Waterproof and corrosion-resistant flowerpot side plate

A technology of side panels and flower pots, applied in the field of split and combined flower pots, can solve the problems of high manual production cost, irreparable, scrapped and replaced, and achieve the goals of improving workers' occupational health, changing product structure, and saving replacement costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

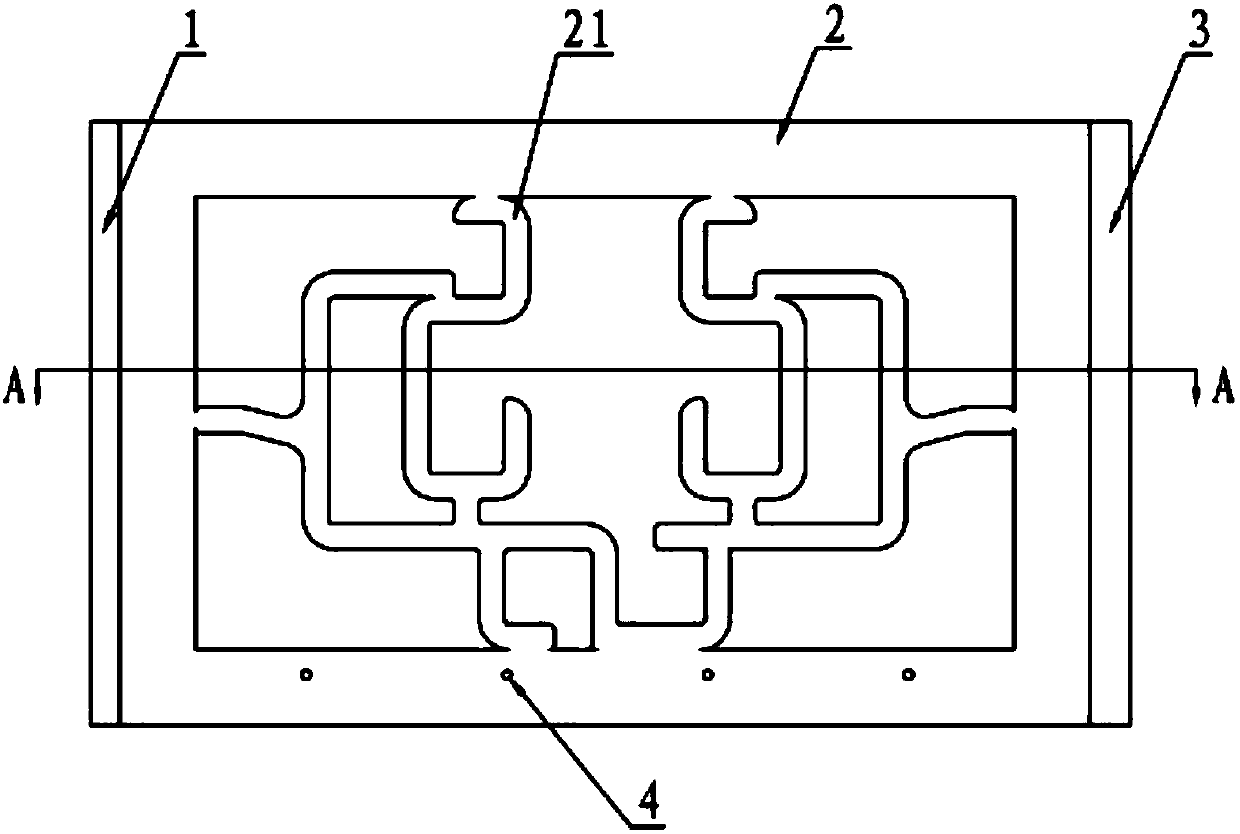

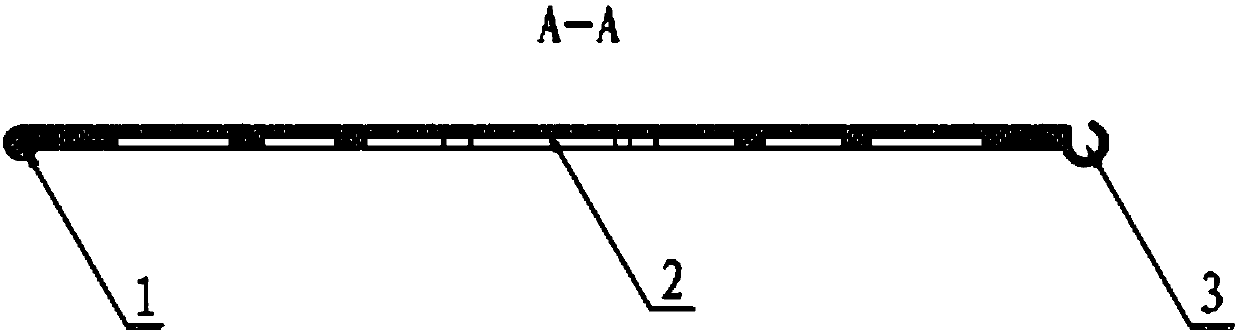

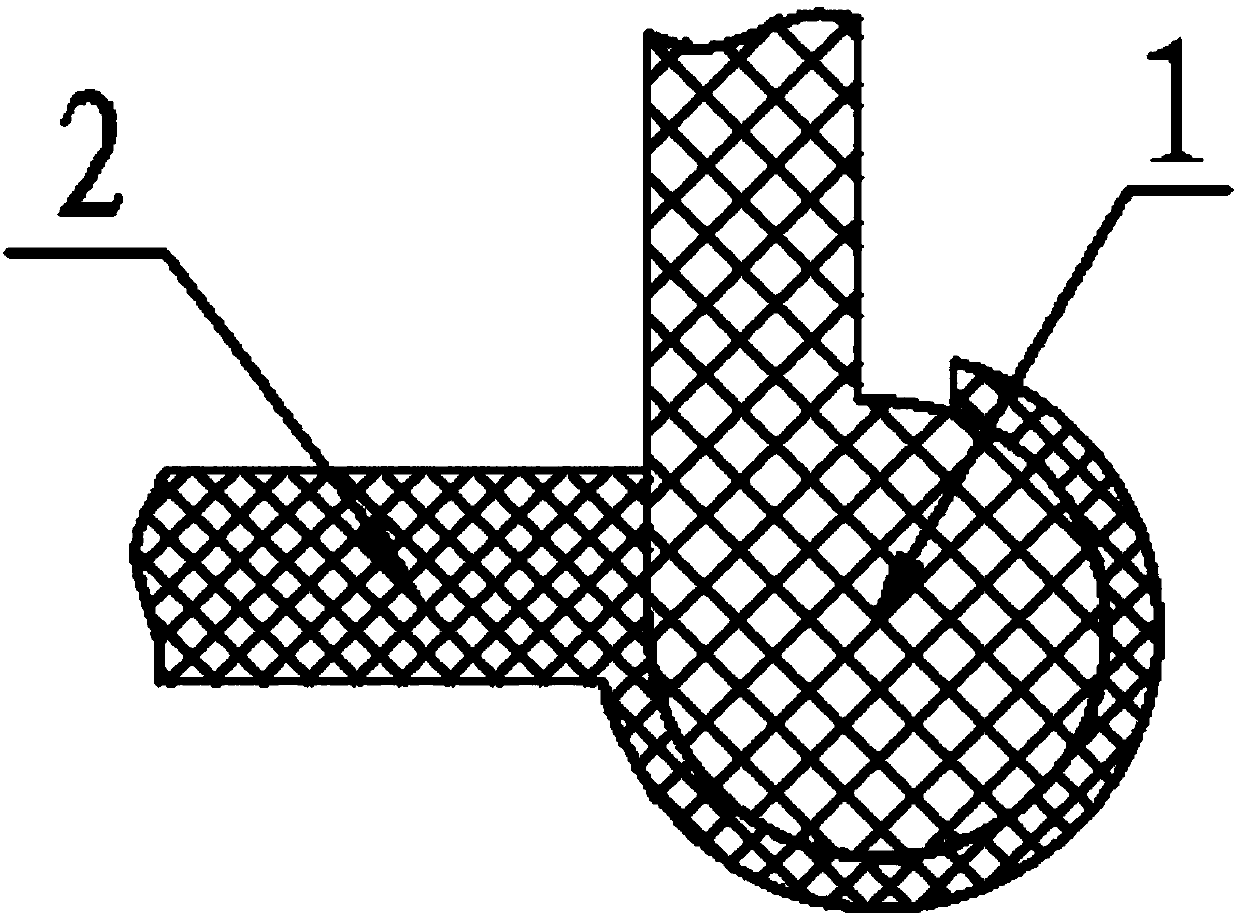

[0023] Embodiment 1: A waterproof and anti-corrosion flowerpot side plate, which is composed of a left connecting piece 1, a plate body 2 and a right connecting piece 3, the left connecting piece 1 is a connecting convex body, and the right connecting piece 3 is a connecting notch, and the connecting piece The convex body and the connecting notch are respectively arranged at the left and right ends of the plate body 2, the cross-sectional shape of the connecting convex body is a handle circular shape, the cross-sectional shape of the connecting notch is an open circular shape, and the connecting convex body is inserted into the connecting notch , there is a gap fit between the two, and four chassis connection holes 4 are arranged on the lower part of the board body 2. The material of the side board is plastic-wood composite material. In order to improve the strength of the side board, reduce the material used for the side board and strengthen the side board For aesthetic feelin...

Embodiment 2

[0024] Embodiment 2: The difference from Embodiment 1 lies in the structure of the left connecting piece 1 and the right connecting piece 3. The right connecting piece 3 is the same as the left connecting piece 1 and is a connecting plate, and a connecting hole is provided on the connecting plate. respectively arranged at the left and right ends of the plate body 2, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com