Hot melt adhesive for shoe material, preparation method, shoe material applying hot melt adhesive and shoe material manufacturing method

A production method and technology of hot melt adhesive, applied in the application, footwear, adhesive and other directions, can solve the problems of easy falling off, complicated process, not strong enough adhesive force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

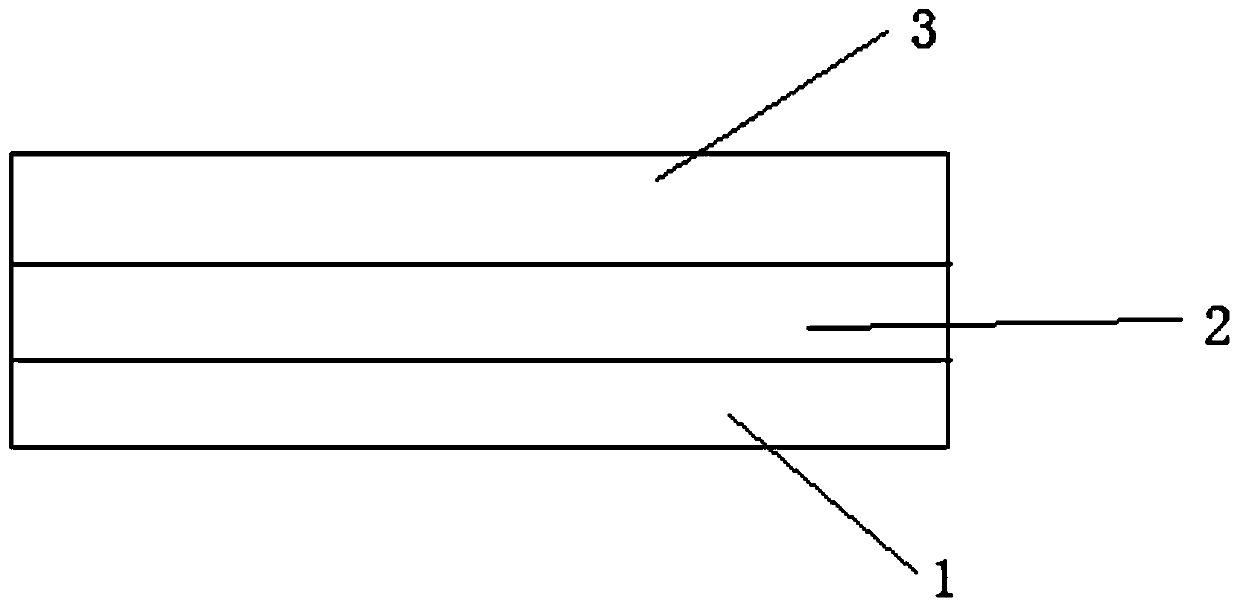

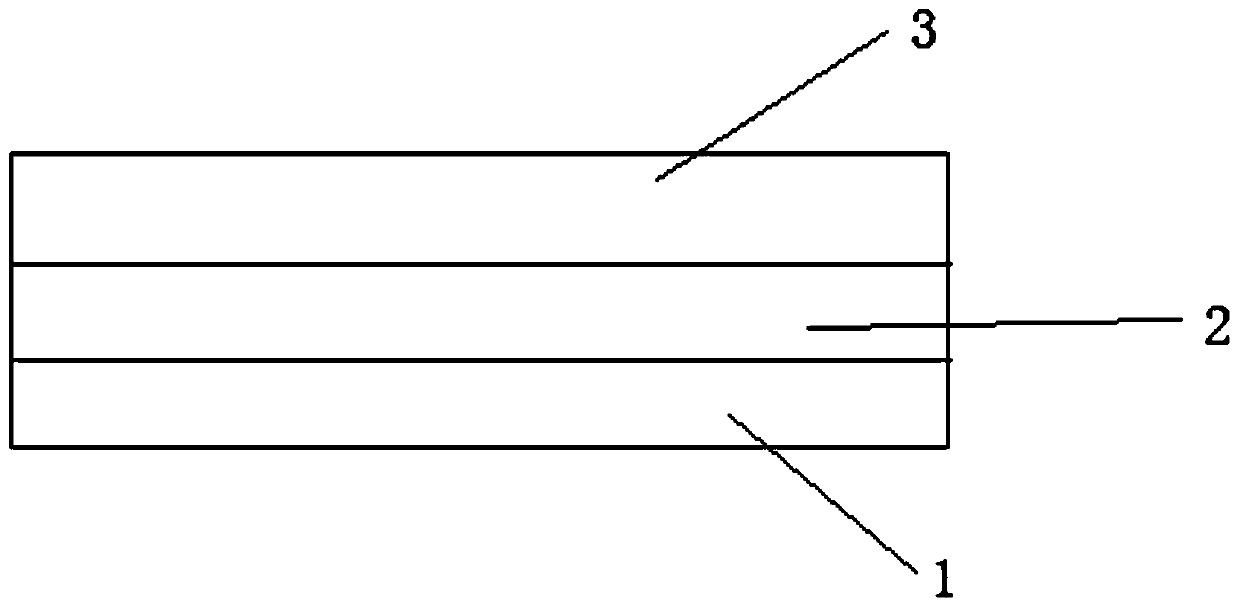

Image

Examples

Embodiment 1

[0034] Embodiment one, a kind of preparation method of hot-melt adhesive for shoe material, comprises the following steps:

[0035] 1) Weigh raw materials, thermoplastic polyurethane elastomer 85kg, ethylene-ethyl acetate copolymer 15kg;

[0036] 2) Stir at room temperature;

[0037] 3) Heat the stirred mixture to 165 degrees.

Embodiment 2

[0038] Embodiment two, a kind of preparation method of hot-melt adhesive for shoe material, comprises the following steps:

[0039] 1) Weigh raw materials, thermoplastic polyurethane elastomer 80kg, ethylene-ethyl acetate copolymer 20kg;

[0040] 2) Stir at room temperature;

[0041] 3) Heat the stirred mixture to 160 degrees.

Embodiment 3

[0042] Embodiment three, a kind of preparation method of hot-melt adhesive for shoe material, comprises the following steps:

[0043] 1) Weigh raw materials, thermoplastic polyurethane elastomer 90kg, ethylene-ethyl acetate copolymer 10kg;

[0044] 2) Stir at room temperature;

[0045] 3) Heat the stirred mixture to 170 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com