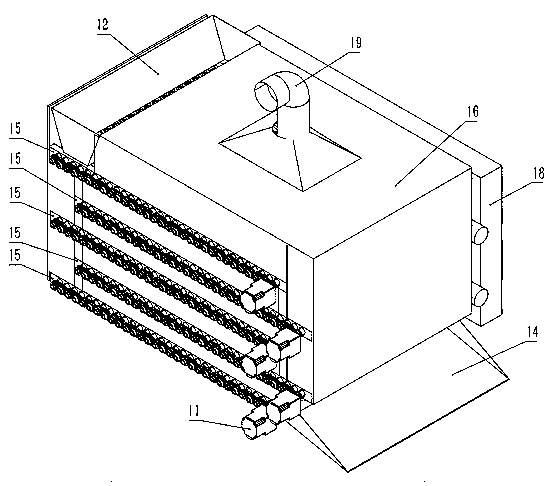

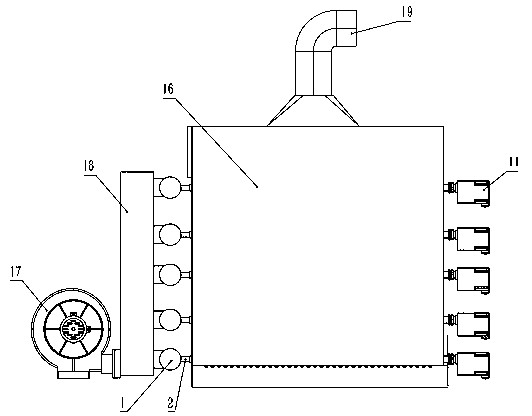

Roller piece crossing combined conveying type supporting pipe exhaust dryer

A technology of cross-combination and support tubes, which is applied in the direction of progressive dryers, dryers, and drying solid materials, etc., which can solve the problems of uneven heating of drying materials, waste of space resources, and poor penetration of hot air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

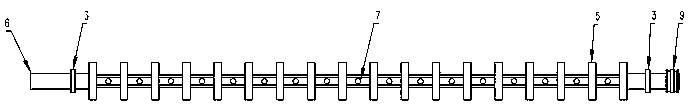

[0020] Such as Figure 4 As shown, the figure is a top view of the roller plate cross combined conveying mechanism 15. It can be seen from the figure that the conveying mechanism consists of a plurality of roller support tubes 6 placed longitudinally and horizontally laid, and bearings 3 are respectively installed at both ends of the roller support tubes 6. , the bearing 3 is fixed on the bearing supports 4 at both ends, and the double-groove transmission wheel 9 is installed at one end of the roller support tube 6, and each double-slot transmission wheel 9 is connected with the adjacent double-slot transmission wheel with a transmission belt 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com