Grapheme/rare earth oxide nanometer composite material and preparation method and application thereof

A technology of nanocomposite materials and rare earth oxides, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as no public reports, and achieve simple process, high conductivity, and improved The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

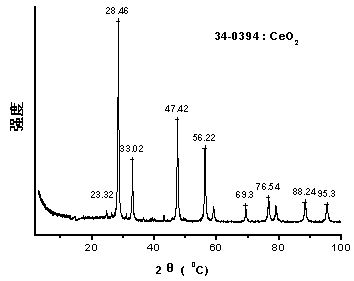

[0034] Example 1: Disperse 0.5g of graphene oxide in 100mL of distilled water and ultrasonicate for 2 hours; at the same time, weigh 0.5g of cerium chloride and dissolve it in 50mL of water, then mix and stir the two evenly, adjust the pH to 8, and sonicate for 5h , and then add 5mL of hydrazine hydrate to the mixed solution, pour it into a high-pressure hydrothermal kettle, heat up to 120°C, react for 12 hours, filter, wash, and freeze-dry to obtain a graphene / cerium oxide nanocomposite material. figure 1 , Figure 4 , Figure 7 They are the XRD diagram, SEM diagram and TEM diagram of the graphene / cerium oxide nanocomposite material respectively. From the above diagram, it can be clearly seen that the cerium oxide nanoparticles are spherically dispersed on the graphene surface, so that the graphene is well dispersed and No agglomeration, the spherical diameter of the cerium oxide nanoparticles is about 5-10nm, and the graphene sheet is 1-3 layers.

Embodiment 2

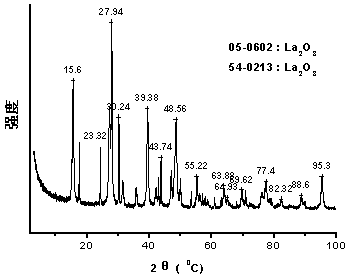

[0035] Example 2: Disperse 0.3g of graphene oxide in 100mL of distilled water and ultrasonicate for 1 hour; at the same time, weigh 0.6g of lanthanum chloride and dissolve it in 50mL of water, then mix and stir the two evenly, adjust the pH to 8, and sonicate for 3h , and then add 3mL of hydrazine hydrate to the mixed solution, pour it into a high-pressure hydrothermal kettle, raise the temperature to 150°C, and filter, wash, and freeze-dry after reacting for 8 hours to obtain a graphene / lanthanum oxide nanocomposite material. figure 2 , Figure 5 , Figure 8 They are the XRD diagram, SEM diagram and TEM diagram of the graphene / lanthanum oxide nanocomposite material respectively. From the above diagram, it can be clearly seen that nano-lanthanum oxide is dispersed on the surface of graphene in a rod shape, so that the graphene is well dispersed without Agglomerated, the diameter of the nano-lanthanum oxide rod is about 5-8nm, the diameter is about 30-50nm, and the graphene s...

Embodiment 3

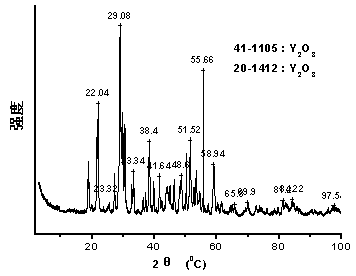

[0036] Example 3: Disperse 0.4 g of graphene oxide in 100 mL of distilled water, and ultrasonicate for 1 hour; at the same time, weigh 1.2 g of yttrium chloride and dissolve it in 50 mL of water, then mix and stir the two evenly, adjust the pH to 8, and sonicate for 5 hours , and then add 4mL of hydrazine hydrate to the mixed solution, pour it into a high-pressure hydrothermal kettle, heat up to 180°C, and filter, wash, and freeze-dry after reacting for 6 hours to obtain a graphene / yttrium oxide nanocomposite material. image 3 , Image 6 , Figure 9 They are the XRD diagram, SEM diagram and TEM diagram of the graphene / yttrium oxide nanocomposite material respectively. From the above diagram, it can be clearly seen that nano-yttrium oxide is dispersed on the surface of graphene in sheet form, so that graphene is well dispersed and No agglomeration, the diameter of the nanometer yttrium oxide sheet is about 50-100nm, the thickness is about 10-30nm, and the graphene sheet is 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com