A template-free preparation method of hierarchical porous activated carbon electrode material

A technology of hierarchically porous and activated carbon, which is applied to the template-free preparation of porous activated carbon materials and the preparation of electrode materials. looking for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, 2 mg of commercial microporous activated carbon and 4 mg of potassium hydroxide were weighed, mixed and ground in a mortar, then calcined at a high temperature (at a temperature of 600 °C), and the calcined product was washed with dilute hydrochloric acid and deionized water. Until the pH value of the solution was 7, it was centrifuged again, and the resulting precipitate was dried at 70°C for 12 hours to obtain the first activated product, and then 1 mg of the first activated product and 3 mg Potassium hydroxide is fully mixed and ground in a mortar, and calcined at a high temperature (temperature is 600°C), and the product calcined at high temperature is washed with dilute hydrochloric acid and deionized water until the pH value of the solution is 7, and then centrifuged After treatment, the obtained precipitate was dried at 70° C. for 12 hours to obtain a hierarchical porous activated carbon electrode material.

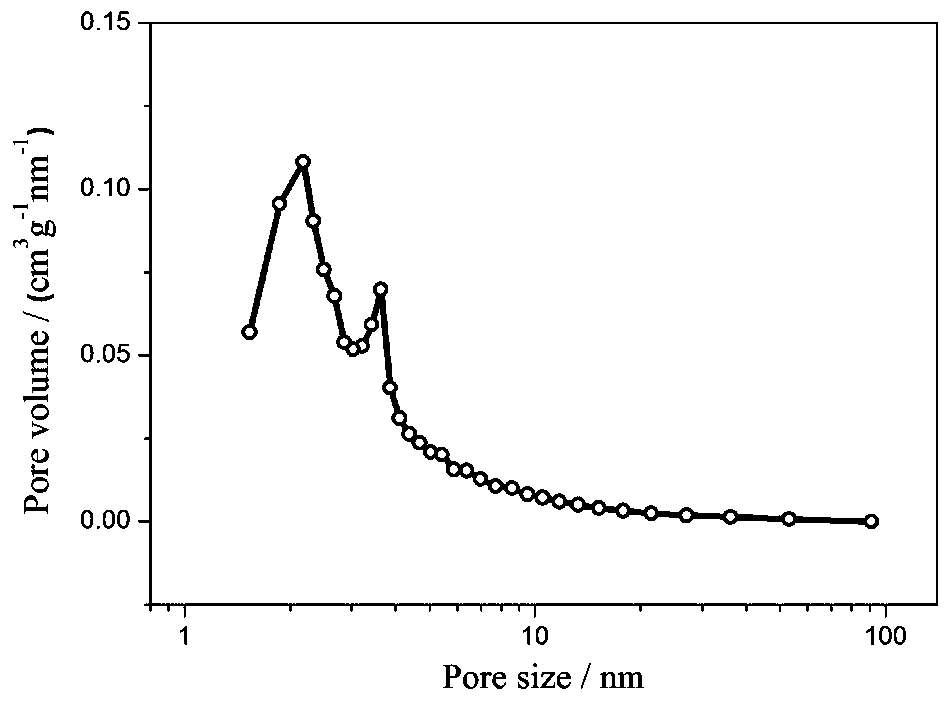

[0025] The pore size distribution of the prepar...

Embodiment 2

[0027] First, 2 mg of commercial microporous activated carbon and 8 mg of potassium hydroxide were weighed, mixed and ground in a mortar, then calcined at a high temperature (at a temperature of 700 °C), and the calcined product was washed with dilute hydrochloric acid and deionized water. Until the pH value of the solution was 7, it was centrifuged again, and the resulting precipitate was dried at 50°C for 12 hours to obtain the first activated product, and then 1 mg of the first activated product and 4 mg Potassium hydroxide is fully mixed and ground in a mortar and then calcined at high temperature (temperature is 500°C). The product calcined at high temperature is washed with dilute hydrochloric acid and deionized water until the pH value of the solution is 7, and then it is centrifuged. , and the resulting precipitate was dried at 50°C for 8 hours to obtain a hierarchical porous activated carbon electrode material.

Embodiment 3

[0029] First, 2 mg of commercial microporous activated carbon and 6 mg of potassium hydroxide were weighed, mixed and ground in a mortar, and then calcined at a high temperature (at a temperature of 800 °C). The calcined product was washed with dilute hydrochloric acid and deionized water. Until the pH value of the solution was 7, it was then centrifuged, and the resulting precipitate was dried at 60°C for 8 hours to obtain the first activated product, and then 1 mg of the first activated product and 1 mg Potassium hydroxide is thoroughly mixed and ground in a mortar and then calcined at high temperature (at a temperature of 700°C). The product calcined at high temperature is washed with dilute hydrochloric acid and deionized water until the pH value of the solution is 7, and then centrifuged. , and the resulting precipitate was dried at 50° C. for 12 hours to obtain a hierarchical porous activated carbon electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com