A method for separating tungsten, molybdenum and bismuth in bismuth sulfide concentrate

A technology of bismuth sulfide, tungsten and molybdenum, which is applied in the direction of improving process efficiency, can solve the problems of complicated operation, high recovery cost, increased production cost and energy consumption, and achieves good comprehensive recovery benefit, low equipment material requirements, and processing time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

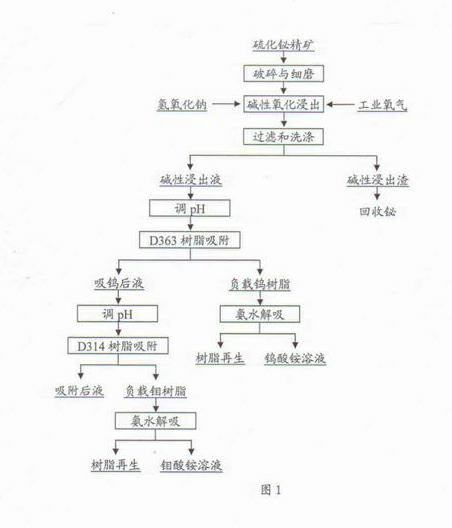

Image

Examples

Embodiment 1

[0027] Tungsten-containing molybdenum-bismuth sulfide concentrate finely ground to a particle size of less than 0.149mm, the main components of which are (%): Bi 32.86, Pb 1.1, Cu 2.07, S 23.18, WO 3 0.68, Mo1.40 and Fe14.03; industrial grade sodium hydroxide, in which the content of sodium hydroxide is ≥96%; industrial grade hydrochloric acid, in which the content of HCl is 36%~38%; industrial grade oxygen, in which O 2 Content ≥ 99%.

[0028] Make a solution of 91.0g of industrial sodium hydroxide with the above-mentioned components with 700ml of water and add 140g of bismuth sulfide concentrate with the above-mentioned components, after slurrying, add it to a pressure reactor with a volume of 1000ml, seal the reactor well, and adjust the stirring speed 800r.min -1 , and then gradually increase the temperature to 150°C. After the temperature and pressure are stabilized, introduce industrial oxygen, and keep the oxygen partial pressure at 0.5MPa for 3 hours. After reaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com