Method for repair and regeneration of waste lithium iron phosphate battery cathode material

A technology for lithium iron phosphate batteries and positive electrode materials, which is applied in battery recycling, solid waste removal, waste collector recycling, etc., to achieve the effects of clear recovery and repair objects, pollution mitigation, and clear battery brand names

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

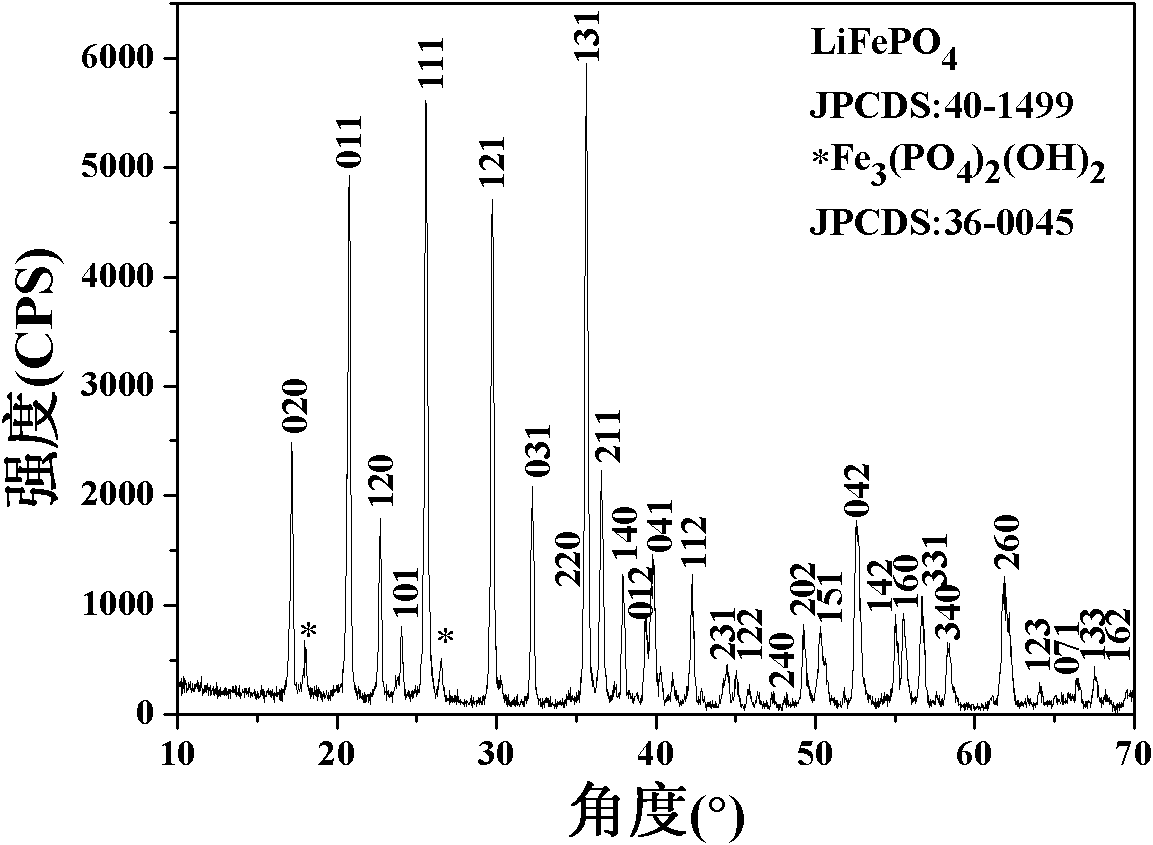

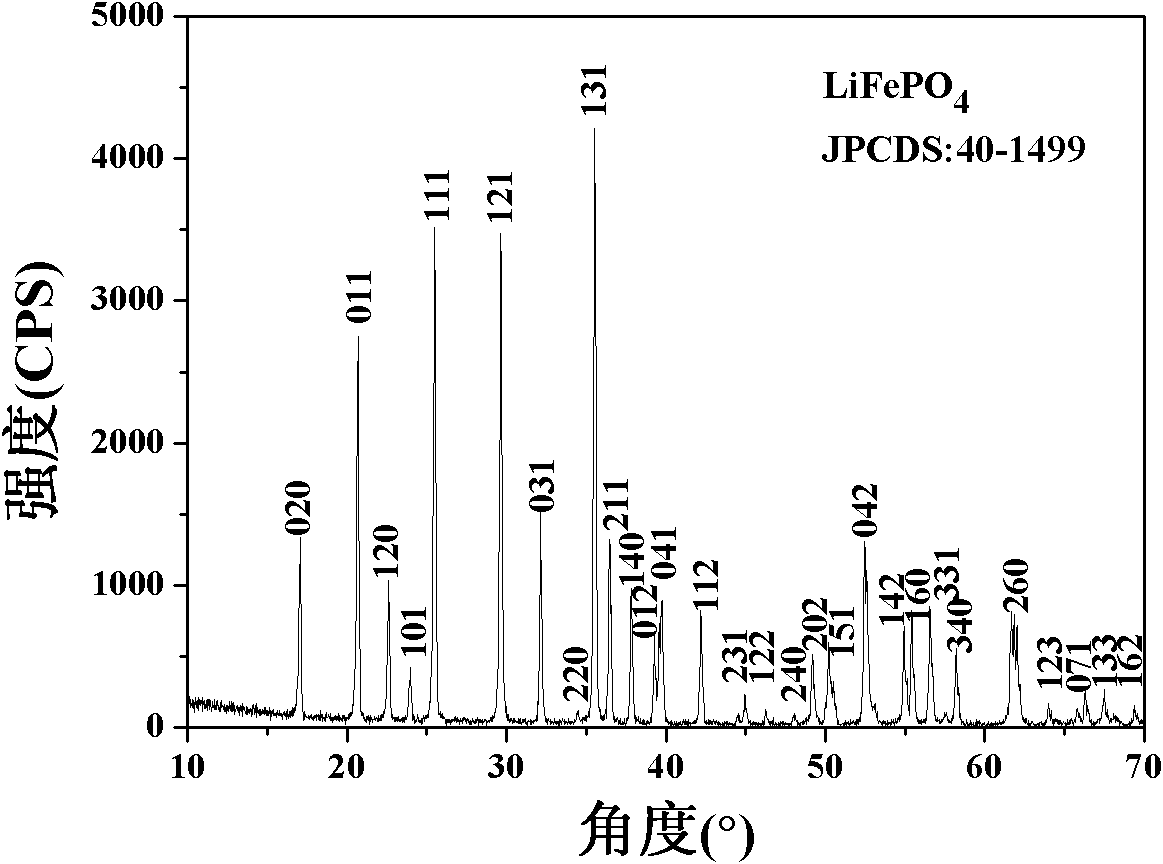

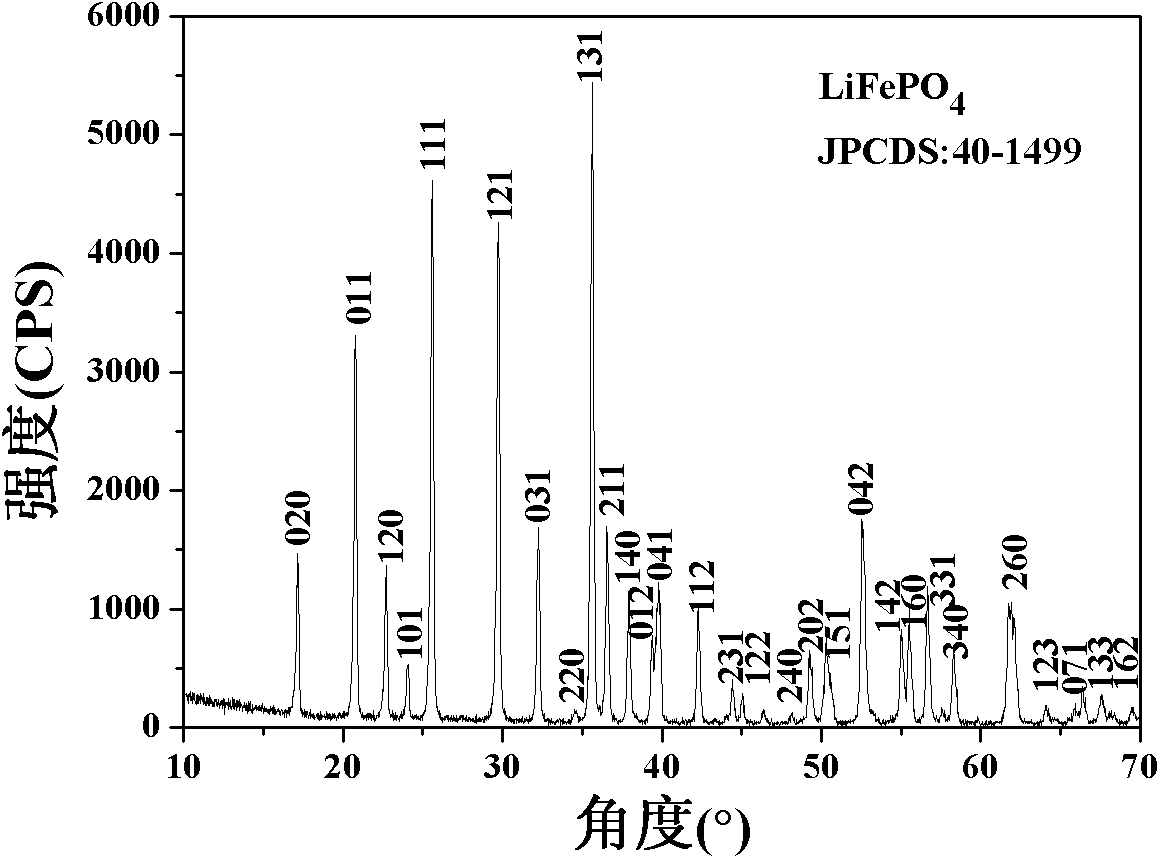

Image

Examples

Embodiment 1

[0043] Weigh 2.5g of the lithium iron phosphate positive electrode material to be repaired, place it in a 50mL autoclave, then add 30mL of lithium oxalate solution with a lithium ion concentration of 0.3mol / L and 0.01g of vitamin C in the autoclave, and then Close the autoclave and react at 170°C for 36 hours. After the reaction is completed, the product is centrifuged and dried to obtain a liquid-phase lithium supplement material. Add the liquid-phase lithium supplement material and 0.125g glucose into 5mL distilled water to disperse and mix uniformly, and then in a nitrogen atmosphere First calcined at 350°C for 2 hours, and then calcined at 550°C for 6 hours to obtain a repaired lithium iron phosphate positive electrode material.

[0044] According to the ratio of lithium iron phosphate active material: conductive agent: binder mass ratio of 90:5:5, the electrode sheet is made, the metal lithium sheet is used as the negative electrode, the Celgard 2400 polypropylene porous m...

Embodiment 2

[0046] Weigh 3g of the lithium iron phosphate cathode material to be repaired, place it in a 50mL autoclave, and then add 30mL of lithium ion concentration to the autoclave as a lithium chloride solution of 1mol / L and 0.005g of hydrazine (N 2 h 4 ), then close the autoclave and react at 200°C for 10 hours. After the reaction is completed, the product is centrifuged and dried, and the material after liquid phase lithium supplementation, 0.3g sucrose and 0.03g copper nitrate monohydrate are ball milled at a speed of 400r / min 3h, and then calcined at 350°C for 3h under a nitrogen atmosphere, and then calcined at 650°C for 7h to obtain a repaired lithium iron phosphate cathode material.

[0047] According to the ratio of lithium iron phosphate active material: conductive agent: binder mass ratio of 90:5:5, the electrode sheet is made, the metal lithium sheet is used as the negative electrode, the Celgard 2400 polypropylene porous membrane is used as the diaphragm, and 1mol / L LiPF ...

Embodiment 3

[0049] Weigh 2g of the lithium iron phosphate positive electrode material to be repaired, place it in a 50mL ball mill jar, then add 0.096g of lithium carbonate, 0.2g of glucose and 0.06g of copper oxide to the ball mill jar, according to the ball-to-material ratio of 1:30 , add 70g of agate balls and 5mL of ethanol, then seal the ball mill jar, ball mill at 400r / min for 6h, filter and dry the product after the reaction is completed, calcinate at 350°C for 5h under nitrogen atmosphere, and then calcinate at 600°C for 12h to repair Good lithium iron phosphate cathode material.

[0050] According to the ratio of lithium iron phosphate active material: conductive agent: binder mass ratio of 90:5:5, the electrode sheet is made, the metal lithium sheet is used as the negative electrode, the Celgard 2400 polypropylene porous membrane is used as the diaphragm, and 1mol / L LiPF 6 A mixed solution of ethylene carbonate (EC) and dimethyl carbonate (DMC) (volume ratio 1:1) was used as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com