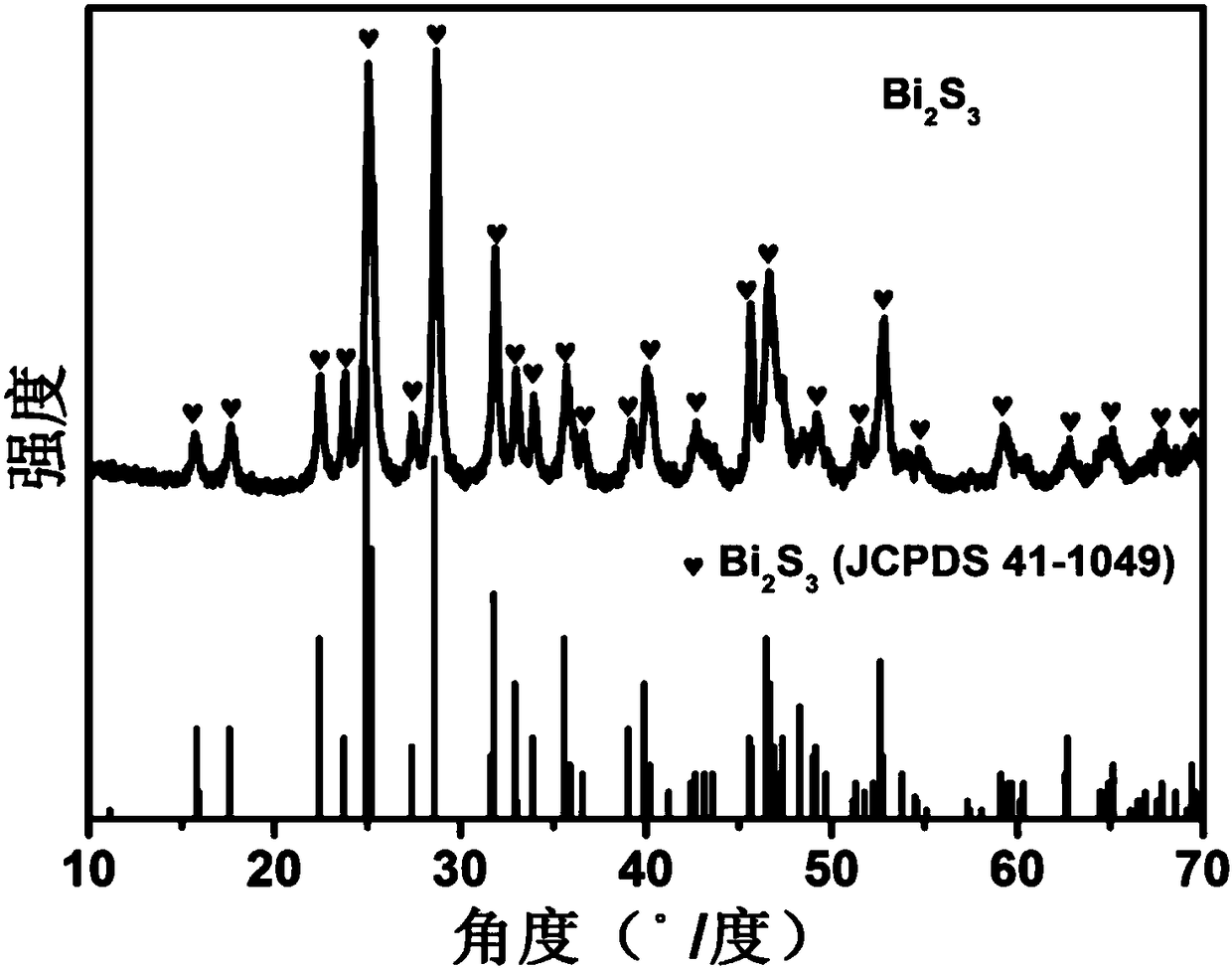

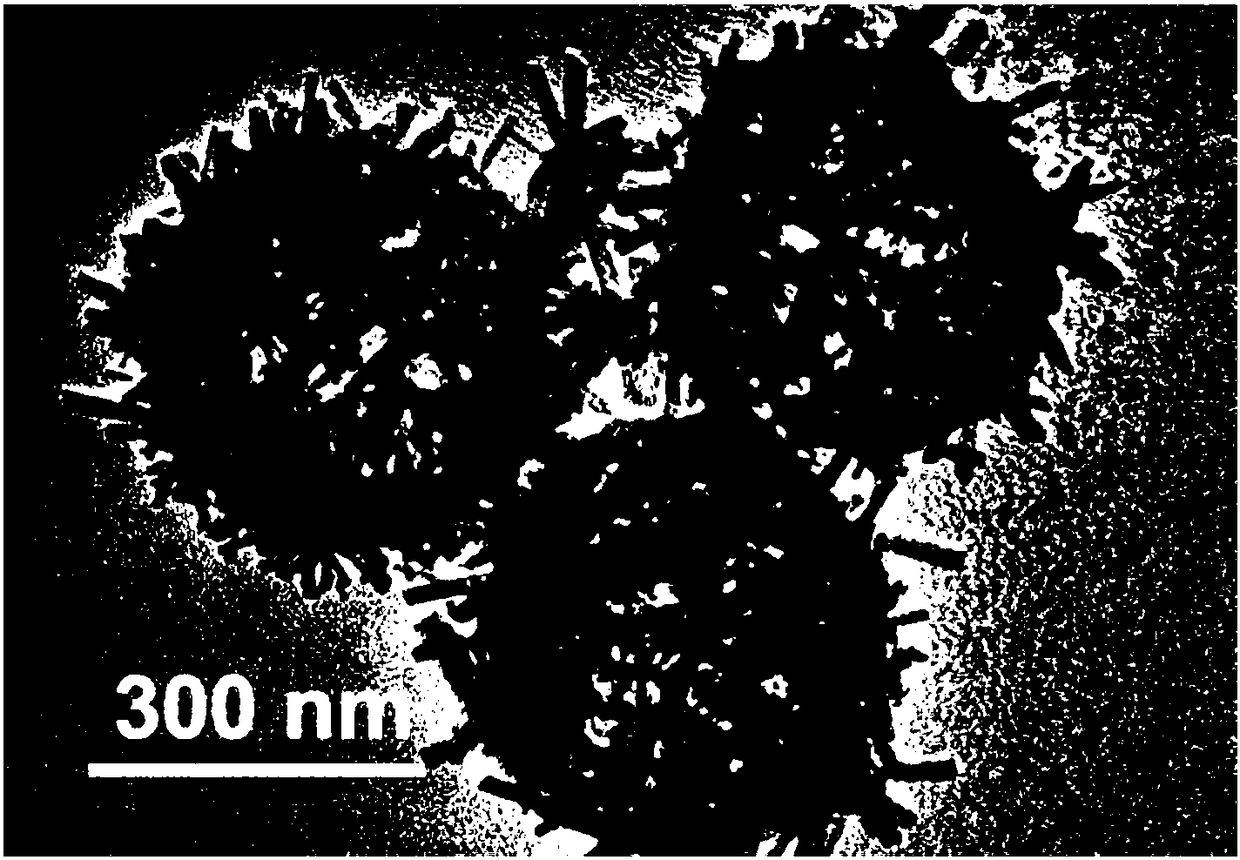

Rodlike bismuth sulfide hollow nanoscale balloon and preparation method thereof

A nano-microsphere, bismuth sulfide technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of complicated preparation methods, harsh conditions, complicated processes, etc., and achieve uniform product morphology and mild reaction conditions. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment prepares rod-shaped Bi according to the following steps 2 S 3 Hollow nanospheres:

[0033] a. Weigh 600mg of hexadecyltrimethylammonium bromide and place it in a 100mL round bottom flask, add 15mL of water for ultrasonic dispersion, then add 50mg of ascorbic acid, 300mg of zinc nitrate hexahydrate and 200mg of hexamethylenetetramine in sequence, and stir After dissolving, react at 95°C for 15h; naturally cool to room temperature, centrifuge, wash with ethanol three times, and dry at 60°C for 12h to obtain monodisperse ZnO nanospheres.

[0034] b. Weigh 500mg of monodisperse ZnO nanospheres in a 25mL round bottom flask, seal and vacuumize, then transfer it to an oil bath at 60°C for insulation; subsequently, add H 2 S gas was introduced into the round-bottomed flask, reacted for 8 hours, cooled naturally to room temperature, washed 3 times with ethanol, and dried at 60°C for 12 hours to obtain monodisperse ZnS nanospheres with hierarchical porous structur...

Embodiment 2

[0043] This embodiment prepares rod-shaped Bi according to the following steps 2 S 3 Hollow nanospheres:

[0044] a. Weigh 550mg of cetyltrimethylammonium bromide and place it in a 100mL round bottom flask, add 15mL of water for ultrasonic dispersion, then add 40mg of ascorbic acid, 250mg of zinc nitrate hexahydrate and 150mg of hexamethylenetetramine in sequence, and stir After dissolving, react at 90°C for 12h; naturally cool to room temperature, centrifuge, wash with ethanol three times, and dry at 60°C for 12h to obtain monodisperse ZnO nanospheres.

[0045] b. Weigh 400mg of monodisperse ZnO nanospheres in a 25mL round bottom flask, seal and evacuate, then transfer it to an oil bath at 55°C for insulation; subsequently, add H 2 S gas was introduced into the round-bottomed flask, reacted for 7h, cooled naturally to room temperature, washed with ethanol three times, and dried at 60°C for 12h to obtain monodisperse ZnS nanospheres with hierarchical porous structure.

[00...

Embodiment 3

[0051] This embodiment prepares rod-shaped Bi according to the following steps 2 S 3 Hollow nanospheres:

[0052] a. Weigh 500mg of cetyltrimethylammonium bromide and place it in a 100mL round bottom flask, add 15mL of water for ultrasonic dispersion, then add 30mg of ascorbic acid, 200mg of zinc nitrate hexahydrate and 110mg of hexamethylenetetramine in sequence, and stir After dissolving, react at 85° C. for 10 h; naturally cool to room temperature, centrifuge, wash with ethanol three times, and dry at 60° C. for 12 h to obtain monodisperse ZnO nanospheres.

[0053] b. Weigh 300mg monodisperse ZnO nanospheres in a 25mL round bottom flask, seal and vacuumize, then transfer it to an oil bath at 50°C for insulation; subsequently, add H 2 S gas was introduced into the round-bottomed flask, reacted for 6h, cooled naturally to room temperature, washed with ethanol three times, and dried at 60°C for 12h to obtain monodisperse ZnS nanospheres with hierarchical porous structure.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com