Centrifugal pump group routing inspection intelligent robot and operation method thereof

A technology of intelligent robots and operating methods, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of intelligent robots and operating methods for inspection of centrifugal pump groups that have not been seen, and achieve human resource cost savings, balanced production and safety Production and the effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

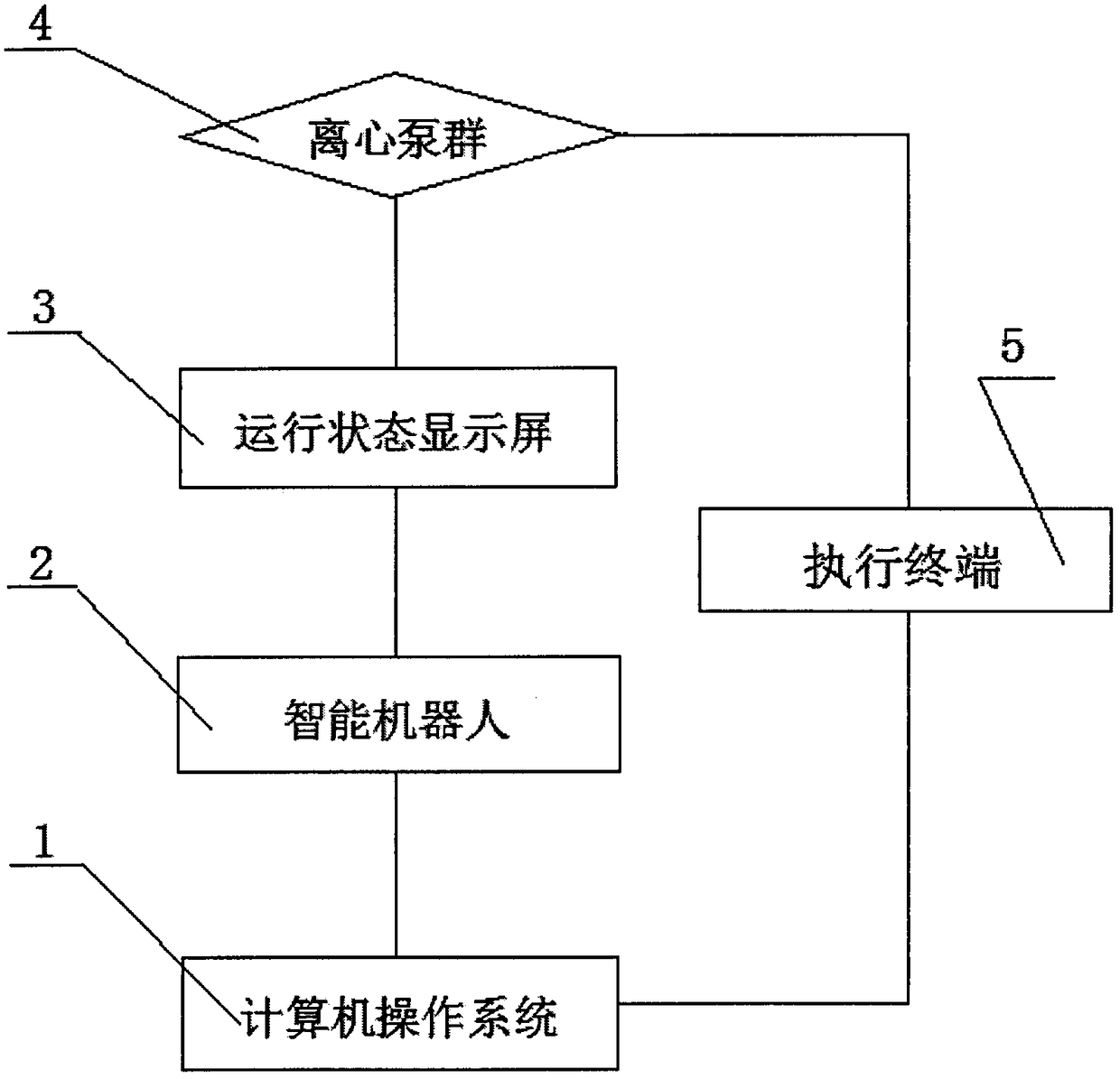

[0022] Such as figure 1 As shown, a centrifugal pump group inspection intelligent robot and its operation method are composed of a computer operating system 1, an intelligent robot 2, a running status display screen 3, a centrifugal pump group 4, and an execution terminal 5, and is characterized in that: the intelligent robot 2 performs inspection The object is the process and water supply centrifugal pump group 4 of the process industry factory; each centrifugal pump uses a corresponding sensor to centrally display various operating state parameters of the centrifugal pump in the form of codes on the operating state display screen 3, and the operation of the centrifugal pump The operating status parameters displayed on the status display screen 3 include: pump outlet pressure, pump operating power, bearing temperature, lubricating oil water content, shaft seal leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com