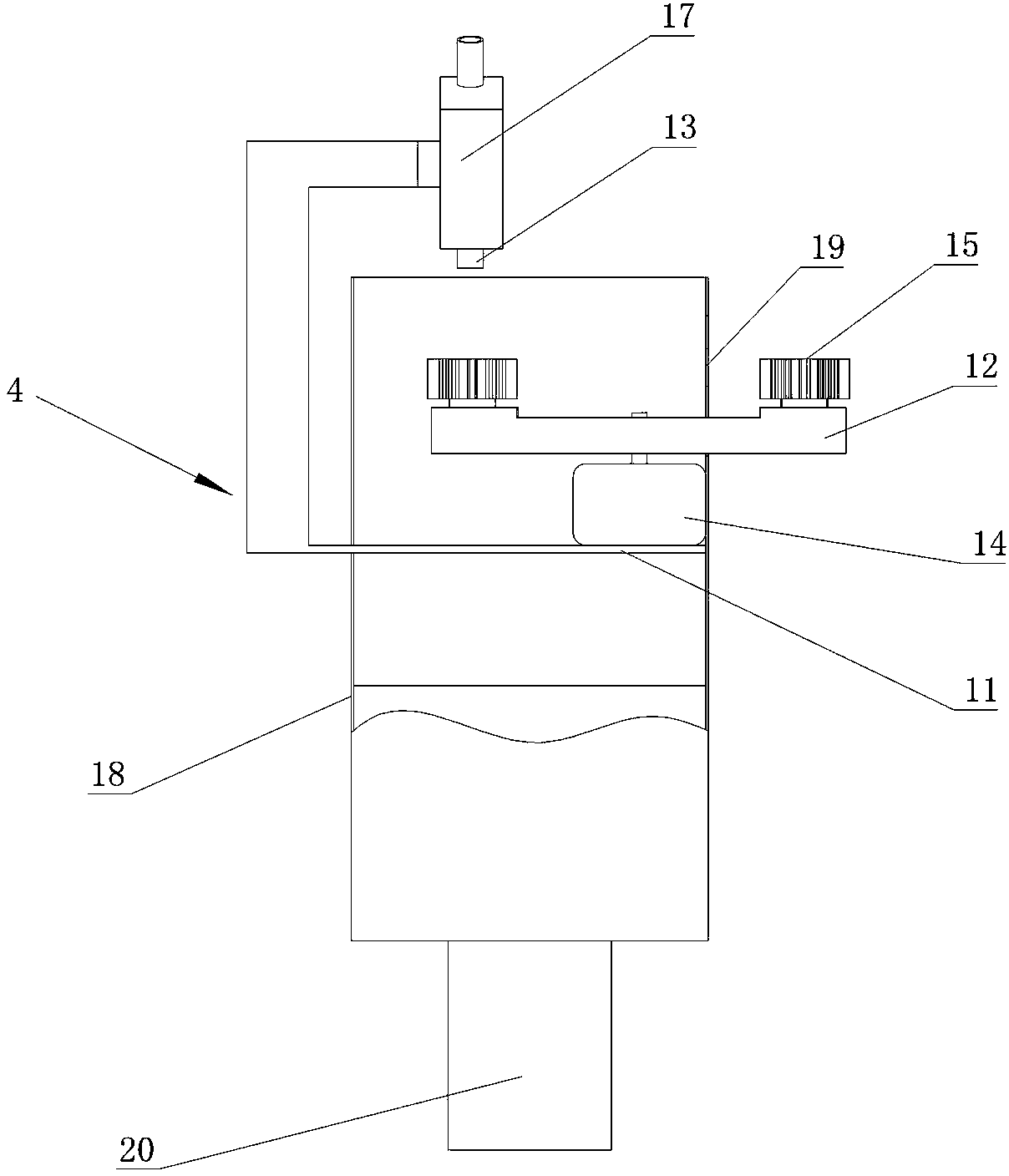

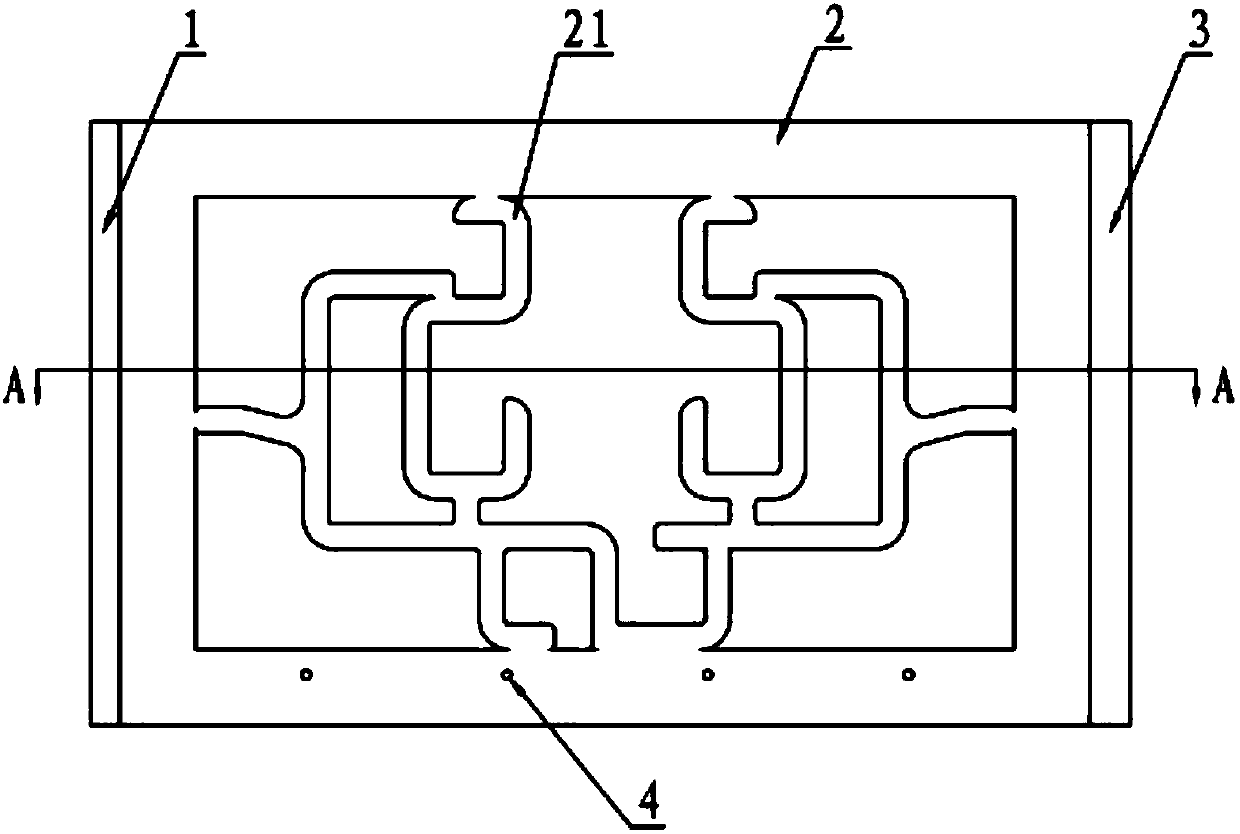

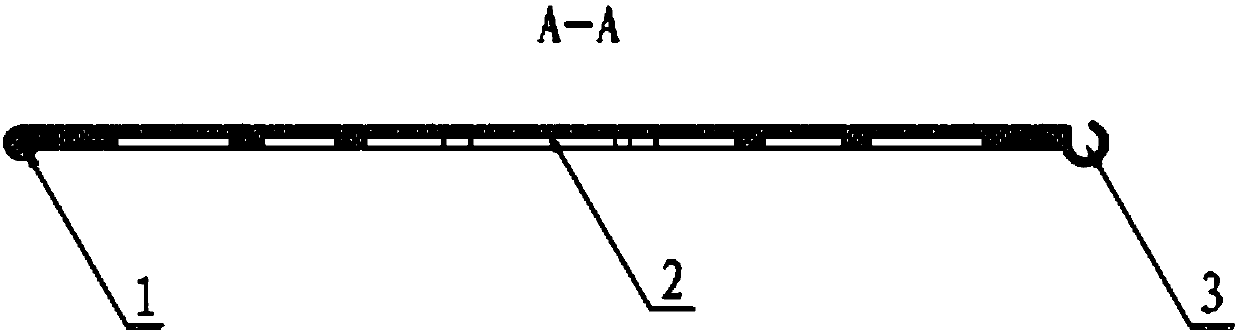

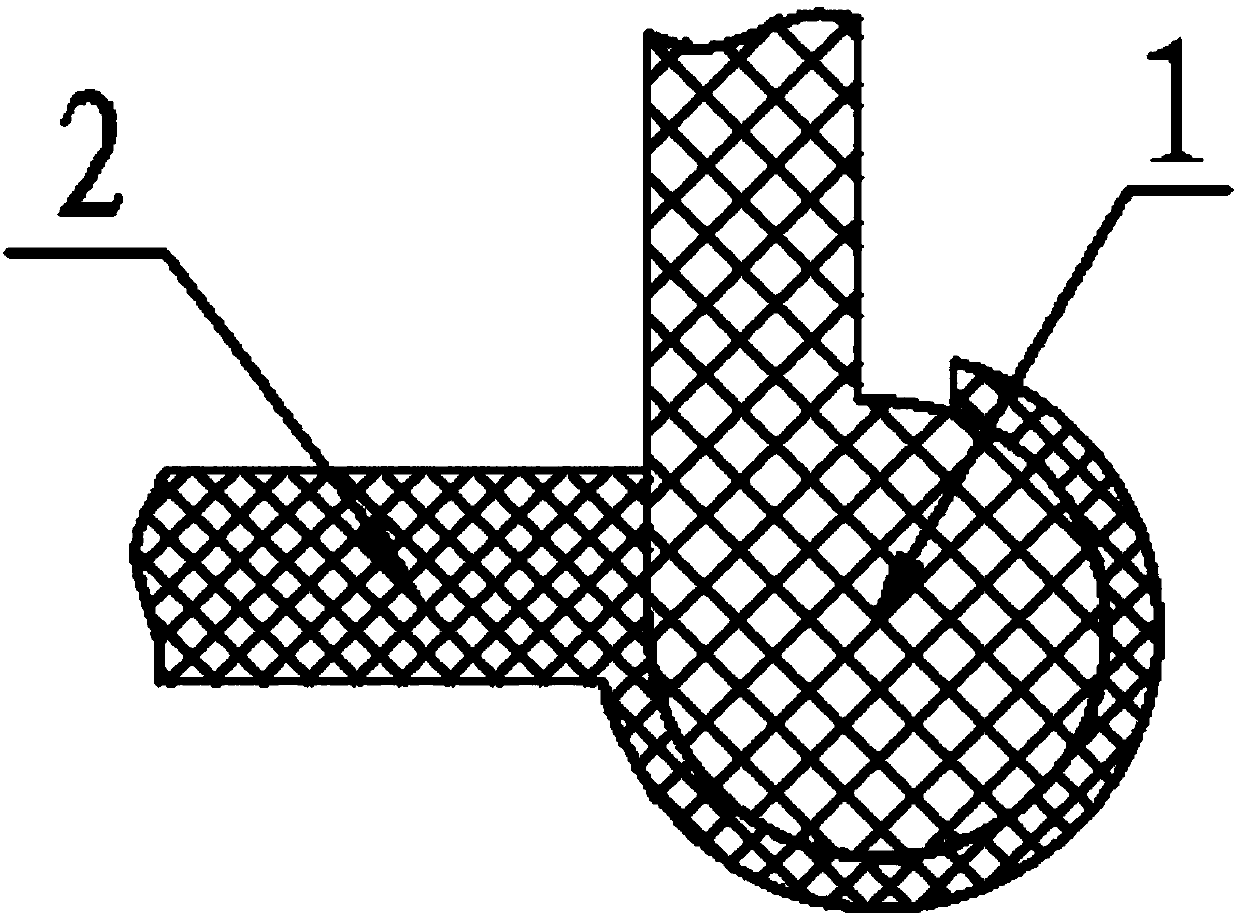

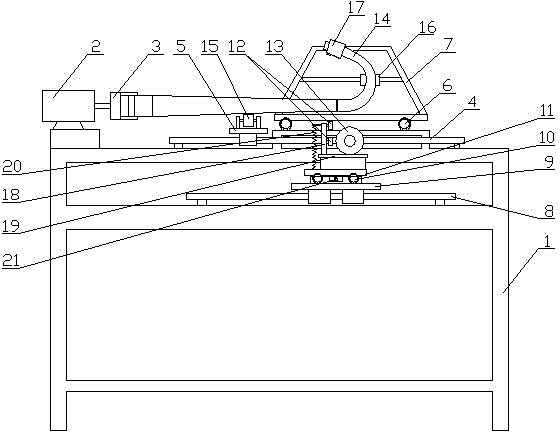

Automatic blowing and pressing machine for electromagnetic valves

ActiveCN102922259AReduce in quantityReduce energy consumptionMetal working apparatusEngineeringMechanical engineering

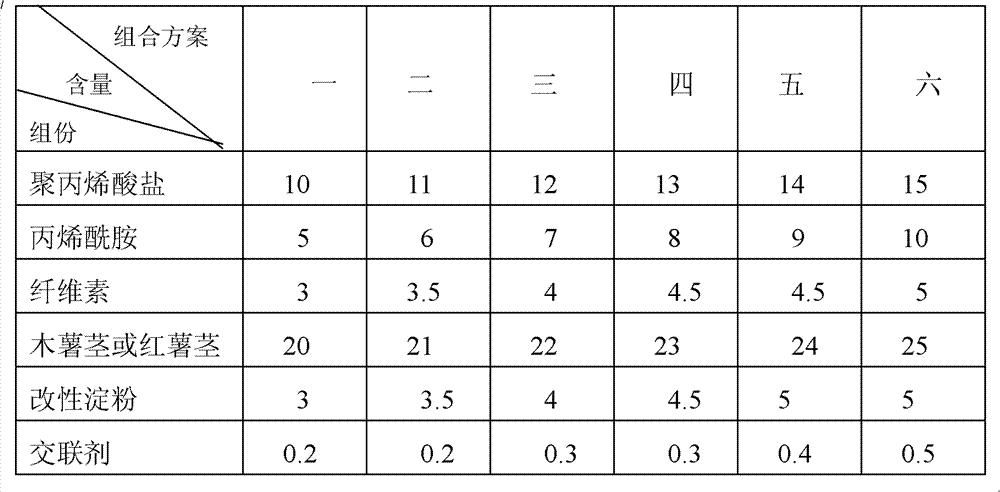

The invention discloses an automatic blowing and pressing machine for electromagnetic valves, which comprises a base (1), a turntable (2), a laminating mechanism (3), a blowing mechanism (4) and a control box (5), wherein the base (1) is provided with a graduator (6), the turntable (2) is rotatablely connected to the base (1), a rotating shaft of the graduator (6) is connected with the lower end face of the turntable (2), the axis of the rotating shaft of the graduator (6) and the axis of the turntable (2) are in a same straight line, a position on the upper end face of the turntable (2) and close to the outer edge of the upper end face is circumferentially provided with at least three electromagnetic valve clamps (7), the at least three electromagnetic valve clamps (7) are uniformly distributed along the circumferential direction of the turntable (2), the circle center of a circumference formed by the centers of the at least three electromagnetic valve clamps (7) and the circle center of the turntable (2) are concentric, the laminating mechanism (3) is fixed in a position on the base (1) and close to the outer edge of the turntable (2), the control box (5) is fixed on the base (1), the blowing mechanism (4) is fixed in a position on the base (1) and close to the turntable (2), the blowing mechanism (4) and the laminating mechanism (3) are sequentially arranged along the rotating direction of the turntable (2), and the graduator (6), the blowing mechanism (4) and the laminating mechanism (3) are all electrically connected with the control box (5). Compared with the prior art, the automatic blowing and pressing machine disclosed by the invention has the characteristics of higher production efficiency, lower wages, relatively low energy consumption, and capability of enabling the production cost of electromagnetic valves to be lower.

Owner:NINGBO AOKAI COMBUSTION GAS APPLIANCE

Automatic blowing and pressing machine for electromagnetic valves

ActiveCN102922259BReduce in quantityReduce energy consumptionMetal working apparatusMechanical engineeringElectromagnetic valve

The invention discloses an automatic blowing and pressing machine for electromagnetic valves, which comprises a base (1), a turntable (2), a laminating mechanism (3), a blowing mechanism (4) and a control box (5), wherein the base (1) is provided with a graduator (6), the turntable (2) is rotatablely connected to the base (1), a rotating shaft of the graduator (6) is connected with the lower end face of the turntable (2), the axis of the rotating shaft of the graduator (6) and the axis of the turntable (2) are in a same straight line, a position on the upper end face of the turntable (2) and close to the outer edge of the upper end face is circumferentially provided with at least three electromagnetic valve clamps (7), the at least three electromagnetic valve clamps (7) are uniformly distributed along the circumferential direction of the turntable (2), the circle center of a circumference formed by the centers of the at least three electromagnetic valve clamps (7) and the circle center of the turntable (2) are concentric, the laminating mechanism (3) is fixed in a position on the base (1) and close to the outer edge of the turntable (2), the control box (5) is fixed on the base (1), the blowing mechanism (4) is fixed in a position on the base (1) and close to the turntable (2), the blowing mechanism (4) and the laminating mechanism (3) are sequentially arranged along the rotating direction of the turntable (2), and the graduator (6), the blowing mechanism (4) and the laminating mechanism (3) are all electrically connected with the control box (5). Compared with the prior art, the automatic blowing and pressing machine disclosed by the invention has the characteristics of higher production efficiency, lower wages, relatively low energy consumption, and capability of enabling the production cost of electromagnetic valves to be lower.

Owner:NINGBO AOKAI COMBUSTION GAS APPLIANCE

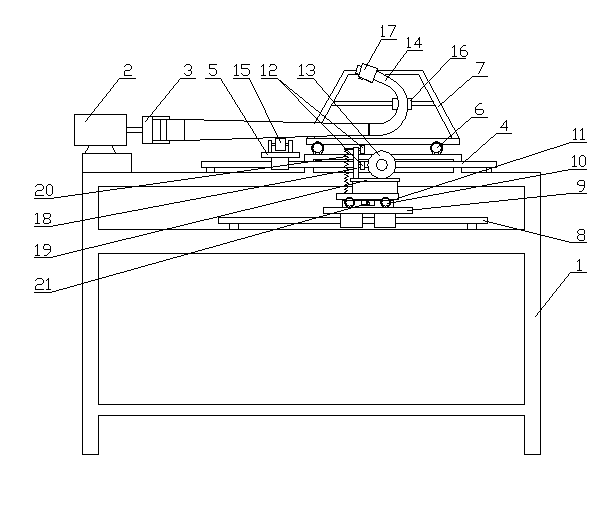

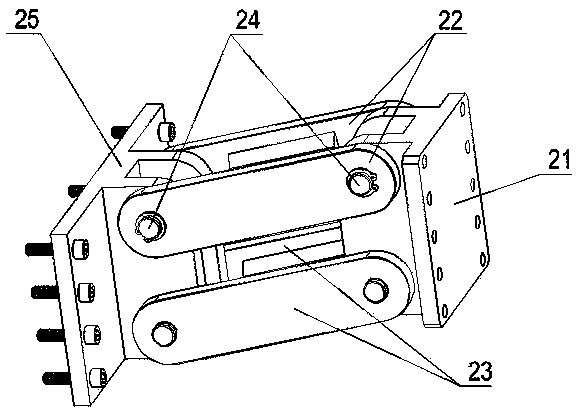

Muffler profiling welding machine

InactiveCN103722309ASolve hard to find puzzlesSave labor wagesWelding/cutting auxillary devicesAuxillary welding devicesHighly skilledEngineering

The invention discloses a muffler profiling welding machine. A supporting sliding rail is transversely fixed on a machine frame, a supporting sliding plate is movably arranged on the supporting sliding rail, a positioning rail is longitudinally fixed on the machine frame, a positioning trolley is movably arranged on the longitudinal positioning rail, a transverse profiling welding trolley is movably arranged on a transverse profiling welding rail, a longitudinal profiling welding rail is fixed on the transverse profiling welding trolley, and a longitudinal profiling welding trolley is movably arranged on the longitudinal profiling welding rail. The muffler profiling welding machine has the advantages of not only greatly improving working efficiency but also effectively guaranteeing welding quality, achieving consistency of the welding quality, saving high labor wages of highly-skilled technicians, effectively solving the problem that the highly-skilled technicians are difficult to find, and being very easy and convenient to operate.

Owner:钟祥市荆楚兴消声器厂

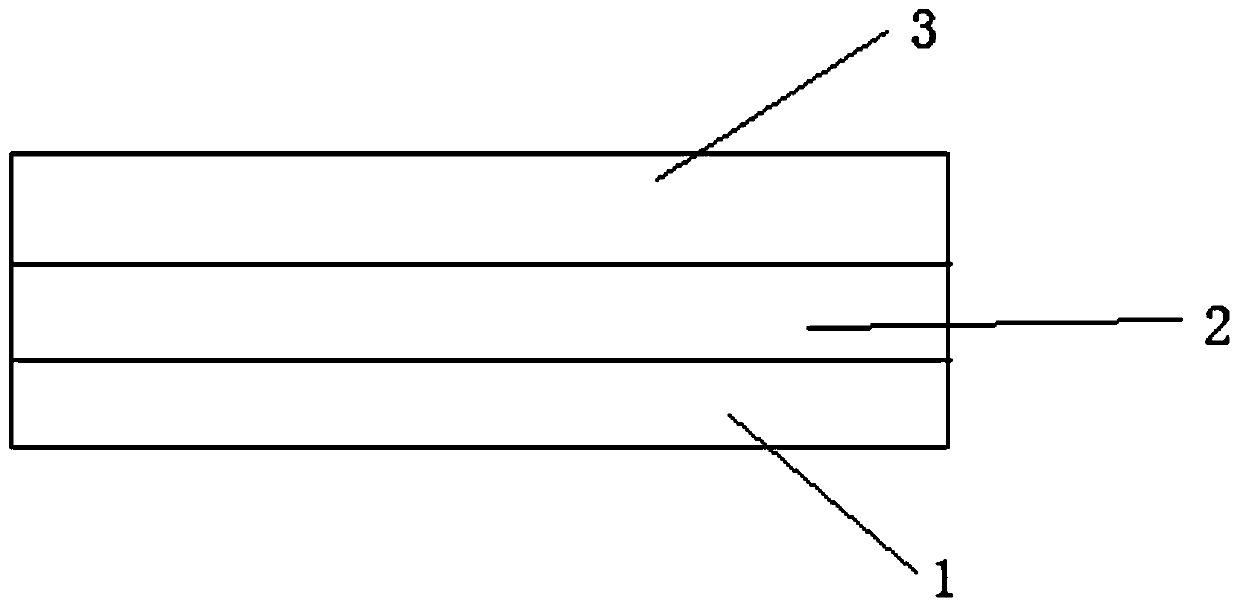

Waterproof and corrosion-resistant flowerpot side plate

InactiveCN109937739ARealize industrial mass productionStrong enoughReceptacle cultivationEngineeringUltimate tensile strength

The invention discloses a waterproof and corrosion-resistant flowerpot side plate, which comprises a left joint part, a plate body, a right joint part and bottom plate connection holes. The left jointpart and the right joint part are arranged at left and right ends of the plate body respectively, lower end faces of the left joint part and the right joint part are flush with the lower end face ofthe plate body, and the lower section of the plate body is provided with the bottom plate connection holes. Since the flowerpot side plate is designed in a barrel assembly structure with split side plates in joint connection, the split side plates are pressed parts, high strength and corrosion resistance are achieved, and industrial mass production is realized; the parts are classified for packaging and transporting and assembled on site, production efficiency is improved by 20 times as compared with that of manual production, and transporting cost is reduced by 50%-70%.

Owner:赵娜娜

Edible mushroom inoculation method

InactiveCN110226460APrevent the invasion of bacteriaReduced chance of landingCultivating equipmentsMushroom cultivationEdible mushroomInoculation methods

The invention relates to an edible mushroom inoculation method. The method comprises following steps: (1), an edible mushroom stick is sterilized; (2), bamboo is cut to form bamboo nails which are 10mm thick and 50 mm long, the bamboo nails are inoculated with edible mushroom strains, and bamboo nails with production stains are obtained by fermentation; 3), the two ends of the edible mushroom stick are not required to be uncovered, the bamboo nails with production stains are directly inserted into the center of the edible mushroom stick, and edible mushroom inoculation is completed. Comparedwith the prior art, high-yield and high-quality edible mushroom products can be obtained under the same cultivation condition, and large-scale popularization and application are facilitated.

Owner:王问渠

Coupling compound moulded coal binder and preparation method thereof

InactiveCN101798538BWater evaporates quicklyIncrease production capacitySolid fuelsCross-linkCellulose

The invention discloses a coupling compound moulded coal binder and a preparation method thereof. The coupling compound moulded coal binder is a mixture prepared by mixing bentonite, tackifier, sodium carbonate, kaolin and sodium humate; the mixture comprises the following components in parts by weight: 350-600 parts of the bentonite, 45-55 parts of the tackifier, 3-5 parts of the sodium carbonate, 280-320 parts of the kaolin and 100-125 parts of the sodium humate; the tackifier is prepared by smashing 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stalk, 3-5 parts by weight of modified starch and 0.2-0.5 part by weight of cross-linking agent into 50-100 meshes, and mxing the smashed materials. The preparation method comprises the following steps: preparing the tackifier, stocking, pretreating parts of the components, mixing, stirring and the like. The moulded coal binder has favorable waterabsorbtion performance, the moisture of an extruded and shaped coal bar is quickly evaporated and is easy to dry, thus solving the problems of high raw coal moisture, difficult moulded coal production and low shaping rate in rainy days in the south of China.

Owner:柳州化工股份有限公司 +2

Hammer minced meat machine

The invention discloses a hammering-type meat emulsion maker. The hammering-type meat emulsion maker solves the technical problems that processing of food material beef emulsion in a background technique needs to be completed in the manner of performing manual and continuous hammering with an iron bar or a solid wood bar, so that the efficiency is low; and besides, an air hammer is used for replacing manual operation, so that the defects of being large in size and large in noise exist. The invention adopts the technical scheme that the hammering-type meat emulsion maker comprises a support frame, wherein a rotating working table is vertically arranged on the support frame, and cantilevers are arranged on the support frame; a crank connecting link mechanism which is matched with the rotating working table for operation and is used for hammering meat is arranged on the cantilevers; and a power part for driving the crank connecting link mechanism to move is arranged at the top of the crank connecting link mechanism. The hammering-type meat emulsion maker disclosed by the invention has the beneficial effect that the machine size is small, the size of the hammering-type meat emulsion maker is smaller than that of the air hammer, besides, noise generated by exhaust of the air hammer does not exist, and the noise is low.

Owner:青海五三六九生态牧业科技有限公司

Muffler profiling welding machine

InactiveCN103722309BSolve hard to find puzzlesSave labor wagesWelding/cutting auxillary devicesAuxillary welding devicesHighly skilledEngineering

The invention discloses a muffler profiling welding machine. A supporting sliding rail is transversely fixed on a machine frame, a supporting sliding plate is movably arranged on the supporting sliding rail, a positioning rail is longitudinally fixed on the machine frame, a positioning trolley is movably arranged on the longitudinal positioning rail, a transverse profiling welding trolley is movably arranged on a transverse profiling welding rail, a longitudinal profiling welding rail is fixed on the transverse profiling welding trolley, and a longitudinal profiling welding trolley is movably arranged on the longitudinal profiling welding rail. The muffler profiling welding machine has the advantages of not only greatly improving working efficiency but also effectively guaranteeing welding quality, achieving consistency of the welding quality, saving high labor wages of highly-skilled technicians, effectively solving the problem that the highly-skilled technicians are difficult to find, and being very easy and convenient to operate.

Owner:钟祥市荆楚兴消声器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com