Multilevel structure bismuth sulfide, preparation method and application thereof

A technology of bismuth sulfide and reaction, applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of inability to obtain bismuth sulfide multi-level structure with high specific surface area, no application effect reported in literature, etc. problem, to achieve the effect of improving catalytic performance, uniform size and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

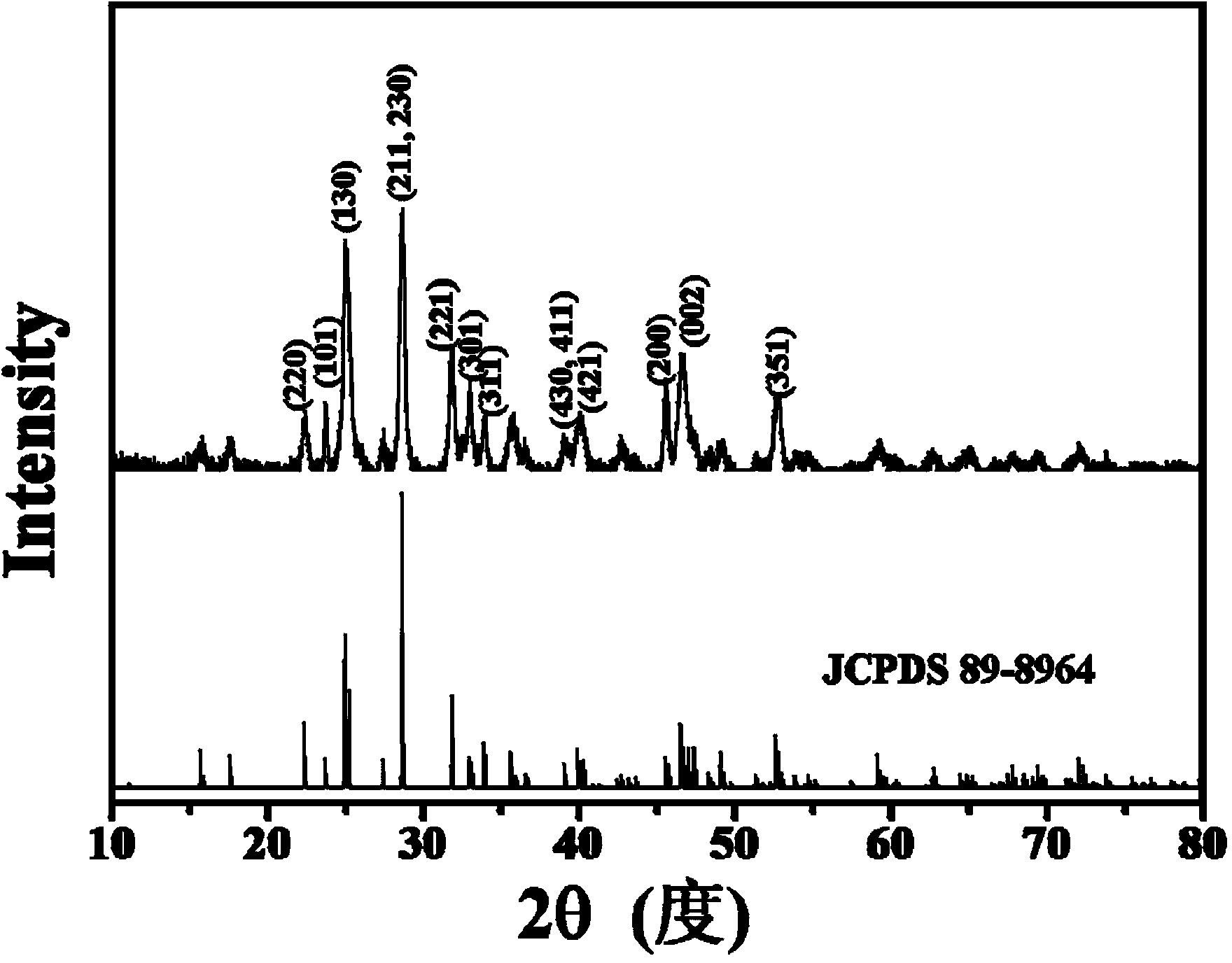

[0028] The preparation method of embodiment 1 multi-level structure bismuth sulfide, comprises the steps:

[0029] 1 mmol of bismuth nitrate pentahydrate and 1 mmol of 1-hexadecyl-3-methylimidazolium chloride ([C 16 MIMCl]) was dissolved in 50mL of ethanol (Ethanol), sonicated until completely dispersed. Then the reaction solution was placed in a microwave-ultrasonic combined reactor, the microwave power was set to 800W, the ultrasonic power was set to 1000W, and the reaction was carried out at a temperature of 180° C. for 10 minutes. Then 2 mmol thiourea was added into the reaction solution, and the reaction was continued for 15 min. After the reaction, the product was centrifuged and washed to remove residual solvent and excess organic matter on the surface, and finally dried at 60° C. for 24 hours to obtain a bismuth sulfide nanomaterial with a hierarchical structure. The specific surface area of the sample is 29.00m 2 / g, the light absorption range covers 200-800nm. ...

Embodiment 2

[0031] The preparation method of embodiment 2 multi-level structure bismuth sulfide, comprises the steps:

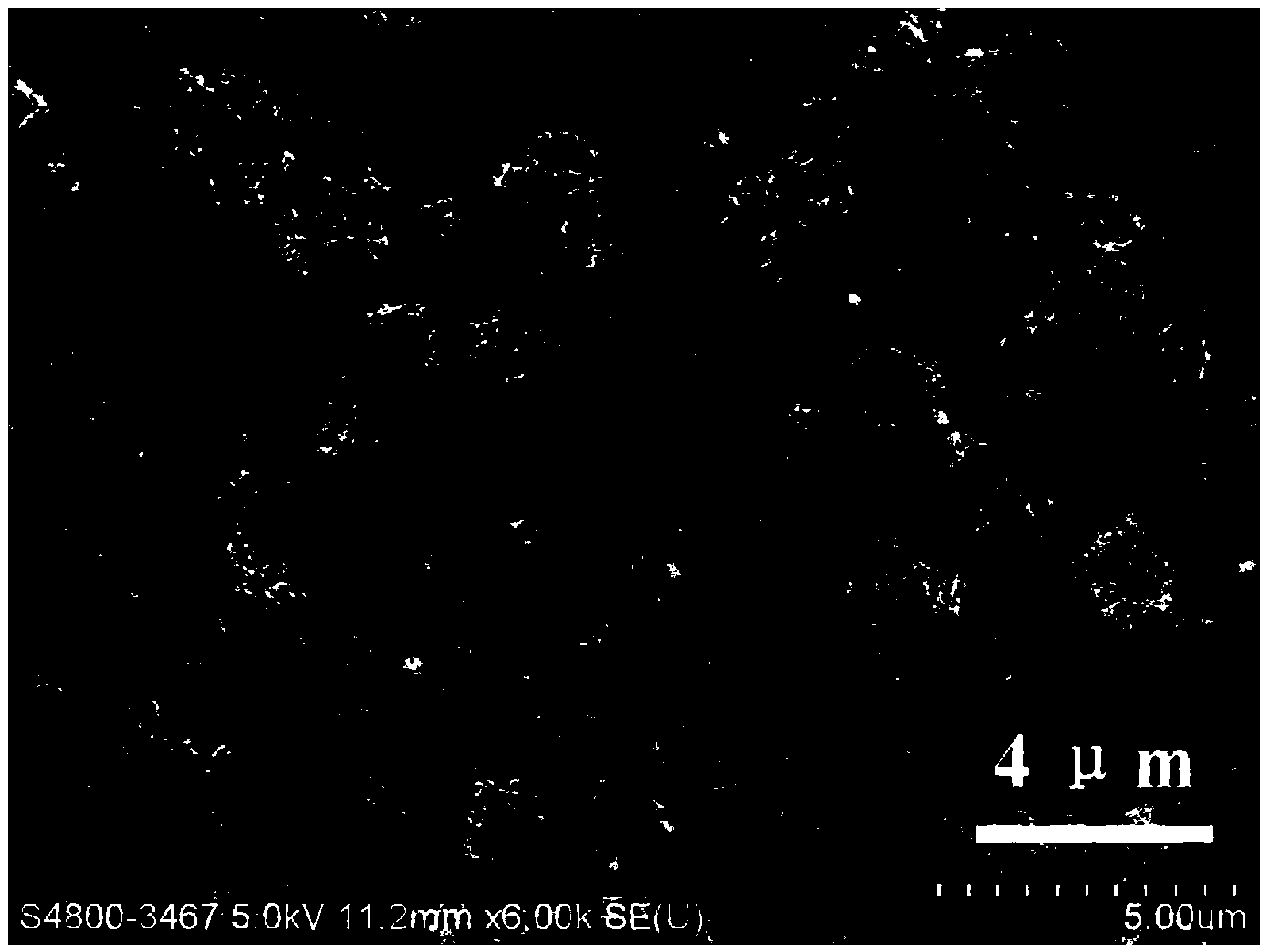

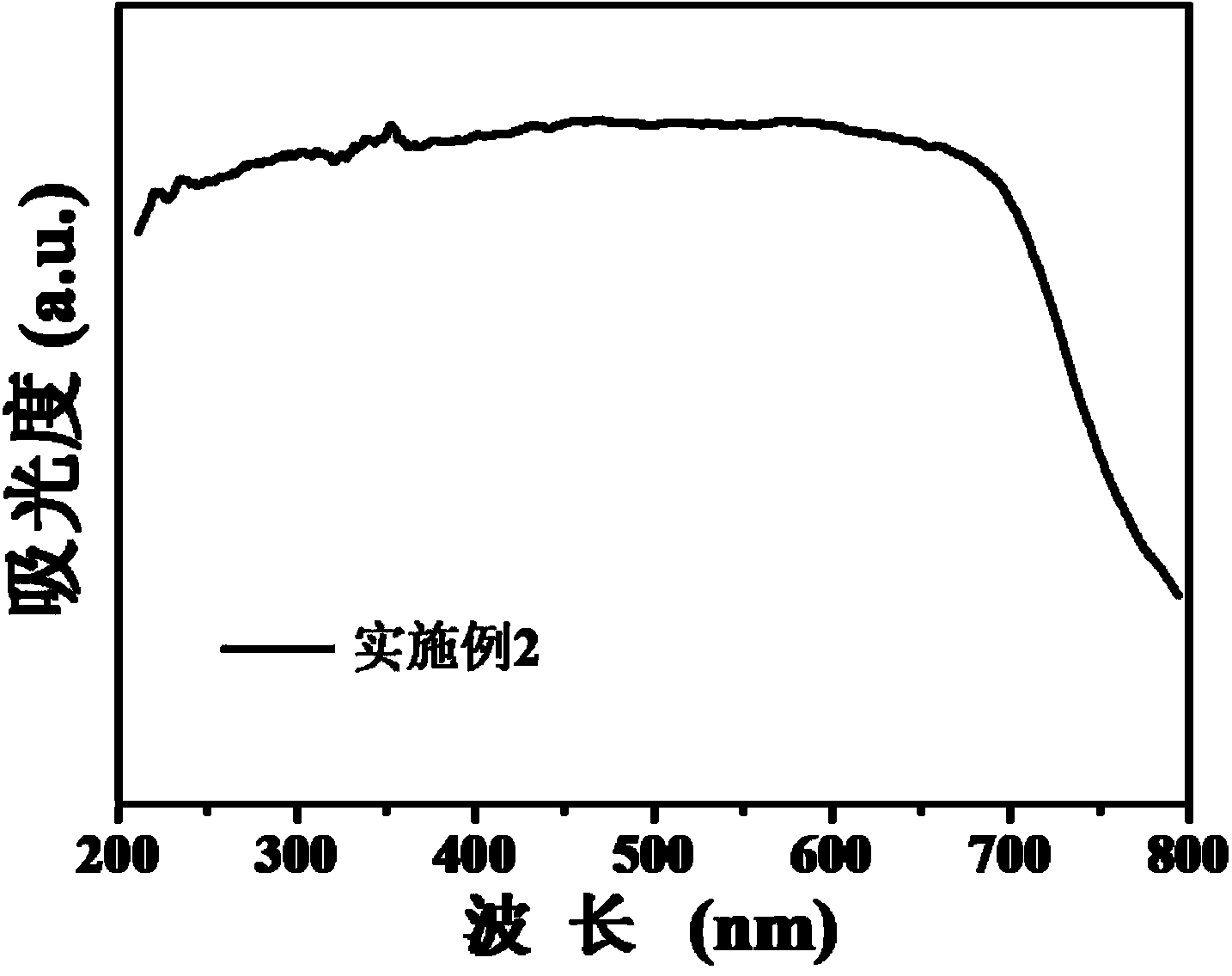

[0032] Dissolve 1.5 mmol of bismuth nitrate pentahydrate and 1.5 mmol of 1-butyl-3-methylimidazolium chloride ([BMIMCl]) in 80 mL of ethylene glycol (EG), and sonicate until completely dispersed. Then the reaction solution was placed in a microwave-ultrasonic combined reactor, the microwave power was set to 500W, the ultrasonic power was set to 200W, and the reaction was carried out at a temperature of 180° C. for 20 minutes. Then 3 mmol thiourea was added into the reaction solution, and the reaction was continued for 10 min. After the reaction, the product was centrifuged and washed to remove residual solvent and excess organic matter on the surface, and finally dried at 60° C. for 24 hours to obtain a bismuth sulfide nanomaterial with a hierarchical structure. The specific surface area of the sample is 31.10m 2 / g, the light absorption range covers 200-800nm.

[00...

Embodiment 3

[0035] The preparation method of embodiment 3 hierarchical structure bismuth sulfide, comprises the steps:

[0036] 0.5 mmol of bismuth nitrate pentahydrate and 0.5 mmol of 1-hexadecyl-3-methylimidazolium chloride ([C 16 MIMCl]) was dissolved in 20 mL of diethylene glycol (DEG), and sonicated until completely dispersed. Then the reaction solution was placed in a microwave-ultrasonic combined reactor, the microwave power was set to 1000W, the ultrasonic power was set to 800W, and the reaction was carried out at a temperature of 180° C. for 10 min. Then 1 mmol thiourea was added into the reaction solution, and the reaction was continued for 20 min. After the reaction, the product was centrifuged and washed to remove residual solvent and excess organic matter on the surface, and finally dried at 60° C. for 24 hours to obtain a bismuth sulfide nanomaterial with a hierarchical structure. The specific surface area of the sample is 29.76m 2 / g, the light absorption range covers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com