Full-automatic glazing production line and full-automatic glazing process

A fully automatic, production line technology, applied in the field of glazing production line and glazing process, can solve the problems of affecting product quality, unable to meet the needs of mass production, affecting the quality of glazing, and reducing the labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

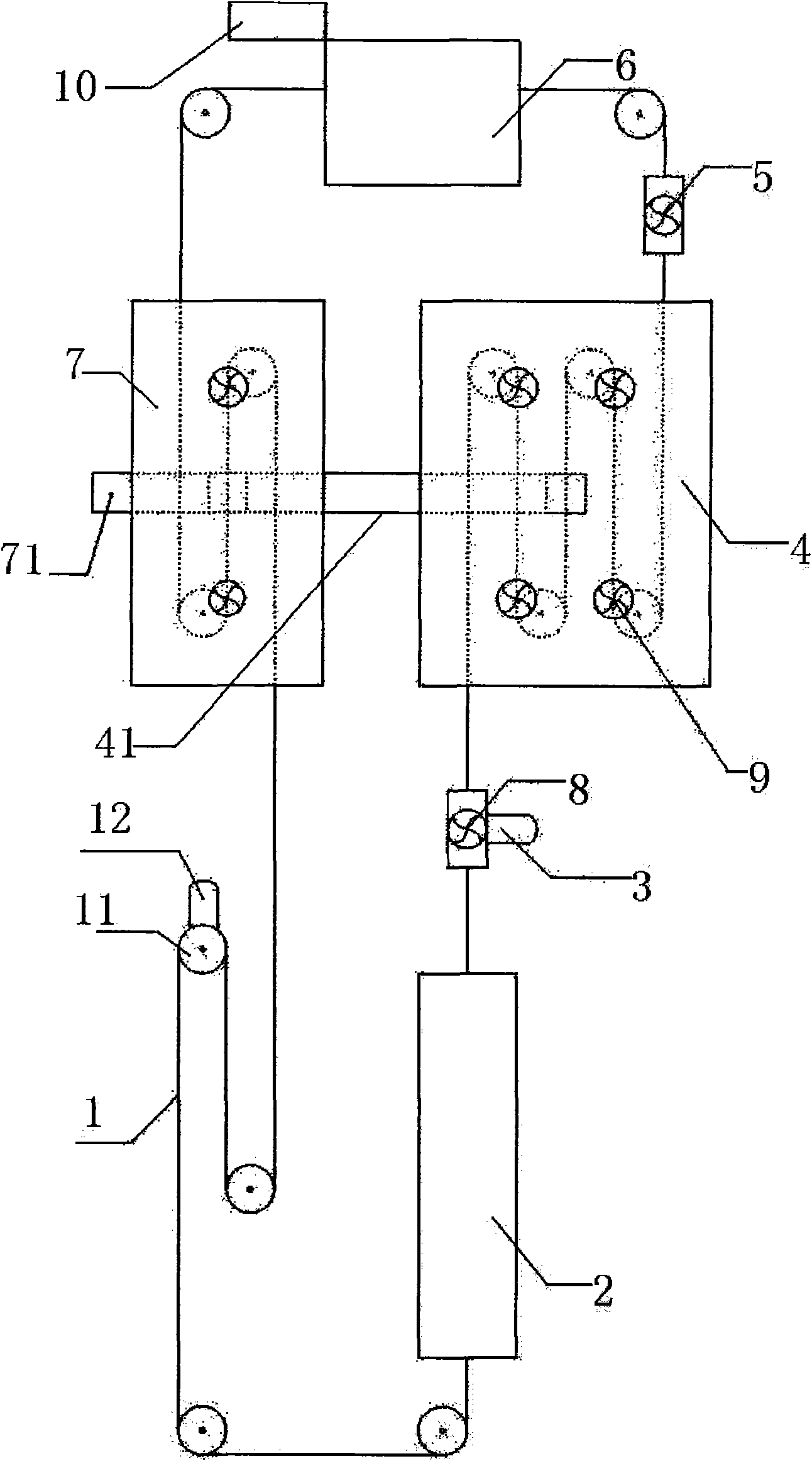

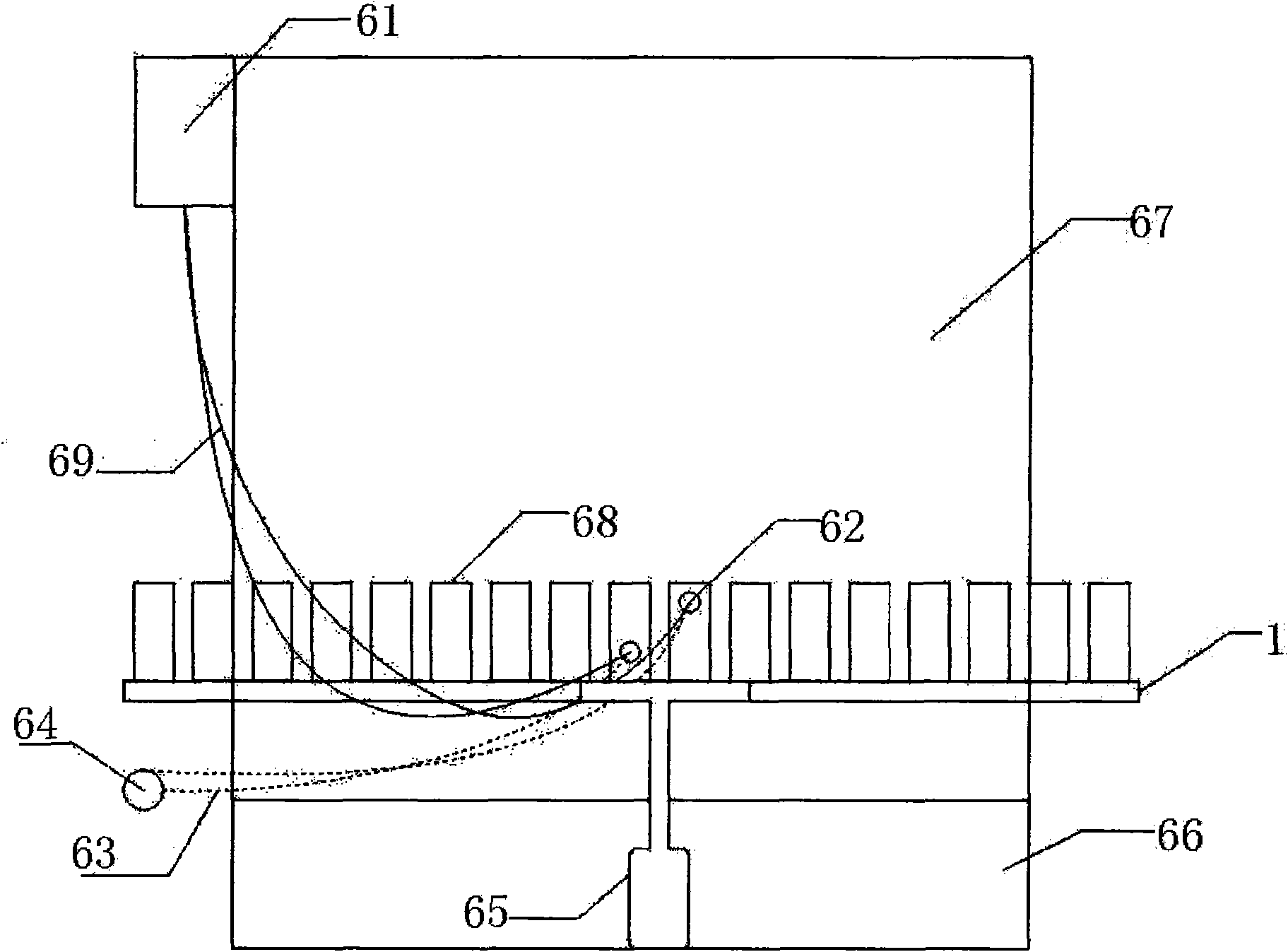

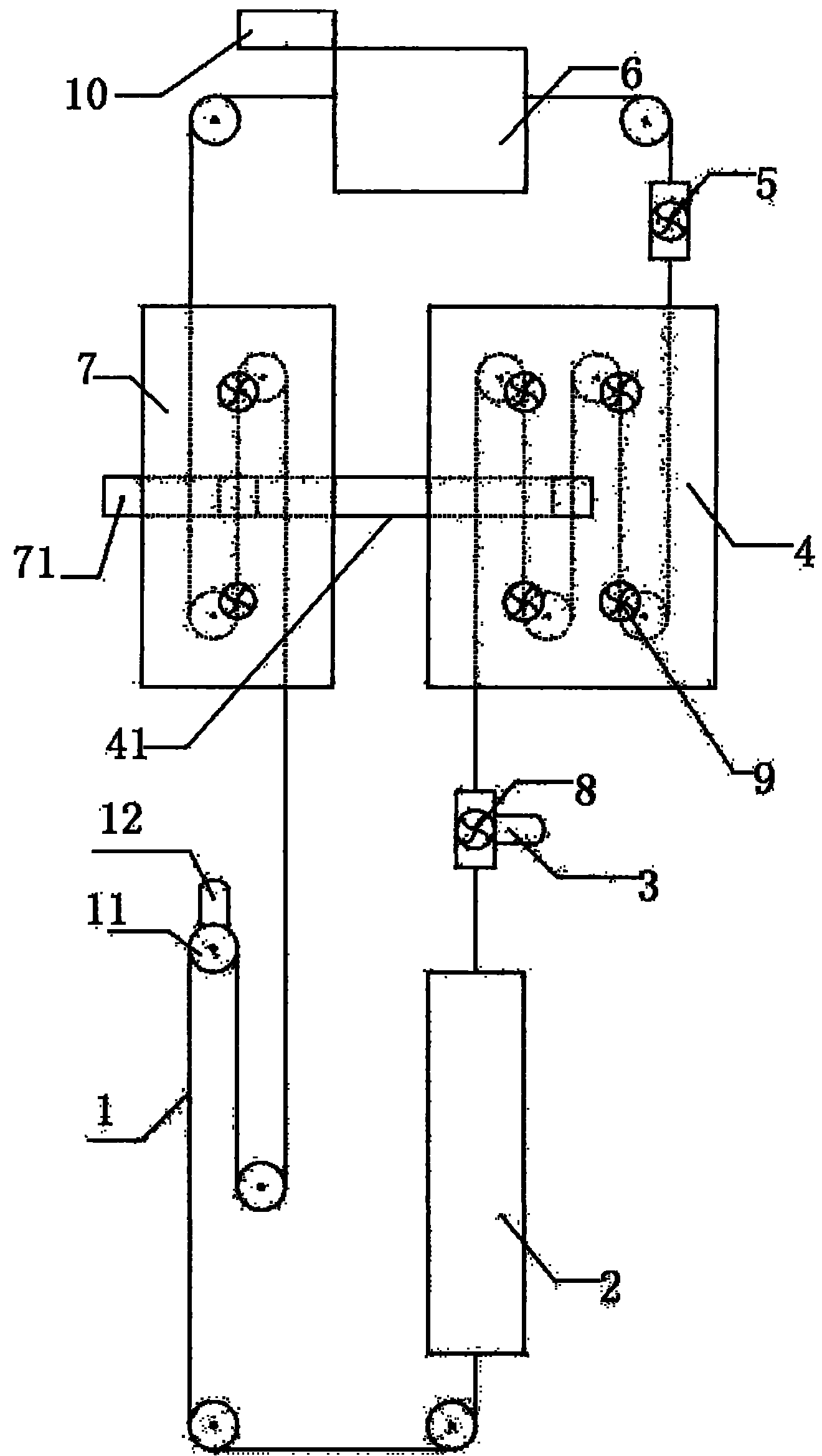

[0026] The full-automatic glazing production line and the full-automatic glazing process of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. as attached figure 1 As shown, the product conveyor belt 1 includes a plurality of sprockets 11 , a chain sleeved on the sprockets 11 , a conveyor belt laid on the chains, and one of the sprockets is connected to a driving motor 12 . Under the action of the driving motor 12, the conveyer belt circulates to convey products. Along the transmission direction of the product conveyor belt 1, there are successively an automatic cleaning cabinet 3, a motor-driven water rejection device 3, a numerically controlled dry water heater 4, a fan 5 for blowing cold air, an automatic glazing spray cabinet 6, and a numerically controlled curing furnace 7. A fan 8 for blowing cold wind is installed above the water rejection device 3 . One or more soaking blowers 9 of uniform hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com