Efficient wet type dust collection and desulfuration integrated tower

A wet-type dedusting and high-efficiency technology, applied in chemical instruments and methods, using liquid separating agents, and separating dispersed particles, etc., can solve problems such as poor dehydration effect, serious secondary pollution, and serious water carried by fans, so as to save manpower and Labor wages, no secondary pollution, good environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

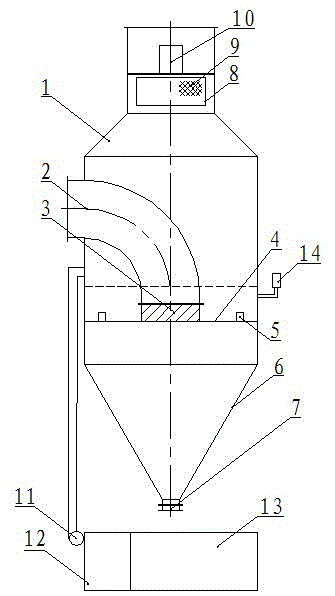

[0017] A high-efficiency wet dust removal and desulfurization integrated tower, including a cylinder body 1, an air inlet pipe 2, a turbine 3, a differential plate 4, an ultrasonic vibrator 5, an ash bucket 6, an automatic ash valve 7, a packing cylinder 8, a packing 9, High-temperature and high-humidity motor 10, water pump 11, alkaline water pool 12, drying pool 13; high-temperature and high-humidity motor 10 is arranged on the top of the cylinder body 1, and a packing tube 8 is arranged under the high-temperature and high-humidity motor 10, and inside the packing tube 8 is a There is a filler 9, and the dust-laden water droplets carried in the flue gas are thrown to the cylinder wall and flow into the water in the lower part of the cylinder body 1 under the action of centrifugal force; the cylinder body 1 is provided with a differential plate 4, and the diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com