Extraction method of cinnamon bark extract

An extraction method and extract technology, which are applied in chemical instruments and methods, food science, essential oils/spices, etc., can solve the problem that the utilization rate is only 1-2%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

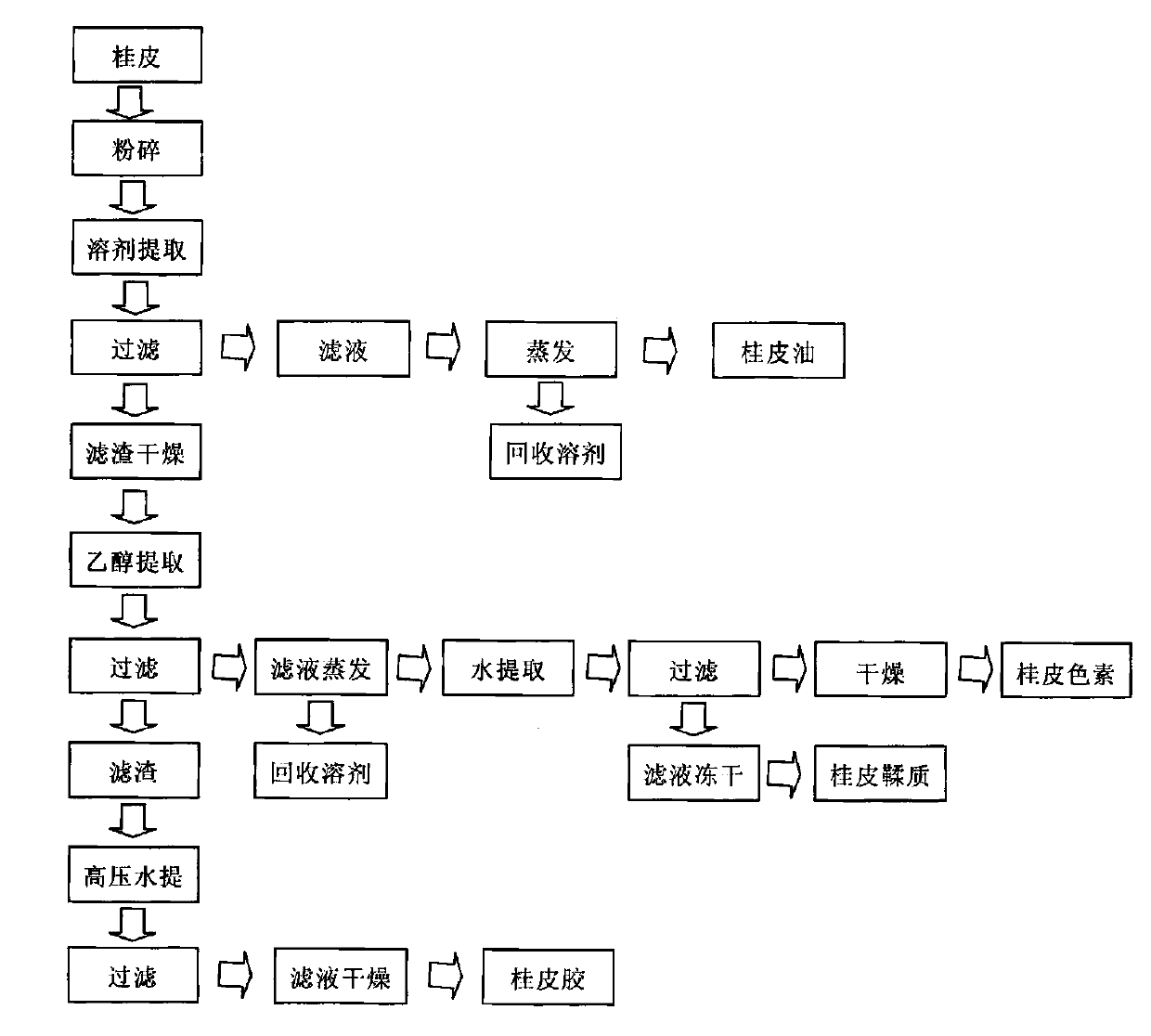

Method used

Image

Examples

Embodiment 1

[0017] Get the cassia bark powder 50kg that crossed 20 mesh sieves and join in the extraction kettle of 500L, with material-liquid ratio ( W / V ) 1:6 by adding petroleum ether, leaching at 35°C for 240 min, suction filtration to obtain the filtrate, and repeated extraction twice, the filtrates were combined and the solvent was recovered by the evaporator, and the yield of cassia bark essential oil was 0.37kg. The extraction kettle after extracting the essential oil is heated to 50° C., and the petroleum ether in the cinnamon powder is evaporated and recovered by vacuuming to obtain dry defatted cinnamon powder. Add the defatted cinnamon powder to the ratio of solid to liquid ( W / V ) 70% ethanol at a ratio of 1:4, leaching in a water bath at 35°C for 60 minutes, suction filtration, collecting the filtrate, and repeated extraction 4 times. When the substance content reaches 30%~50%, add water and stir to fully dissolve the soluble matter, filter to obtain the filtrate and filter...

Embodiment 2

[0019] Get 2kg of cassia bark powder that has passed through a 60-mesh sieve and add it to a 40L ultrasonic extractor. W / V ) at a ratio of 1:10, add petroleum ether, control the temperature below 40°C to extract for 30 minutes, and filter to obtain the filtrate, then add 4 times of petroleum ether for repeated extraction twice, combine the filtrates and recover the solvent through the evaporator, and the yield of cassia bark essential oil is 18.21 g. Heat the ultrasonic extractor to 50°C, vacuumize and stir to evaporate and recover the petroleum ether in the cinnamon powder to obtain dry defatted cinnamon powder. Add the defatted cinnamon powder into the ratio of solid to liquid ( W / V ) 1:8 concentration of 80% ethanol, leaching at 50°C for 60min, suction filtration, collecting the filtrate, and extracting once more, after combining the filtrate, it was concentrated in vacuum, and the concentration temperature was controlled below 50°C. When the substance content reaches 30%...

Embodiment 3

[0021] Get the cassia bark powder 100kg that crossed 40 mesh sieves and join in the chemical reactor, with solid-liquid ratio ( W / V ) at 1:10, add n-ethane, control the temperature at 40-50°C to extract for 90 minutes, filter to get the filtrate, add 4 times of n-ethane each time and extract twice, combine the filtrates and recover the solvent through the evaporator to obtain cinnamon essential oil The yield was 760 g. Evacuate and heat to 80°C to evaporate n-ethane in cinnamon powder and condense to recover n-ethane to obtain dry defatted cinnamon powder. Add the defatted cinnamon powder into the ratio of solid to liquid ( W / V ) 1:8 concentration of 75% ethanol, leaching at 45°C for 120min, suction filtration, collecting the filtrate, and extracting once again, the combined filtrate was concentrated in vacuum, the concentration temperature was controlled at 50°C, when the dry matter in the concentrate When the content reaches 50%, freeze-dry to obtain the mixture powder of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com