Preparation method for fluorescence carbon-based quantum dot

A carbon-based quantum dot and fluorescence technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficulty in expanding production, low yield, low yield, etc., and achieve the effect of improving quantum yield and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

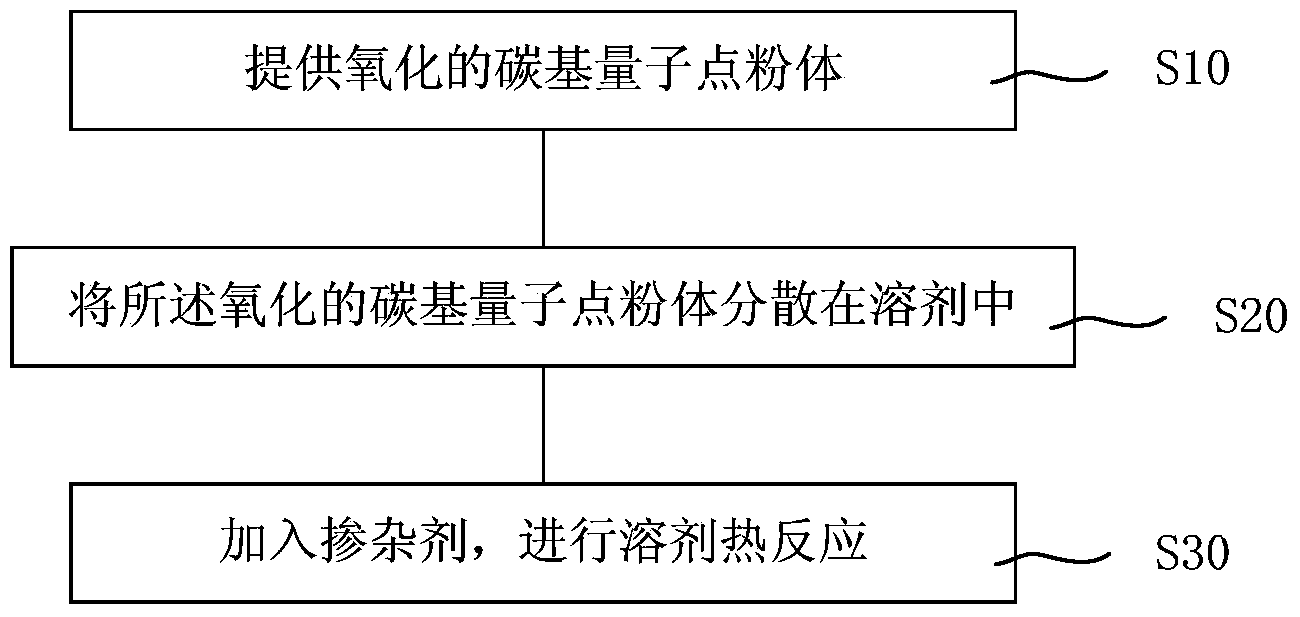

[0060] Such as figure 1 As shown, the preparation method of the fluorescent carbon-based quantum dots at least includes:

[0061] First, step S10 is performed: providing oxidized carbon-based quantum dot powder;

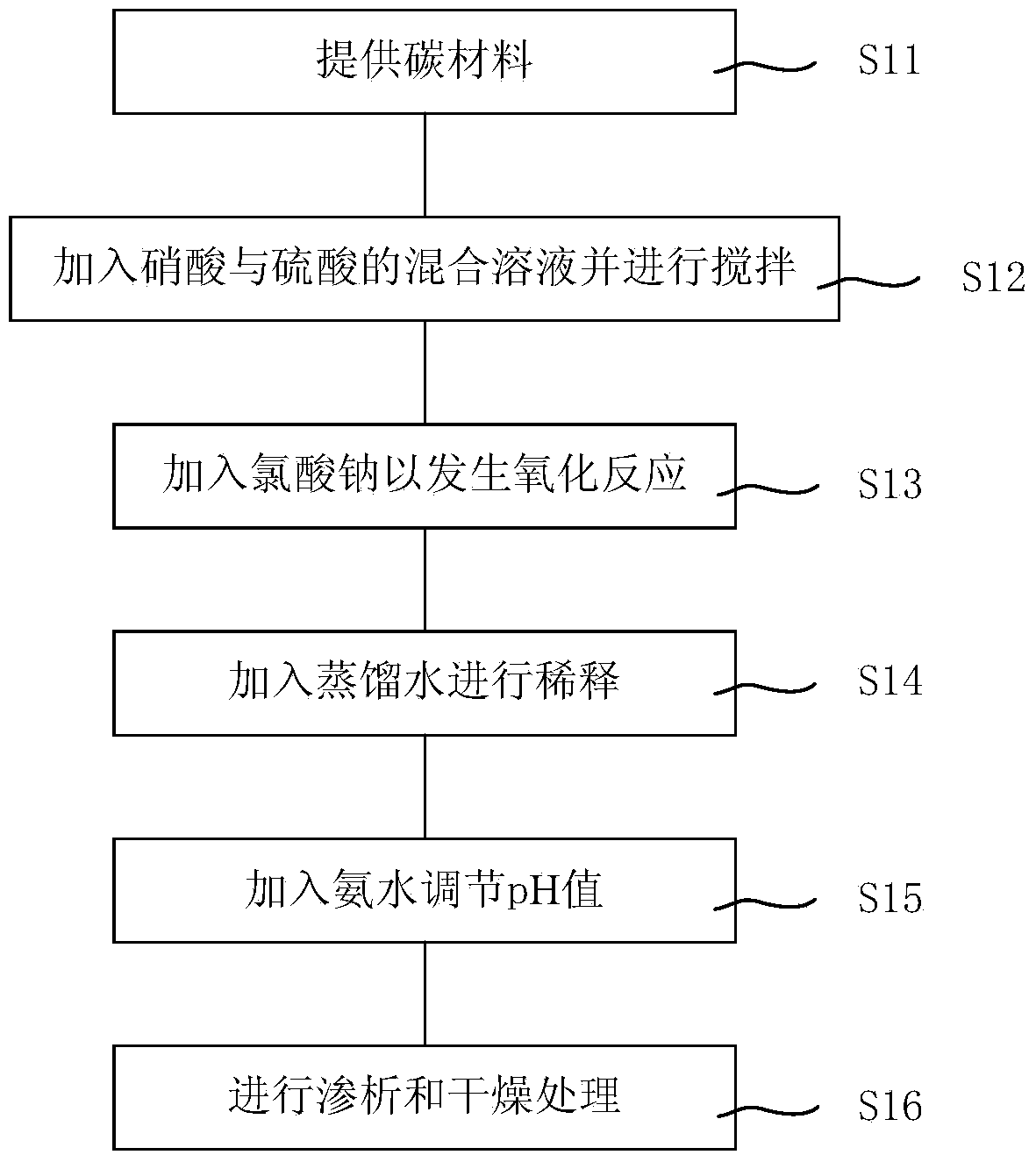

[0062] Wherein, the oxidized carbon-based quantum dot powder in this step can also be directly produced by carbon materials, specifically, combined with figure 1 ,refer to figure 2 Shown, the preparation method of the carbon-based quantum dot powder of described oxidation comprises:

[0063] Step S11: providing carbon material;

[0064] In this step, there is no specific requirement for the carbon material, and generally amorphous carbon, carbon black, graphene, graphene oxide, graphene nanosheets, fullerene, mesoporous carbon, or graphite can be used. Preferably, the carbon material is graphite, carbon black, graphene, graphene oxide, graphene nanosheets, fullerenes, mesoporous carbon or carbon nanotubes.

[0065] Step S12: adding a mixed solution of nitric ...

Embodiment 1

[0109] combine figure 1 and figure 2 , first, perform step S10: provide oxidized carbon quantum powder;

[0110] Specifically, in this embodiment, in this step, an oxidized carbon-based quantum powder is provided, including:

[0111] Step S11: Provide 25.000g of carbon black powder (particle size 20-50nm);

[0112] Step S12: Add the carbon black powder into a mixture of 285mL concentrated nitric acid (concentration: 67wt%) and 535mL concentrated sulfuric acid (concentration: 98wt%), mechanically stir at 5°C for 30min, and the stirring rate is 600r / min to form the first a mixed liquid;

[0113] Step S13: Slowly add 300g of NaClO to the first mixed liquid 3 In order to generate an oxidation reaction, control the reaction temperature of the oxidation reaction to 0-10°C, and react for 5 hours to form a second mixed liquid;

[0114] Step S14: Cool the second mixed liquid to room temperature, add 500 mL of distilled water to dilute to form a third mixed liquid, and filter it ...

Embodiment 2

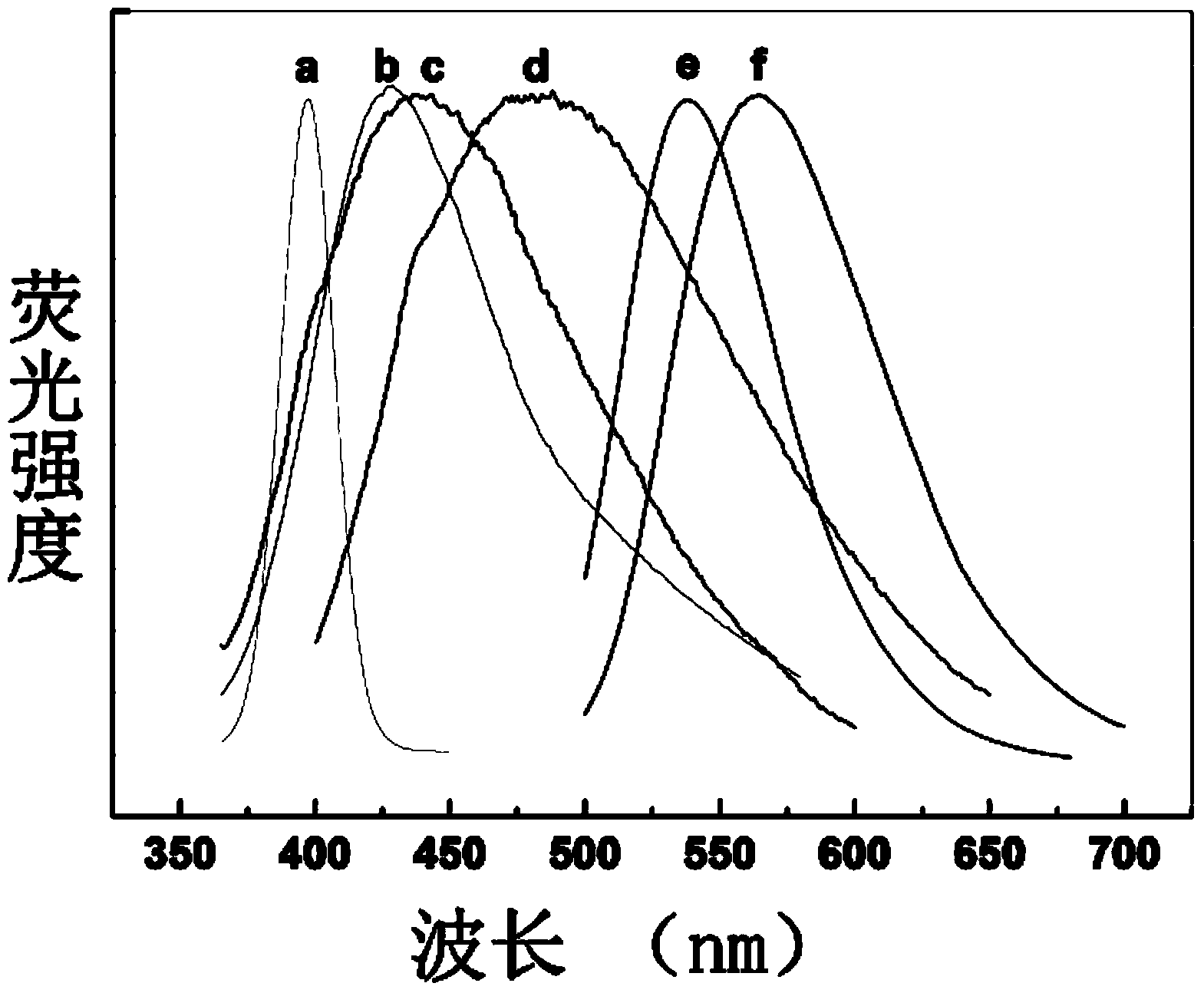

[0126] Change the carbon black in Example 1 to 25.000g graphene powder (1 to 5 atomic layers, the lateral dimension is 200-500nm), the dopant is changed to 0.050mL boron trifluoride ether solution, and other conditions are not changed. Change, B, F doped graphene quantum dots with an emission wavelength of 450nm can be obtained. This material can produce strong green fluorescence under ultraviolet light irradiation, with a quantum yield of 0.37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com