The method of automatically finding the starting point of welding seam based on statistics

A starting point and statistical technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of difficulty in automatically finding the starting point of the weld, and achieve the effect of flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

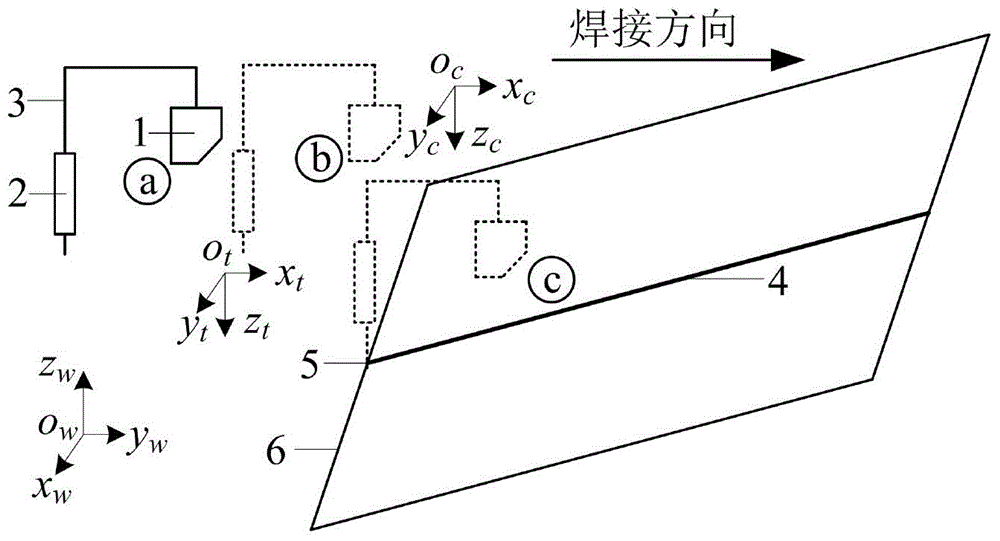

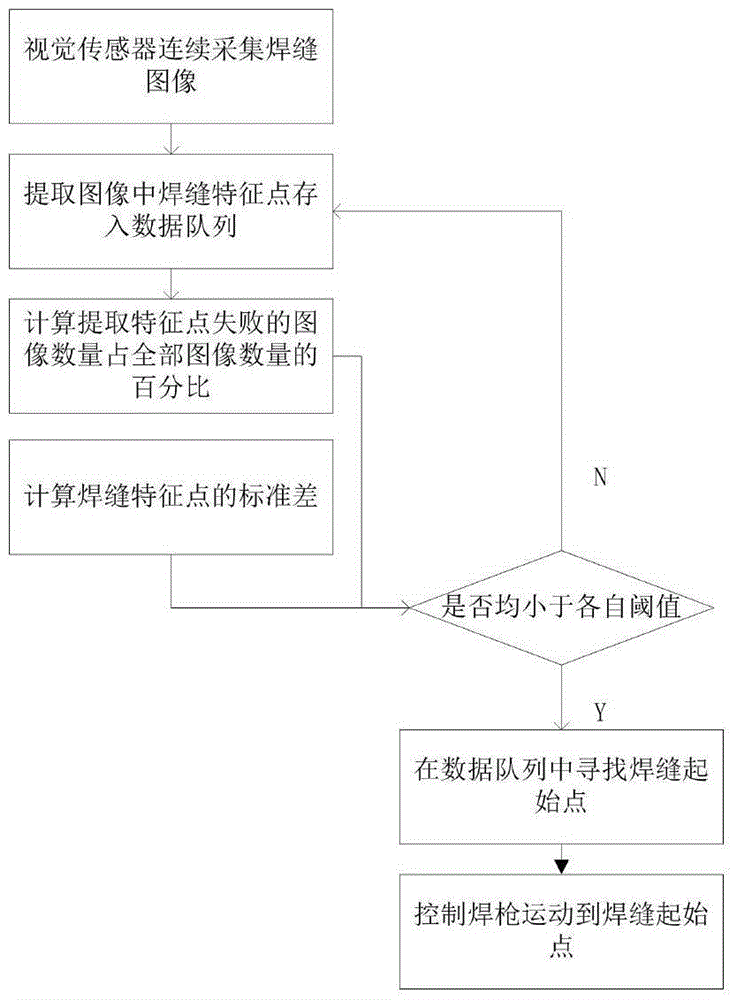

[0024] Design suitable fixtures according to the characteristics of the weldment. On the one hand, ensure that the weld 4 of the weldment is basically consistent with the welding direction. On the other hand, ensure that the fluctuation of the weld starting point 5 is within a certain range. Generally, the weld starting point 5 should be guaranteed The fluctuation range of the XYZ three coordinates is limited within ±20mm. The fluctuation range of the starting point should be limited to ensure that the visual sensor must be located outside the end line of the weld every time the starting point is searched. Avoid excessive fluctuations in the starting point, causing the visual sensor to go to the inside of the weld, and the algorithm will go wrong.

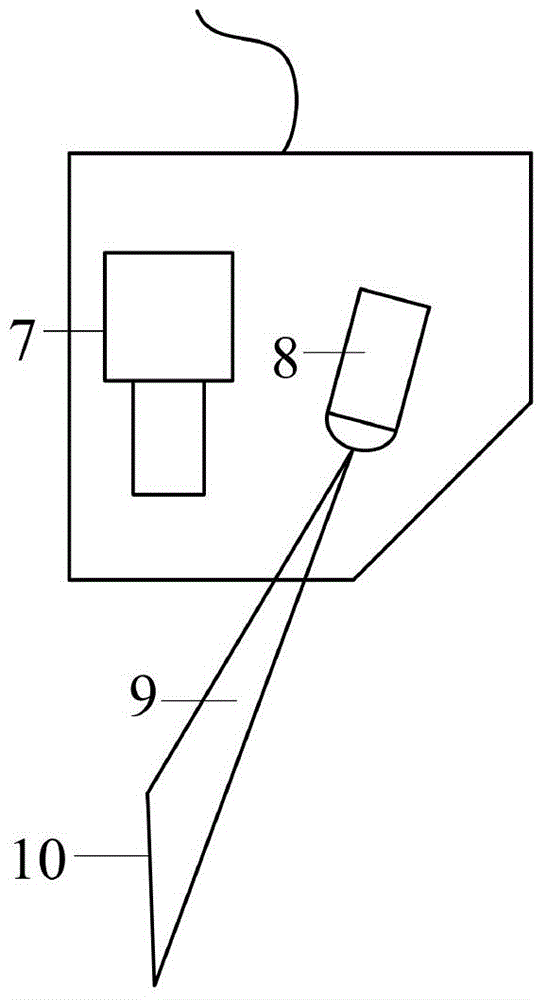

[0025] Such as figure 1 and figure 2 As shown, the welding torch 2 and the visual sensor 1 are installed on the actuator, and the actuator drives the welding torch 2 and the visual sensor 1 to move horizontally or vertically dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com