Coupling compound moulded coal binder and preparation method thereof

A composite briquette and binder technology, which is applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of low water absorption rate of binder, energy consumption, and difficulty in production and use, so as to reduce drying time and improve production Ability, fast water evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A coupling composite briquette binder is a mixture composed of bentonite, tackifier, soda ash, kaolin and sodium humate. The content of each component in the mixture is calculated in parts by weight:

[0040] 550 parts by weight of bentonite, 50 parts by weight of tackifier, 3 parts by weight of soda ash,

[0041] Kaolin: 320 parts by weight, 125 parts by weight of sodium humate.

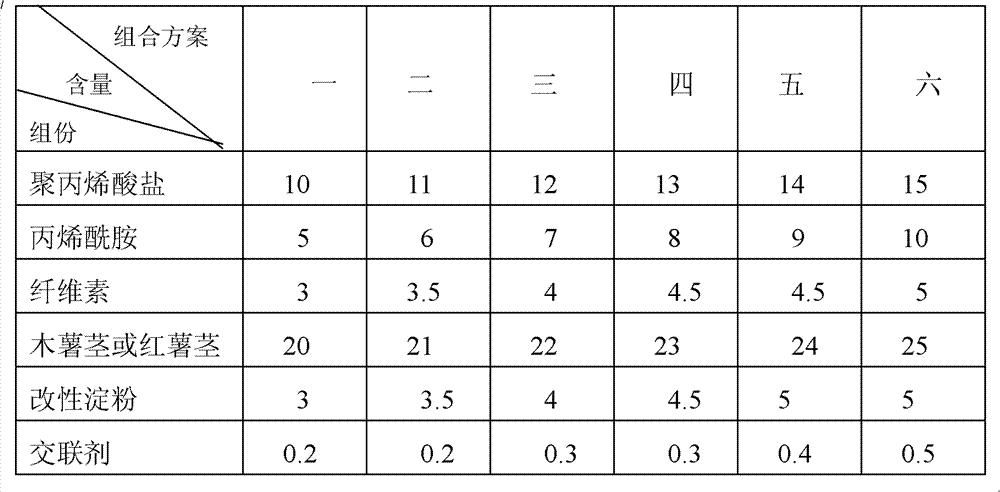

[0042] The thickening agent is composed of 12 parts by weight of polyacrylate, 7 parts by weight of acrylamide, 4 parts by weight of cellulose, 22 parts by weight of cassava stems, 4 parts by weight of modified starch, and 0.3 parts by weight of crosslinking agent. The 80-mesh powder is uniformly mixed.

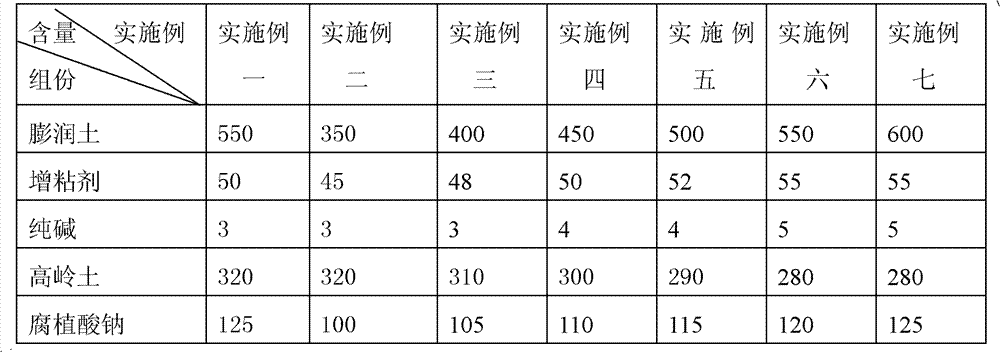

Embodiment 2 Embodiment 7

[0044] A kind of coupled composite briquette binder is a mixture composed of bentonite, tackifier, soda ash, kaolin and sodium humate. The content of each component in the mixture is calculated in parts by weight (see attached table 1 ):

[0045] 350-600 parts of bentonite, 45-55 parts of tackifier, 3-5 parts of soda ash,

[0046]Kaolin: 280-320 parts, sodium humate 100-125 parts;

[0047] For the component content mixture described in each embodiment, the sodium humate includes sodium humate and sodium humate;

[0048] The thickening agent is composed of 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stem or sweet potato stem, 3-5 parts by weight of modified starch Parts by weight and 0.2-0.5 parts by weight of cross-linking agent are crushed into 50-100 meshes and then mixed. 6 types, each embodiment can choose one or more of them.

[0049] In the component of the tackifier des...

Embodiment 8

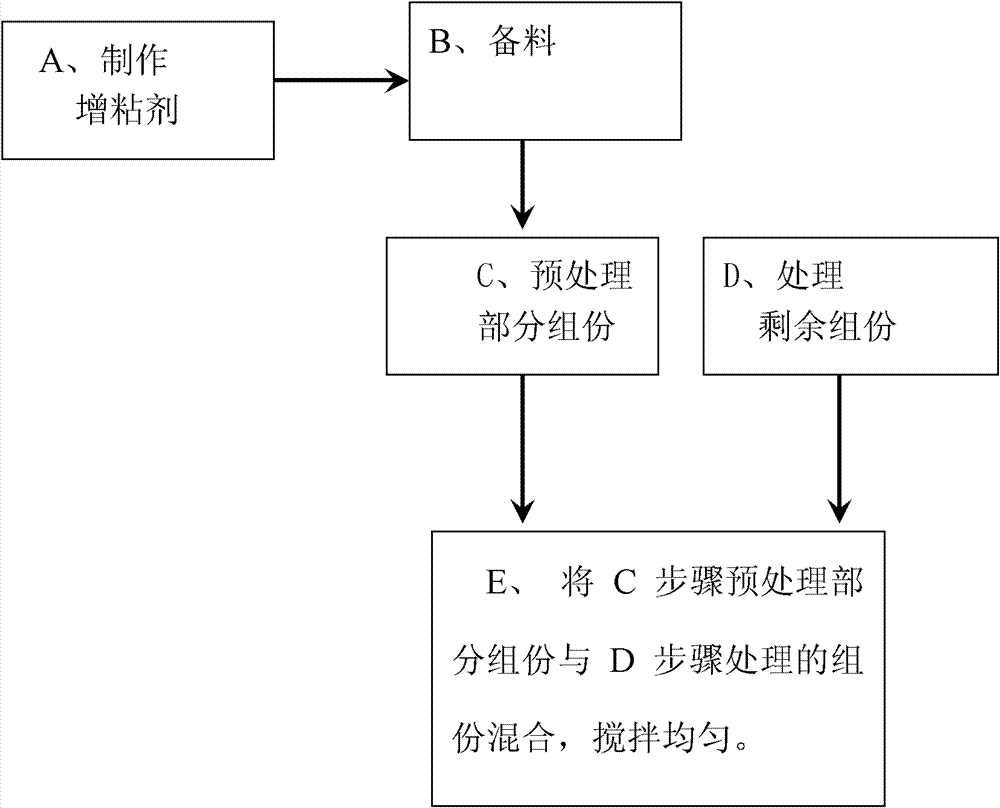

[0058] A kind of preparation method of coupling composite briquette binder, it comprises the following steps:

[0059] A. Making tackifier: Take the components of the tackifier according to the following proportions and grind them into 50-100 meshes before mixing:

[0060] 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava radial leaves, 3-5 parts by weight of modified starch, 0.2-0.5 parts by weight of cross-linking agent share;

[0061] B, getting the raw materials ready: take by weighing each component thing of making coupling compound briquette binder according to the following ratio, and the ratio of each component is calculated as in parts by weight:

[0062] 350-600 parts by weight of bentonite, 45-55 parts by weight of tackifier, 3-5 parts by weight of soda ash,

[0063] Kaolin: 280-320 parts by weight, 100-125 parts by weight of sodium humate;

[0064] C. Part of the pretreat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com