Sulfur group hetero-structure nano material, preparation method and application thereof

A technology of heterostructures and nanomaterials, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of expensive solvent, unfavorable large-scale preparation, toxicity, etc., and achieve the effect of simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Dissolve 0.154 grams of cadmium nitrate tetrahydrate, 0.158 grams of anhydrous bismuth trichloride, 0.133 grams of thiourea and 0.389 grams of polyvinylpyrrolidone in 35 milliliters of ethylene glycol at room temperature, and stir at room temperature until completely dissolved to obtain a homogeneous solution .

[0020] b. Transfer the mixed solution obtained in step a to a 50 ml stainless steel reaction kettle lined with polytetrafluoroethylene, and then heat at 140° C. for 8 hours under airtight conditions. After the reaction, the product was centrifuged, washed three times with acetone and deionized water, and dried at 60°C to obtain Bi 2 S 3 / CdS heterostructure, the molar ratio of bismuth source and cadmium source is 1:1

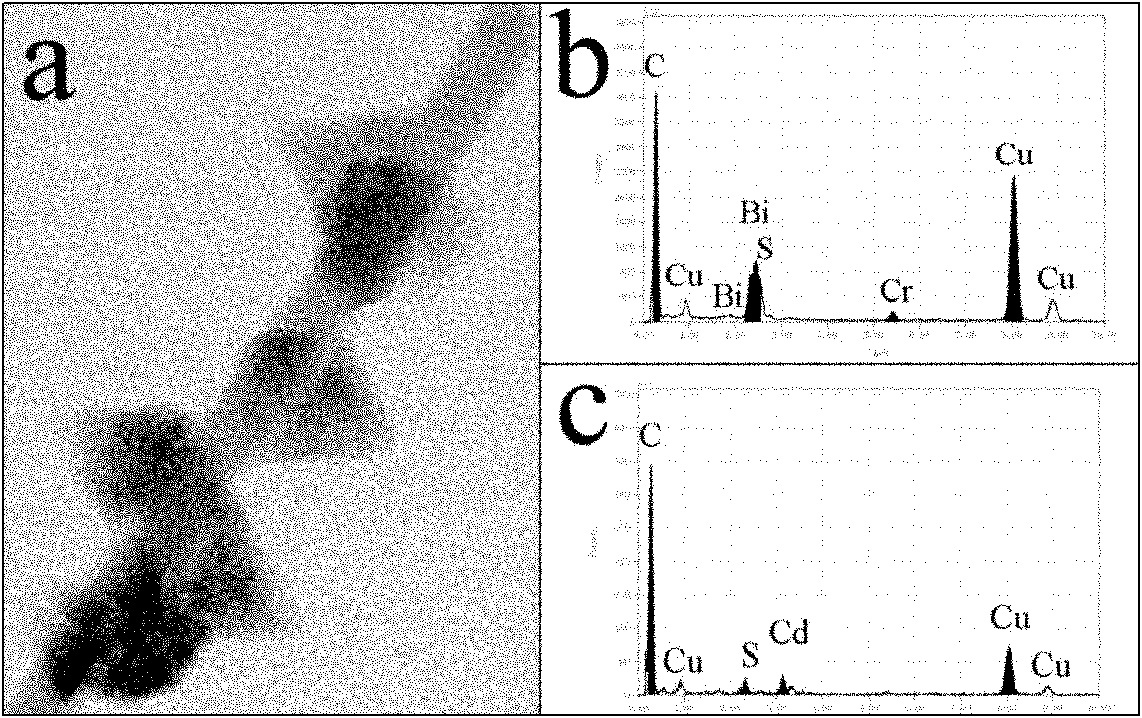

[0021] The result is as figure 1 and figure 2 Shown: figure 1 and figure 2 The result in (a) shows that the homogeneous heterostructure was obtained by this method. figure 2 The results of energy dispersion spectra in (b) and (c) sho...

Embodiment 2

[0023] a. Dissolve 0.154 g of cadmium nitrate tetrahydrate, 0.158 g of anhydrous bismuth trichloride, 0.114 g of thiourea and 0.333 g of polyvinylpyrrolidone in 35 ml of ethylene glycol at room temperature, and stir until completely dissolved to obtain a homogeneous solution at room temperature .

[0024] b. Transfer the mixed solution obtained in step a to a 50 ml stainless steel reaction kettle lined with polytetrafluoroethylene, and then heat at 140° C. for 8 hours under airtight conditions. After the reaction, the product was centrifuged, washed three times with acetone and deionized water, and dried at 60°C to obtain Bi 2 S 3 / CdS heterostructure.

Embodiment 3

[0026] a. Dissolve 0.154 grams of cadmium nitrate tetrahydrate, 0.158 grams of anhydrous bismuth trichloride, 0.152 grams of thiourea and 0.445 grams of polyvinylpyrrolidone in 35 milliliters of ethylene glycol at room temperature, and stir at room temperature until completely dissolved to obtain a homogeneous solution .

[0027] b. Transfer the mixed solution obtained in step a to a 50 ml stainless steel reaction kettle lined with polytetrafluoroethylene, and then heat at 140° C. for 8 hours under airtight conditions. After the reaction, the product was centrifuged, washed three times with acetone and deionized water, and dried at 60°C to obtain Bi 2 S 3 / CdS heterostructure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com