Three-axis sectioning multi-blade saw

A multi-blade saw and saw shaft technology, which is applied in the direction of circular saws, sawing equipment, manufacturing tools, etc., can solve the problems of high labor wages, high cost of finished products, and high equipment costs, so as to reduce labor wages, reduce purchase costs, and account for The effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

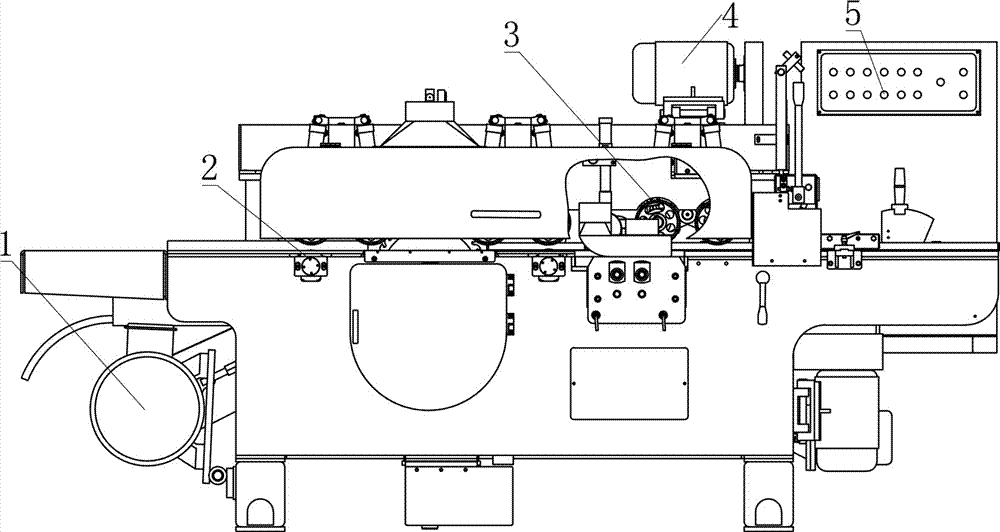

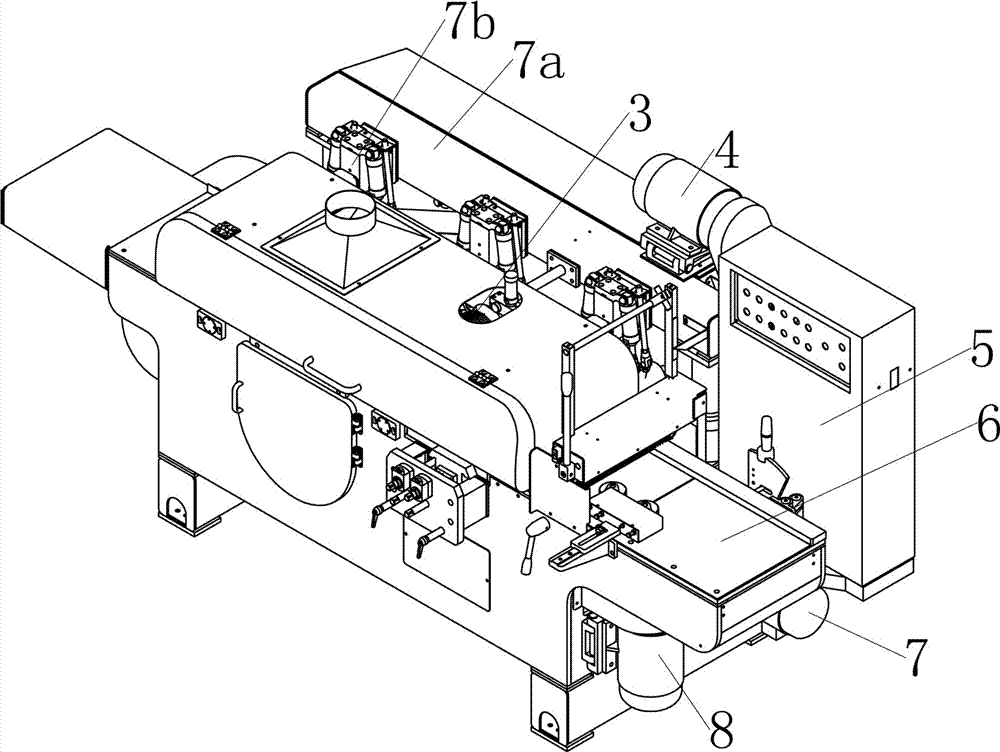

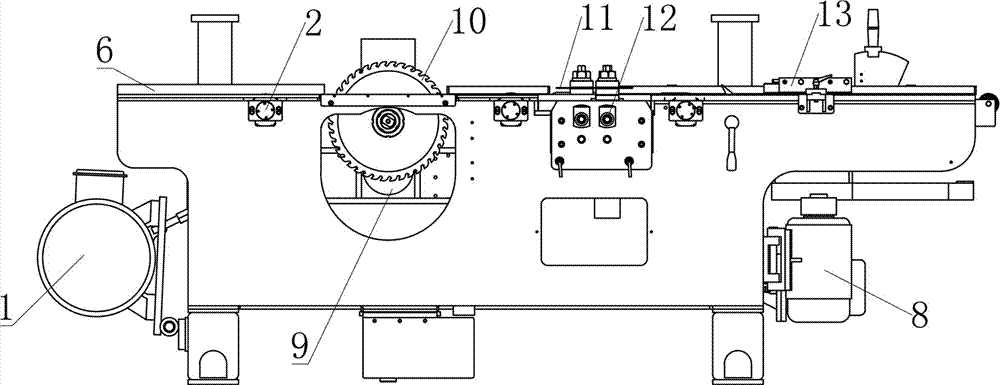

[0024] A three-axis cutting multi-blade saw, including a fuselage that carries other components and loads wood. The fuselage is provided with a workbench 6, a console 5, a main motor 1, a saw shaft installation and a saw shaft installation lifting motor 14, Saw shaft portion adorns lifting motor 14 and is conducive to the replacement and maintenance of saw blade. The saw shaft part includes a saw shaft motor 9 and a horizontal shaft multi-blade saw 10. Several circular feeding wheels 2 are arranged on the workbench, and several toothed feeding wheels 3 are arranged directly above the circular feeding wheel 2. Equipped with a pressing cylinder 7b and installed on the liftable beam 7a, the beam lifting motor 7 controls the lifting height of the beam, that is, the pressing height of the toothed feed wheel 3 can be appropriately adjusted according to the thickness of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com