A roadbed slope protection truss trolley and its construction method

A technology for slope protection and truss, which is used in infrastructure engineering, excavation, construction, etc., can solve the problems of poor flatness of concrete pouring, difficulty in reverse transportation, installation and fixation, and low work efficiency, so as to facilitate installation and disassembly and save labor. Low wages, environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

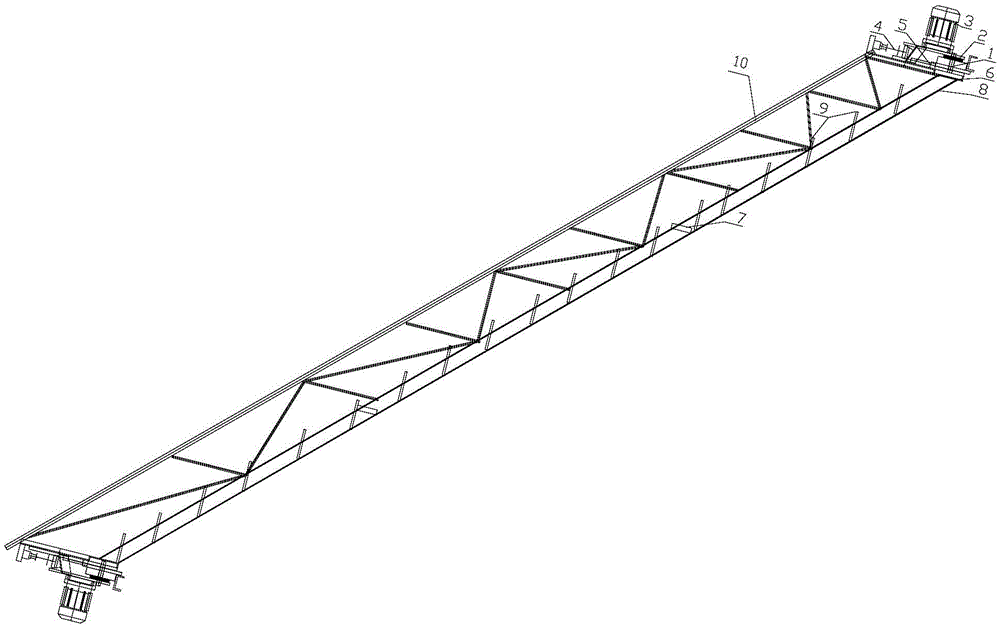

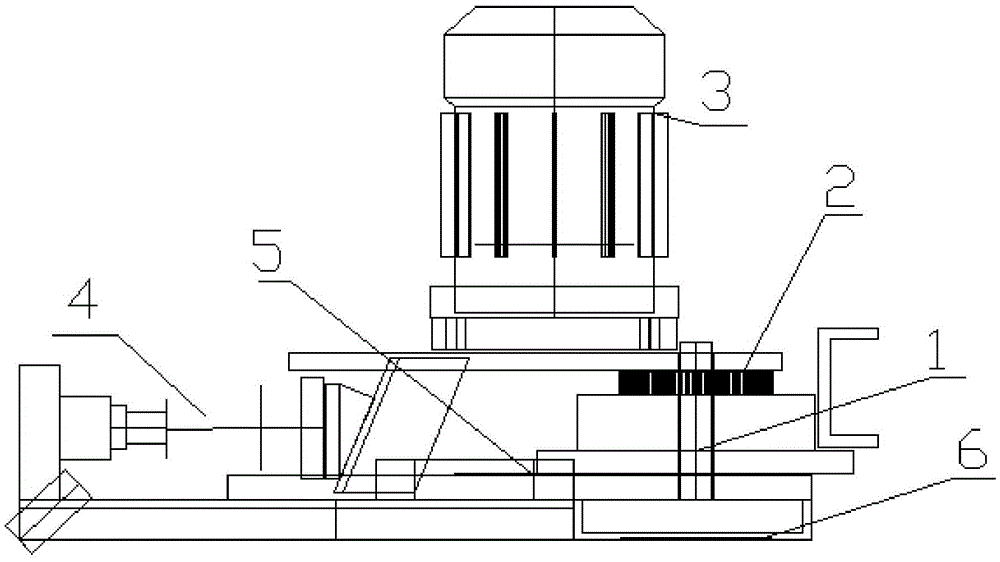

[0030] A roadbed slope protection truss trolley, comprising a truss 10, a trolley automatic running system, an elevation adjustment system and a formwork fixing system, the trolley automatic running system includes a roller 1, a gear 2 and a motor 3, and the motor 3 is connected through a rotary bearing Gear 2, gear 2 and roller 1 are closely welded together, roller 1 moves along the track, and the rotary bearing adopts high-alloy steel standard bearings, which are common high-performance bearings in the market, easy to purchase or manufacture, and also save new product development costs , which is convenient for product promotion, realizes the automatic running of the trolley on the track, and effectively improves the construction speed. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com