Muffler profiling welding machine

A technology of profiling welding and muffler, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as affecting production efficiency, improving production efficiency, slow welding speed, etc. Work efficiency, easy operation and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

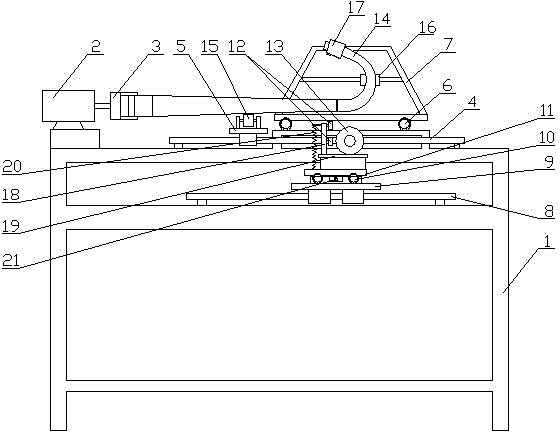

[0009] As shown in Figure 1, the muffler profiling welding machine mainly includes a frame 1, a rotary drive motor 2, claws 3, a supporting slide rail 4, a supporting slide plate 5, a positioning track 6, a positioning trolley 7, and a horizontal profiling welding machine. Track 8, profiling welding horizontal trolley 9, profiling welding longitudinal rail 10, profiling welding longitudinal trolley 11, profiling wheel 12 and welding torch 13, said rotary drive motor 2 is fixedly installed on frame 1, claw 3 is fixed On the rotating shaft of the rotary drive motor 2, when in use, the rotary drive motor 2 drives the muffler 14 to rotate through the claws 3 to realize profiling welding while rotating. Located on the same platform as the rotary drive motor 2, the support slide 5 is movably installed on the support slide 4, and the support roller 15 is movably installed on the support slide 5 to facilitate the support of the rotating muffler 14 to reduce the The rotation resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com