Method for continuously manufacturing electric welding rod and short welding rod of nanometer coating compatibly

A nano-coating, welding rod technology, applied in manufacturing tools, welding media, welding equipment, etc., can solve the problems of poor product quality, poor copper plating process in small-diameter welding wire manufacturers, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

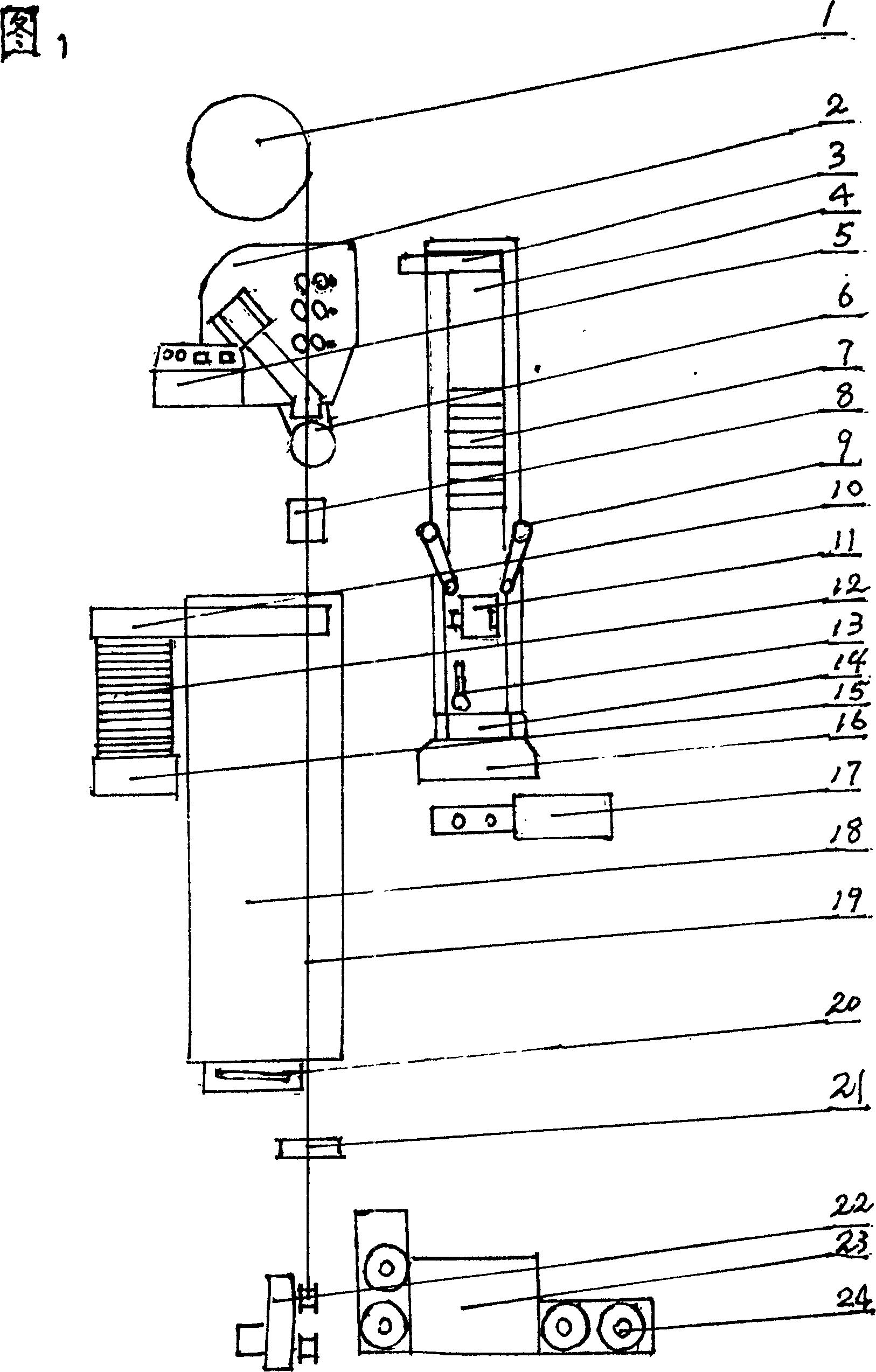

[0009] Now according to accompanying drawing 1 description specific embodiment, take the nanometer short welding rod of compatible manufacture 4mm nano-coating continuous welding rod and the same diameter as example, the present invention is further described:

[0010] The continuous welding rod steel core on the nanometer continuous welding rod welding core disk circle placement frame 1 is coated with nano-coating by the stepless speed-adjusting automatic strip powder coating unit 2, and then sprayed with a colored nano-protective film by the nano-protective film sprayer 6, and introduced The three-layer transmission automatic oven 18 dries the outer layer of the drug skin, and is wound into a quantitative disc by the double-drum winder 22 . Continuous electric welding rod is cut off with disc type steel bar cutter 21, and broken end is introduced into double-drum winder 22 to continue production; When manufacturing armored type continuous electric welding rod, then close the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com