Method for preparing bismuth sulfide whiskers and the bismuth sulfide whiskers

A bismuth sulfide and whisker technology, which is applied in the field of preparation of bismuth sulfide whiskers, can solve the problems of poor controllability, sensitivity, inability to obtain the size and length of bismuth sulfide whiskers, and achieve easy concentration and dosage, concentration and dosage regulation, The effect of controllable product shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

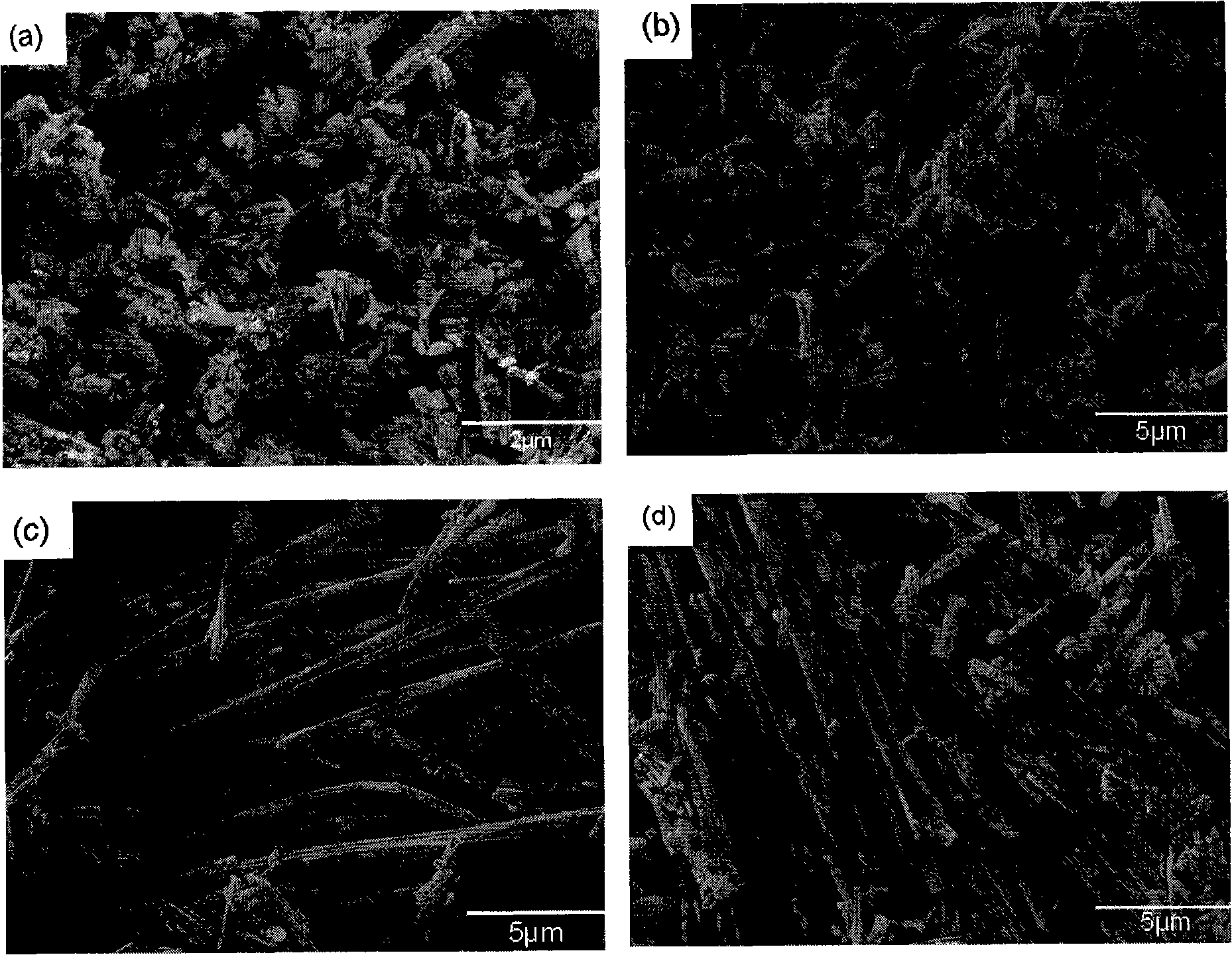

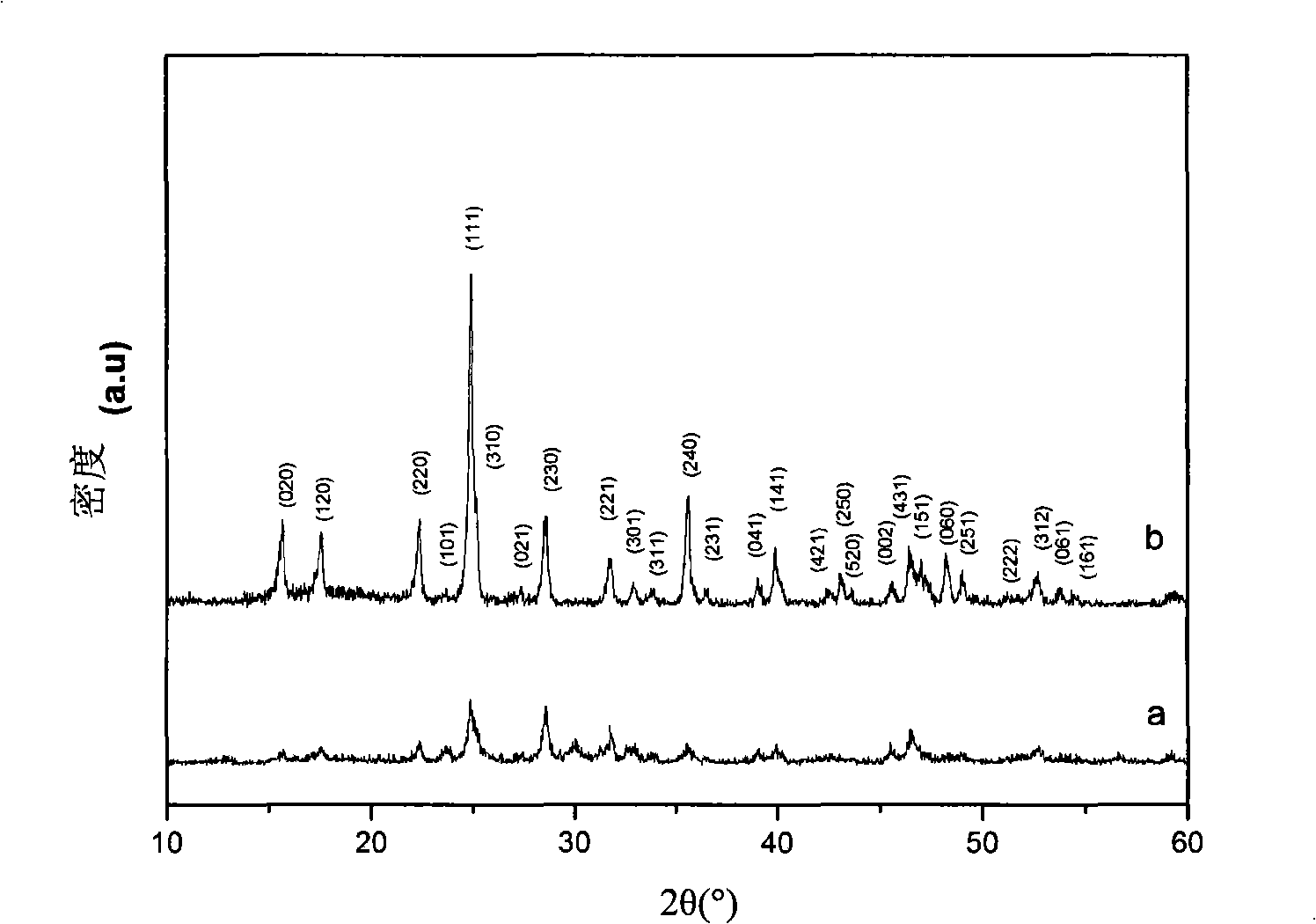

[0023] Weigh 0.002mol Bi(NO 3 ) 3 ·5H 2 O (0.9701 grams) and 0.004mol CS (NH 2 ) 2 (0.3045 grams) mix, and its molar ratio is 1: 2, adds LiOH solid 1.049 grams and 50ml distilled water, makes the concentration of LiOH in the mixture solution be 0.5M. Take 50ml of the above mixture (hydrothermal precursor) and stir it at room temperature for 1h, then transfer it to a 100ml polytetrafluoroethylene-lined autoclave, and conduct a hydrothermal reaction at 200°C for 16h to separate the precipitated product. The precipitated product was washed 3 times with distilled water and 3 times with absolute ethanol, and then dried in a vacuum oven at 70° C. for 4 hours to obtain a black powder product. The black powder was identified as orthorhombic Bi by X-ray diffraction (XRD). 2 S 3 . Scanning electron microscopy observations showed that the product Bi 2 S 3 The black powder is mostly composed of whiskers with a diameter of 100-500nm and a length of about 10μm and microcrystals com...

example 2

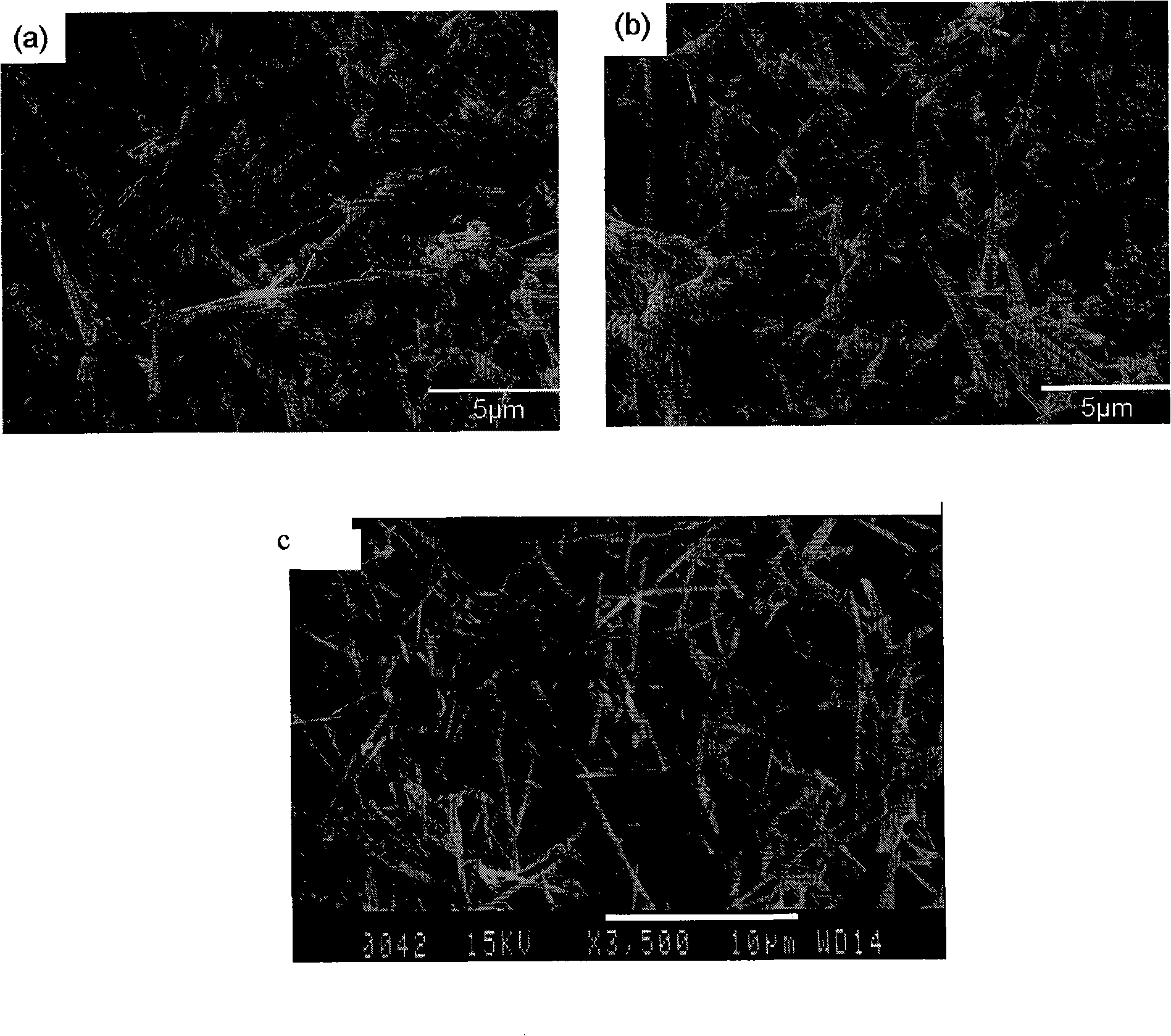

[0025] Weigh 0.002mol Bi(NO 3 ) 3 ·5H 2 O with 0.004mol CS(NH 2 ) 2 Mixing, the molar ratio is 1:2, add 2.098 g of LiOH solid and 50 ml of distilled water, so that the concentration of LiOH in the mixture solution is 1.0M to form a hydrothermal precursor. Take 50ml of the above mixture and stir it at room temperature for 1h, then transfer it to a 100ml polytetrafluoroethylene-lined autoclave, carry out hydrothermal reaction at 200°C for 16h, and separate the precipitated product. The precipitated product was washed 3 times with distilled water and 3 times with absolute ethanol, and then dried in a vacuum oven at 70° C. for 4 hours to obtain a black powder product. The product was identified as orthorhombic Bi by X-ray diffraction (XRD) 2 S 3 ,Such as image 3 (b) shown. Scanning electron microscopy observations showed that the product Bi 2 S 3 The black powder is composed of uniformly dispersed whiskers with an average diameter of 250nm and a length of about 20μm. S...

example 3

[0027] Other conditions are the same as in Example 2, wherein the concentration of LiOH in the hydrothermal precursor is 1.5M. The black powder product that obtains is identified as the Bi of orthorhombic phase through X-ray diffraction (XRD) 2 S 3 , scanning electron microscopy observations show that: Bi 2 S 3 Most of the product is composed of whiskers with a diameter of about 200-300 nm and a length of about 20 μm, with good uniformity (but not as good as the product in Example 2), and only a small part of particles exist. Such as figure 1 (d) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com